Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Raw materials: Limestone

Capacity: 30-60tph

Feed size: <400mm

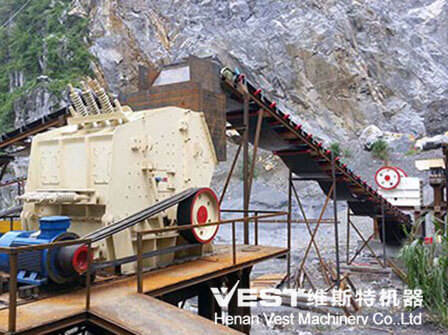

The 30-60t/h limestone crushing production line, which consists of PE400×600 jaw crusher, PF1007 impact crusher and 3YKR1237 vibrating screen, can meet the crushing and screening needs of limestone and other stones. If there is a need for sand making, a VSI sand making machine can also be configured.

If you have any questions,you can ask customer service online !

• Jaw crusher machine are currently widely used in mining, construction, metallurgy, roads, railways and other fields. They can crush medium and high hardness stones with a strength of less than 320Mpa, including quartz, granite, basalt, limestone, etc.

• PE jaw crusher is a classic crushing equipment with the characteristics of large crushing ratio, uniform product particle size, durability, easy maintenance and wide range of use. It squeezes materials through the relative movement of the moving jaw and the fixed jaw. It is widely used in mining, construction and other industries and can efficiently crush stones of various hardness.

• The PFW1007 impact crusher has a feed size of ≤300mm, a processing capacity of 20-60t/h, and a motor power of 37-55kw. It is suitable for crushing medium-hard materials and can meet the needs of a 50-60t/h stone crushing production line.

• PFW impact crusher machine adopts advanced technology and unique structural design. The crushed materials are cubic, without extension, cracks and more perfect particle shape. In addition, it is made of high chrome plate, which is more wear-resistant and has a longer service life. .

• The whole set of equipment has superior performance and can meet the production needs of 30-60t/h.

• The production line can be flexibly configured and the relevant equipment configuration can be adjusted according to the actual needs of the user.

• The production line is also suitable for crushing other stone materials, including limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregates, etc.

30-60tph Limestone Stone Crushing Line

1. Use an excavator to feed the raw materials with a size of less than 300mm onto the vibrating feeder, and then feed them into the primary jaw crusher evenly and stably.

2. The jaw crusher uses the extrusion of raw materials caused by the movement of the jaw plate to crush the stone into a certain size.

3. The crushed stones will be sent to the impact crusher by the belt conveyor for secondary crushing, and the crushed materials will be sent to the vibrating screen.

4. The vibrating screen will screen the qualified finished products into different size ranges, such as 0-5mm, 5-15mm, 15-40mm, etc.

5. The installation angle of the belt conveyor is usually <17°. It is the core conveying equipment of the entire stone crushing production line.