Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Raymond mill is a kind of equipment that realizes fine powder processing through the centrifugal rolling of grinding rollers and airflow classification. It is suitable for the dry grinding of non-flammable and explosive materials (such as limestone, calcite, barite, gypsum, calcium carbonate, etc.) with Mohs hardness ≤7.5 and humidity ≤8%.

Raymond mill can crush calcite, limestone, kaolin and other stone materials. The feed particle size is less than 30mm, and fine powder between 80-325 mesh can be produced. The hourly output is 0.5-60 tons.

Raymond mill has low power consumption, which is 30-50% lower than traditional mill. It occupies a small area and has low investment cost, making it suitable for large-scale production.

The finished product particle size can be adjusted arbitrarily within the range of 60-325 mesh (80μm~44μm). Different fineness requirements can be achieved by adjusting the analyzer or air volume control valve, and the screening rate is as high as 99%.

It uses high-quality steel and high-performance wear-resistant components (such as grinding rollers and grinding rings), and its service life is 3-5 times longer than that of traditional equipment. The transmission system is closed and stable, with low vibration and easy maintenance.

It is suitable for non-flammable and explosive materials with Mohs hardness ≤7.5 and humidity ≤8%, covering the grinding and processing of more than 170 kinds of ores and industrial raw materials in the fields of building materials, chemical industry, metallurgy, etc.

Raymond mill can process limestone and other raw materials for cement production; in the chemical industry, it can grind kaolin and other materials to provide fillers for coatings; in the metallurgical and electric power industries, it is used to grind ore powder and coal powder to improve smelting efficiency and power generation efficiency; it can also process corresponding raw materials in the pharmaceutical and food industries.

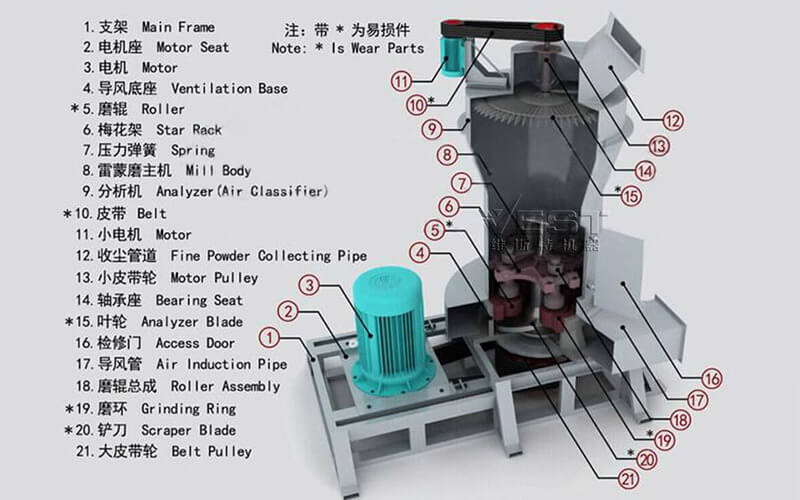

After the material enters the Raymond mill through the feeding system, it is lifted by the rotating scraper to the space between the grinding roller and the grinding ring and crushed by the centrifugal rolling action of the grinding roller.

The crushed fine powder rises to the classifier with the air flow, and the particles that meet the fineness requirements are discharged as finished products through the collector, and the coarse powder falls back to be re-ground, forming a closed cycle.

The system can precisely control the particle size of finished products (e.g., 60-325 mesh) by adjusting the analyzer speed or air volume, thus realizing efficient grinding and classification integration.

*The output will vary according to different materials, feed particle size and other factors

| Model | Roller | Roll Dia. (mm) | Roll Ring Size (mm) | Max. Input Size (mm) | Output Size (mm) | Capacity t/h | Power (Kw) | Dimension | |

| 3R | 1510 | 3 | 150*100 | 570*100 | 15 | 0.125-0.044 | 0.8-10 | 7.5 | 3200*1200*3800 |

| 2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 1-12 | 15 | 3500*3300*4500 | |

| 2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 1.5-20 | 18.5 | 4650*3600*5100 | |

| 2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 2-28 | 22 | 4700*3600*5100 | |

| 3015 | 3 | 300*150 | 875*150 | 25 | 0.125-0.044 | 2-35 | 30 | 5300*4100*5200 | |

| 4R | 3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 3-36 | 30 | 5400*4100*5200 |

| 3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 4-45 | 37 | 7100*5900*7900 | |

| 3220 | 4 | 320*200 | 970*200 | 25 | 0.125-0.044 | 4-55 | 45 | 9900*5800*1058 | |

| 5R | 4119 | 5 | 410*190 | 1270*190 | 30 | 0.613-0.044 | 8-60 | 75 | 9200*7250*9700 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.