Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

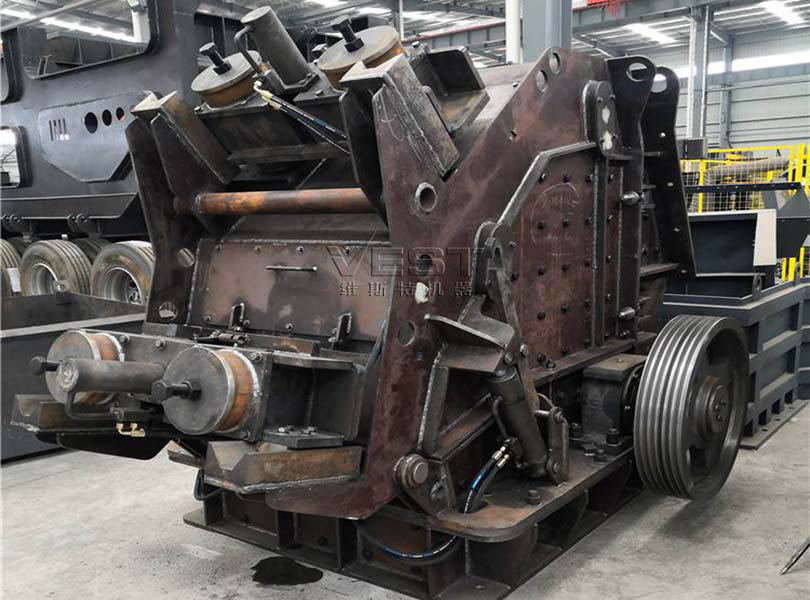

CI large-mouth impact crusher is suitable for crushing stones with medium hardness or below, such as limestone, dolomite, shale, coal gangue, etc. It is widely used in construction aggregate production, road engineering construction, ore crushing and other fields.

CI large-mouth impact crusher has a maximum compressive strength of up to 350MPa, a feed size of 400-900mm, and a discharge particle size of about 5-40mm. It can produce 12-stone with a size of 10-20mm and 24-stone with a size of 10-15mm, etc., which can meet the discharge particle size requirements of different users.

CI large impact crusher is widely used in sand and gravel yards, mining, concrete mixing plants, dry mortar and other fields.

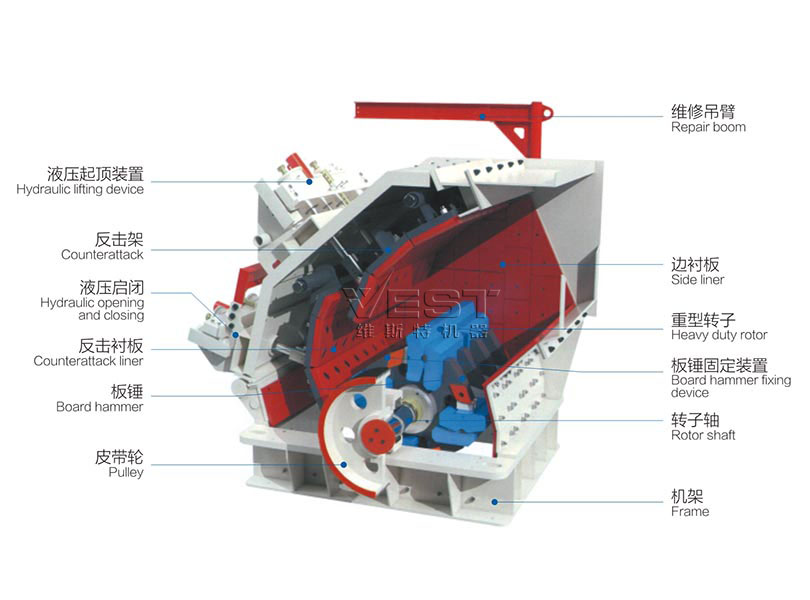

The unique large feed opening design allows large pieces of material to enter directly, greatly improving the feeding efficiency and reducing the initial crushing steps.

The high-speed rotor combined with the special crushing chamber generates a strong impact force, efficiently crushing all kinds of materials and significantly improving production capacity.

Thanks to the precisely designed impact plate and material movement trajectory, the output material has a regular cubic shape and meets high-grade material standards.

The overall structural design fully considers maintenance needs, and wearing parts are easy to replace, greatly reducing maintenance difficulty and downtime.

CI large-mouth impact crusher is mainly used in the field of ore crushing. It can efficiently crush various metal and non-metallic ores and provide raw materials of suitable particle size for subsequent processing. At the same time, it also plays an important role in construction and road engineering, and can produce high-quality aggregates and crushed stones to meet the needs of related engineering construction.

The material falls vertically from the top of the machine into the high-speed rotating impeller. Under the action of high-speed centrifugal force, it collides and is crushed with the other part of the material that is diverted around the impeller in an umbrella-shaped form.

The material inside the impeller is thrown out at high speed under the action of centrifugal force and collides violently with the impact plate on the top of the crushing chamber. The material breaks along its own weak parts under the strong impact force, achieving primary crushing.

The material rebounded by the impact plate collides with the material thrown out by the impeller again, and also impacts and crushes with the material in the crushing chamber and the impact plate for multiple times, making the material continuously refined.

In the crushing chamber, the material continuously undergoes a cycle of impact, rebound, and re-impact. During this process, the material is continuously crushed until its particle size reaches the required level.

The materials that meet the particle size requirements will be discharged from the discharge port at the bottom of the crusher and become the final crushed products.

*The output will vary according to different materials, feed particle size and other factors

| Model | Feeder Opening Size (mm) | Max. Feeding Size (mm) | Output Adjusting Range (mm) | Motor Power (kw) | Capacity (t/h) |

| CI100 | 700×1140 | 400 | 20-100 | 90-110 | 100-150 |

| CI150 | 820×980 | 500 | 20-100 | 132-160 | 150-200 |

| CI250 | 960×1360 | 600 | 20-100 | 220-250 | 200-280 |

| CI350 | 1050×1700 | 700 | 20-200 | 280-355 | 300-400 |

| CI450 | 1350×1950 | 900 | 20-200 | 355-500 | 400-600 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.