Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

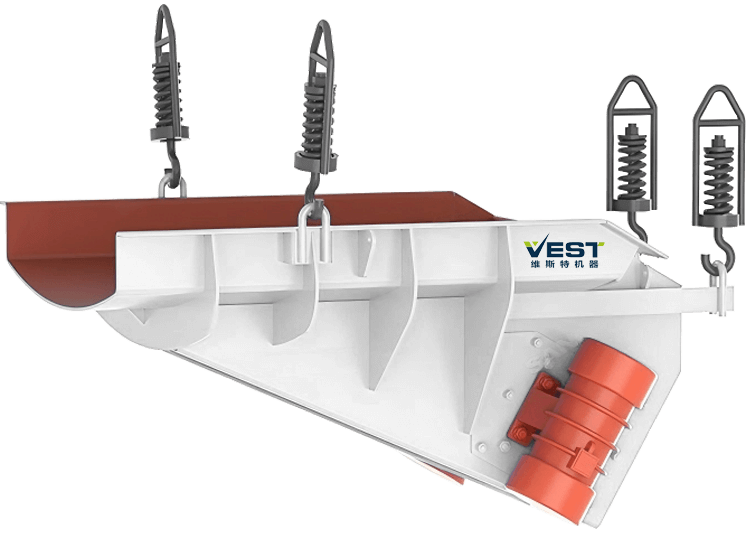

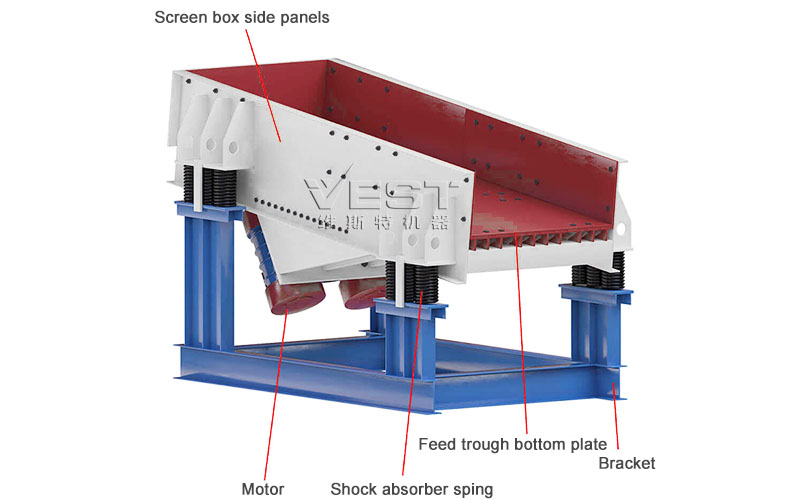

GZG Series Vibrating Feeder is used to convey bulk, grainy and powdery materials continuously and evenly from the stock bin to targeted equipment.

GZG vibrating feeder has the advantages of uniform feeding, convenient adjustment, stable operation, low energy consumption, low noise and strong adaptability to materials.

Simple structure, light, low noise, reliable performance, large feeding capacity, easy maintenance.

It can start quickly, work, and stop steadily since the utilization of the motor synchronization principle.

The material moves in a parabolic path, so the wear of the feeding chute is little.

The flow direction of the material can be changed at any time, so the precision of the material amount is very high.

GZG series vibrating feeder are used for feeding materials into the crushers homogeneously and continuously in the sand stone product line. This equipment is widely used in the fields of metallurgical, coal, mineral processing, building materials, chemical engineering, grinding, etc.

The feeding process of the GZG series feeder is realized by using a special vibration motor or two motors to drive the vibrator to drive the feeding trough to make periodic linear reciprocating vibrations along the inclined direction.

When the vertical component of the acceleration of the feeding trough vibration is greater than the gravity acceleration, the material in the trough is thrown up and jumps forward along the trajectory of the parabola.

The throwing and falling are completed in an instant. Due to the continuous excitation of the excitation source, the feeding trough vibrates continuously, and the coal in the trough jumps forward continuously to achieve the purpose of feeding.

*The output will vary according to different materials, feed particle size and other factors

| Model | Max Feed Siz (mm) | Vibrating Speed (r/min) | Double Amplitude (mm) | Capacity(t/h) | Motor Power (kw) | Size of Funnel (mm) | Overall Dimension (mm) | |

| Horizontal | -10° | |||||||

| GZG40-4 | 100 | 1450 | 4 | 30 | 40 | 2×0.25 | 400×1000×200 | 1337×750×600 |

| GZG50-4 | 150 | 1450 | 4 | 60 | 85 | 2×0.25 | 500×1000×200 | 1374×800×630 |

| GZG63-4 | 200 | 1450 | 4 | 110 | 150 | 2×0.50 | 630×1250×250 | 1648×1000×767 |

| GZG70-4 | 200 | 1450 | 4 | 120 | 170 | 2×0.50 | 700×1290×250 | 1548×1010×787 |

| GZG80-4 | 250 | 1450 | 4 | 160 | 230 | 2×0.75 | 800×1500×250 | 1910×1188×850 |

| GZG90-4 | 250 | 1450 | 4 | 180 | 250 | 2×0.75 | 900×1483×250 | 2003×1178×960 |

| GZG100-4 | 300 | 1450 | 4-6 | 270 | 380 | 2×1.1 | 1000×1750×250 | 2190×1362×900 |

| GZG100-4Z | 350 | 1450 | 4-6 | 270 | 380 | 2×1.5 | 1000×1700×250 | 2165×1716×1068 |

| GZG110-4 | 300 | 1450 | 4-6 | 300 | 420 | 2×1.1 | 1100×1673×250 | 2151×1362×970 |

| GZG110-4Z | 350 | 1450 | 4-6 | 300 | 420 | 2×1.5 | 1100×1700×250 | 2165×1816×1068 |

| GZG125-4 | 350 | 1450 | 4-6 | 460 | 650 | 2×2.25 | 1250×2000×315 | 2540×1500×1030 |

| GZG125-4Z | 350 | 1450 | 4-6 | 460 | 650 | 2×2.25 | 1250×1800×300 | 2273×1970×1176 |

| GZG130-4 | 350 | 1450 | 4-6 | 480 | 670 | 2×2.25 | 1300×2040×300 | 2544×1556×1084 |

| GZG150-6 | 350 | 960 | 4-6 | 520 | 750 | 2×3.0 | 1500×1800×400 | 2250×1864×1412 |

| GZG150-6Z | 350 | 960 | 4-6 | 520 | 750 | 2×3.0 | 1500×1800×400 | 2289×2180×1302 |

| GZG160-6Z | 500 | 1450 | 5-6 | 770 | 1100 | 2×3.2 | 1600×2500×315 | 3050×1850×1110 |

| GZG180-6Z | 500 | 1450 | 5-6 | 900 | 1200 | 2×3.7 | 1800×2325×375 | 2885x2210x1260 |

| GZG200-6Z | 500 | 1450 | 5-6 | 1000 | 1400 | 2×5.5 | 2000×3000×280 | 3490x2400x1220 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.