Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

YGM grinding mill is an advanced version of Raymond grinding mill. It is a high-pressure suspension roller grinding equipment suitable for crushing non-metallic minerals (such as limestone, gypsum, quartz, feldspar, marble, etc.) and chemical raw materials with Mohs hardness ≤ 9.3 and humidity ≤ 6%. The finished product fineness can be adjusted to 30-425 mesh.

YGM grinding mill is a high-pressure suspension roller grinding equipment, which increases the grinding force through the enhanced spring pressure system. It is an upgraded version of Raymond mill. It can efficiently grind non-metallic minerals (such as quartz, feldspar, marble, etc.) with Mohs hardness ≤ 9.3 and humidity ≤ 6%, and the finished product fineness range is 30-425 mesh.

The reinforced spring pressure system is adopted to increase the crushing force by 20-30%, achieving efficient fine crushing of materials with Mohs hardness ≤ 9.3, and the output is increased by 10-15% compared with traditional mills.

The particle size of the finished product can be freely adjusted within the range of 30-425 mesh. The powder fineness can be accurately controlled by adjusting the analyzer speed or air volume to meet diverse production needs.

Equipped with pulse dust collector and noise reduction technology, the dust emission concentration is less than 20mg/m³, and the energy consumption is reduced by 15-20% year-on-year, which meets the green production standards.

Key components (grinding roller, grinding ring) are made of high manganese steel or alloy steel, which extends the service life by 2-3 times, with long maintenance cycle and low operating cost.

YGM grinding mill is mainly used for the processing of non-metallic mineral powders with Mohs hardness ≤ 9.3 (such as limestone, gypsum, quartz, feldspar, marble, etc.), and is widely used in building materials, chemical and metallurgical industries; it is also suitable for ore powder making, power plant desulfurization and ceramic raw material preparation. The finished product fineness is adjustable from 30 to 425 mesh, meeting the needs of high-precision large-scale production.

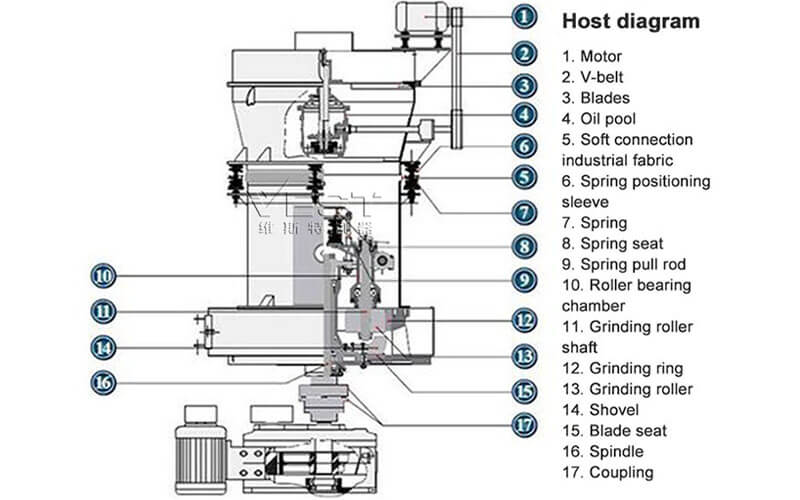

The YGM high-pressure medium-speed mill is fastened with a high-pressure spring with a pressure of 1000-1500 kg on the roller hanger. Under the action of the high-pressure spring and centrifugal force, the roller rotates around the main shaft and rolls close to the grinding ring. Its rolling pressure is 1.2 times higher than that of the Raymond mill, so the output is greatly improved.

When the material to be ground enters the grinding chamber, it is scooped up by the scraper and sent to the grinding roller and grinding ring to roll. The rolling powder is brought into the analyzer with the circulating wind of the fan. Qualified fine powder flows into the cyclone powder collector with the air to become the finished product. The large particles fall back to be re-grinded, and the circulating wind returns to the fan. Repeat the above process, and the remaining air enters the pulse dust collector for purification.

When the grinding roller and the grinding ring reach a certain wear, adjust the length of the high-pressure spring to maintain a constant rolling pressure between the grinding roller and the grinding ring, thereby ensuring stable output and fineness.

*The output will vary according to different materials, feed particle size and other factors

| Model | YGM75 | YGM85 | YGM95 | YGM130 | YGM160 | YGM190 |

| Grinding ring Dia x Height (mm) | φ780×150 | φ830×140 | φ950X170 | φ1280X210 | φ1600X270 | φ1900X320 |

| Roller Number (pcs) | 3 | 3 | 4 | 5 | 6 | 6 |

| Roller Size L x H (mm) | φ260×150 | φ270×140 | φ310X170 | φ430X210 | φ530X270 | φ630X320 |

| Max Input size (mm) | 15 | 20 | 25 | 30 | 35 | 40 |

| Output size (mm) | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 |

| Capacity (t/h) | 1 – 3 | 1.2-4 | 2.1-5.6 | 2.5-9.5 | 8 – 16 | 18-36 |

| Power (kw) | 18.5 | 22 | 37 | 75 | 185 | 250 |

| Overall Dimension (mm) | 4300x3500x5100 | 5300x4100x5200 | 7100x5900x7900 | 7900x8000x9700 | 12550×5700×8355 | 11200x8530x9685 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.