Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

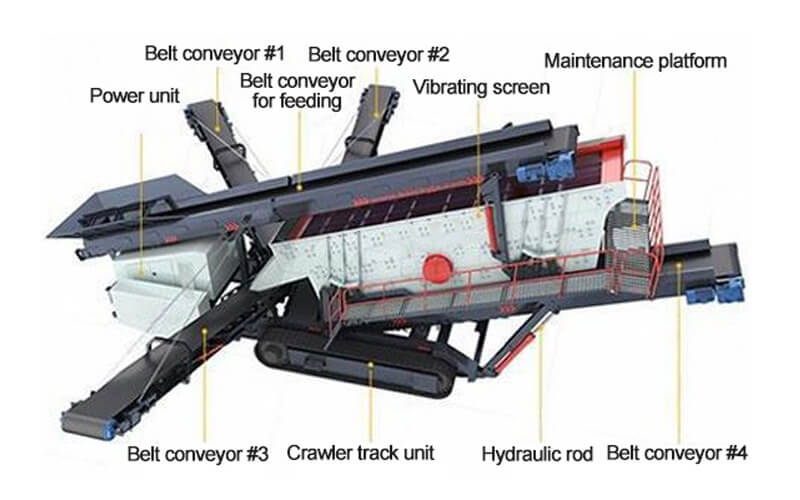

The crawler screening station is a movable screening equipment, which has the advantages of strong mobility and adaptability to the screening of various materials.

The tracked screening plant offers a powerful and flexible solution for efficient material separation and processing. Its combination of advanced screening technology, mobility, and robust construction makes it an essential tool for a wide range of applications in the construction, mining, and recycling industries. With its ease of operation and adaptability, the tracked screening plant provides high performance and operational efficiency in diverse environments.

The tracked chassis provides outstanding mobility and stability, allowing the plant to navigate a variety of terrains, including rough and uneven surfaces, Ideal for urban and remote job sites.

The plant is equipped with a high-performance screening system that efficiently separates materials based on size and type. Advanced vibrating screens or trommels are used to sort materials into various grades and sizes, ensuring that the final product meets specific quality and consistency requirements.

The crawler screening plant is highly adaptable. It is commonly used for sorting aggregates, recycling construction and demolition debris, processing topsoil, and handling various other bulk materials. Its versatility makes it an invaluable asset for diverse industries.

Designed to withstand demanding conditions, the plant features a durable and rugged construction. The tracked chassis is engineered for stability and reliability, while the screening components are built to handle continuous operation with minimal maintenance.

Tracked screening plants can be useful for contractors, in rock mining operations, aggregate producers, road building operations, demolition/recycling companies, and more.

Materials are fed into the crushing plant through a primary feeding system – Belt feeder.

The heart of the crawler screening plant is the YKR vibrating screen. Materials are fed onto a screen mesh that vibrates to facilitate the movement of particles. The mesh has different screen sizes to separate materials into various grades. Finer materials pass through the mesh, while larger particles are retained and moved to the next stage.

The entire screening plant is mounted on a tracked undercarriage, which provides excellent mobility and stability. The tracked system allows the plant to move smoothly across various terrains, including rough and uneven surfaces, and makes it easier to reposition the plant as needed.

*The output will vary according to different materials, feed particle size and other factors

| VTS Tracked Portable Screening Plant | ||||||||

| Model | VTS3712T | VTS4815D | VTS4815T | VTS6018D | VTS6018T | VTS6020D | VTS6020T | VTS6024T |

| Plant Power (kw) | 31.7+37.5 | 39.5+45 | 45.7+45 | 48.5+45 | 54.7+75 | 52.5+75 | 58.7+75 | 73.7+75 |

| Capacity (t/h) | 30-120 | 100-300 | 100-300 | 150-350 | 150-350 | 200-400 | 200-400 | 250-450 |

| Weight (t) | 25 | 28 | 32 | 33 | 36 | 35 | 38 | 42 |

| Sizes L×W×H (mm) | 13000×2900×3400 | 14000×3200×3400 | 14000×3200×3600 | 15500×3400×3600 | 15500×3400×3800 | 15500×3600×3600 | 15500×3600×3800 | 15500×3900×3900 |

| Belt Feeder | ||||||||

| Volume (m3) | 3 | 3.5 | 3.5 | 4 | 4 | 4 | 4 | 5 |

| Size (mm) | 800×9000 | 1000×11000 | 1000×11000 | 1000×15000 | 1000×15000 | 1000×15000 | 1000×15000 | 1200×15000 |

| Power (kw) | 5.5 | 11 | 11 | 11 | 11 | 15 | 15 | 22 |

| Vibrating Screen | ||||||||

| Model | 3YKS1237 | 2YKS1548 | 3YKS1548 | 2YKS1860 | 3YKS1860 | 2YKS2160 | 3YKS2160 | 3YKS2460 |

| Power (kw) | 11 | 15 | 15 | 22 | 22 | 22 | 22 | 30 |

| The 1st Layer Discharge Belt | ||||||||

| Size (mm) | B500×5500 | B500×6500 | B500×6500 | B500×6500 | B500×6500 | B650-7500 | B650-7500 | B650-7500 |

| Discharge Height (mm) | 2600 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 |

| Power (kw) | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| The 2nd Layer Discharge Belt | ||||||||

| Size (mm) | B500×6500 | B500×7500 | B500×7500 | B500×7500 | B500×7500 | B650×7500 | B650×7500 | B650×7500 |

| Discharge Height (mm) | 2600 | 3200 | 3200 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Power (kw) | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| The 3rd Layer Discharge Belt | ||||||||

| Size (mm) | B500×6500 | ———— | B500×7500 | ———— | B500×7500 | ———— | B650×7500 | B650×7500 |

| Discharge Height (mm) | 2600 | ———— | 3200 | ———— | 3200 | ———— | 3200 | 3200 |

| Power (kw) | 3 | ———— | 4 | ———— | 4 | ———— | 4 | 4 |

| Transfer Belt | ||||||||

| Size (mm) | B500×2500 | ———— | B500×2500 | ———— | B500×2800 | ———— | B650×2800 | B650×2800 |

| Discharge Height (mm) | 2000 | ———— | 2200 | ———— | 2200 | ———— | 2200 | 2200 |

| Power (kw) | 2.2 | ———— | 2.2 | ———— | 2.2 | ———— | 2.2 | 2.2 |

| Under-Screen Belt | ||||||||

| Size (mm) | B800×6500 | B800×8500 | B800×8500 | B1000×10000 | B1000×10000 | B1000×10000 | B1000×10000 | B1200×10000 |

| Discharge Height (mm) | 2800 | 3200 | 3200 | 3700 | 3700 | 3700 | 3700 | 3700 |

| Power (kw) | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Dual-power Assembly | ||||||||

| Driving Mode | Diesel — electricity | |||||||

| Note: Product models, parameters, appearance, etc. are constantly being improved. If any modifications cause differences please refer to the actual product received. | ||||||||

Have Any Questions!

Don't Hesitate To Contact Us Anytime.