Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Bucket elevator is mainly used to convey various bulk materials and is an indispensable equipment in the entire grinding production line.

Bucket elevators are used to vertically lift various bulk materials. Their advantages are large lifting height, large conveying capacity, stable and reliable operation, and effective prevention of material spillage.

The floor area is small, the transmission speed can be adjusted according to the transmission volume, and the lifting height can be selected as needed.

Good sealing, less environmental pollution.

Easy to operate, less maintenance, and fewer wearing parts; due to low energy consumption and less maintenance, the use cost is low.

The feeding of the elevator adopts the flow-in type, so there is little squeezing and collision between materials. The design of this machine ensures that the material is rarely scattered during feeding and unloading, reducing mechanical wear.

A bucket elevator, also known as a bucket lift or bucket conveyor, is a type of vertical transport equipment used to move bulk materials from one level to another. It is commonly used in industries such as agriculture, mining, and manufacturing.

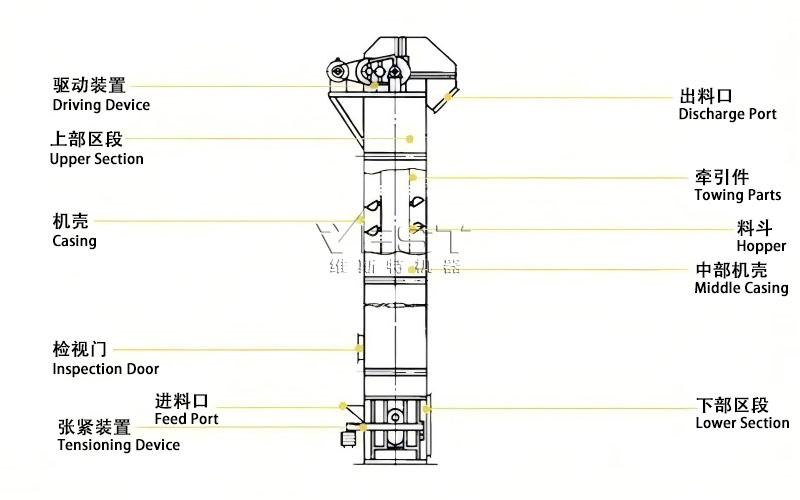

Material is fed into the buckets at the bottom of the elevator.

As the belt or chain moves, the buckets travel upwards. Once at the top, the buckets are tipped or emptied, discharging the material into a chute or another container.

The empty buckets then return to the bottom of the elevator to pick up more material.

*The output will vary according to different materials, feed particle size and other factors

| Model | Bucket Width(mm) | Bucket Distance(mm) | Speed(m/s) | Max Granule size(mm) | Capacity (t/h) |

|---|---|---|---|---|---|

| T160 | 160 | 300 | 1.4 | 25 | H+0.9 |

| T250 | 250 | 420 | 1.6 | 35 | H+1.2 |

| T315 | 315 | 500 | 1.6 | 45 | H+1.2 |

| T400 | 400 | 560 | 1.8 | 55 | H+1.5 |

| T500 | 500 | 625 | 1.8 | 60 | H+1.5 |

Have Any Questions!

Don't Hesitate To Contact Us Anytime.