Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

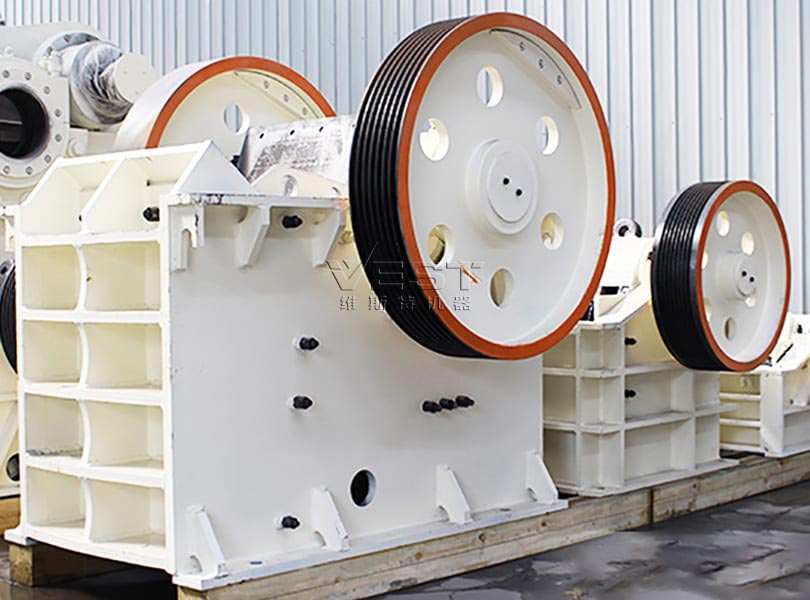

PE Jaw crusher is one traditional primary or secondary crushing equipment used to crush stone below 320MPa compressive strength. It will crush Large stone to Medium or small size (crushing ratio 3-6), which have various models to meet a lots of capacity requirements of crushing plants.

The PE series jaw crusher is a staple in the world of material processing, renowned for its reliability and efficiency in primary crushing operations. It's designed to handle a wide range of materials, making it an essential tool in various industries. It will crush Large stone below 320MPA compressive strength to Medium or small size, which have various models to meet a lots of capacity requirements of crushing plants. PE series jaw crusher offers a combination of durability, high - efficiency, ease of use, and versatility.

The PE series jaw crusher features a sturdy and durable structure. The main frame is typically made of high - quality cast steel, which can withstand the intense impact and stress during the crushing process. This robust construction not only ensures a long service life but also reduces the need for frequent maintenance, minimizing downtime and increasing productivity.

With a high crushing ratio, this crusher can effectively break down large - sized materials into smaller particles in a single pass. It can handle materials with a compressive strength of up to 350 Mpa, making it suitable for crushing various hard and soft ores, such as granite, basalt, and limestone. The large feed opening allows for the processing of relatively large - sized raw materials, and the adjustable discharge opening enables you to control the output particle size according to your specific requirements.

One of the key advantages of the PE series jaw crusher is its simplicity in operation. The straightforward design makes it easy for operators to learn and use, reducing the need for extensive training. In terms of maintenance, the accessible components and simple structure facilitate quick and hassle - free repairs. The lubrication system is designed to ensure smooth operation of moving parts, and the wear - resistant materials used in critical components, such as the jaw plates, extend their service life, further reducing maintenance costs.

This crusher has found wide applications in numerous industries, including mining, construction, and road building. In the mining industry, it is used as the primary crusher to break down large ore chunks into smaller sizes for further processing. In the construction and road building sectors, it can crush stones and rocks to produce aggregates of the right size for use in concrete production and road base construction. Its versatility makes it a popular choice for businesses looking for a reliable and multi - purpose crushing solution.

PE jaw crusher can effectively handle materials with a compressive strength of up to 350 MPA with a crushing ratio 3-6. This includes various hard and soft ores, including limestone, river pebbles, granite, basalt, iron ore, quartz, shale, sandstone, etc. It’s widely used in mining industry, construction industry (aggregates of specific sizes for various construction projects, concrete making), quarrying Industry, recycling Industry (concrete, bricks, and asphalt breaking, recycling these materials into reusable aggregates) etc.

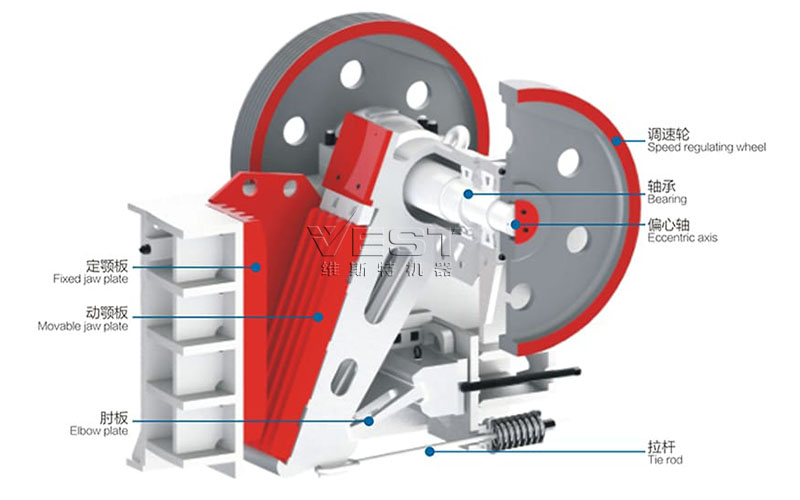

The crushing method of PE series jaw crusher is the cam-type extrusion type.

The motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to approach the fixed jaw plate.

At the same time, the material is squeezed, rubbed, and crushed in multiple ways; when the movable jaw descends, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring.

The crushed material is discharged from the lower opening of the crushing chamber. As the motor rotates continuously, the movable jaw of the crusher performs periodic crushing and discharging to achieve mass production.

*The output will vary according to different materials, feed particle size and other factors

| Model | Size of Feed Opening (mm) | Max Feed Edge (mm) | Discharge Opening Range(mm) | Eccentric Shaft Speed (r/min) | Capacity (t/h) | Motor Power (kw) |

| PE250×400 | 250×400 | 220 | 20-60 | 300 | 5-20 | 15 |

| PE400×600 | 400×600 | 340 | 40-100 | 275 | 15-60 | 30 |

| PE500×750 | 500×750 | 425 | 50-100 | 275 | 40-110 | 45-55 |

| PE600×900 | 600×900 | 500 | 65-160 | 250 | 90-180 | 75 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 250 | 110-320 | 110 |

| PE900×1200 | 900×1200 | 720 | 95-165 | 200 | 220-450 | 132-160 |

| PE1000×1200 | 1000×1200 | 800 | 200-300 | 200 | 280-560 | 160-185 |

| PE1200×1500 | 1200×1500 | 1000 | 150-300 | 180 | 400-800 | 200-220 |

| PE1500×1800 | 1500×1800 | 1200 | 210-360 | 180 | 700-1280 | 355-400 |

| Model | Size of Feed Opening (mm) | Max Feed Edge (mm) | Discharge Opening Range (mm) | Eccentric Shaft Speed (r/min) | Capacity (t/h) | Motor Power (kw) |

| PEX250×750 | 250×750 | 210 | 25-60 | 330 | 13-35 | 30 |

| PEX250×1000 | 250×1000 | 210 | 25-60 | 330 | 16-55 | 30 |

| PEX250×1200 | 250×1200 | 210 | 25-60 | 330 | 20-60 | 37 |

| PEX300×1300 | 300×1300 | 250 | 20-90 | 300 | 30-90 | 55-75 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.