Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

HGM ultra-fine grinding mill is suitable for non-metallic minerals with Mohs hardness below 6 (such as calcite, barite, talc, etc.), with an hourly output of 0.5-25 tons per machine. It is widely used in ultrafine powder processing (80-2500 mesh) in the fields of chemical industry, building materials, coatings, ceramics, etc.

HGM ultrafine grinding mill is suitable for non-metallic minerals (such as talc, bentonite, kaolin, etc.) and chemical raw materials with Mohs hardness ≤ 6. It can realize the processing of ultrafine powders of micron level (80-2500 mesh) and is widely used in coatings, medicine, new materials and other fields.

The finished product fineness covers 80-2500 mesh (1μm~20μm), which can be precisely controlled through the grading system to meet the processing needs of micron-level ultrafine powders.

The multi-layer grinding roller and optimized ring design ensure uniform grinding pressure distribution and increase production capacity by 20-30%, especially suitable for brittle materials with Mohs hardness ≤ 6.

Equipped with pulse dust removal and negative pressure operation technology, the dust emission concentration is less than 10mg/m³, and the comprehensive energy consumption is reduced by 20-30% compared with traditional equipment, meeting strict environmental protection standards.

The integrated PLC control system and remote monitoring function realizes the full process automation management of feeding, grinding and grading, which is convenient to operate and highly stable.

HGM micro-powder grinding mill is mainly used for ultrafine powder processing of non-metallic minerals (such as talc, kaolin, bentonite, etc.) and chemical raw materials with Mohs hardness ≤ 6, and is widely used in coatings, ceramics, medicine and other industries; it is also suitable for micronization of food additives, cosmetic raw materials and industrial solid waste, and the finished product fineness reaches 80-2500 mesh.

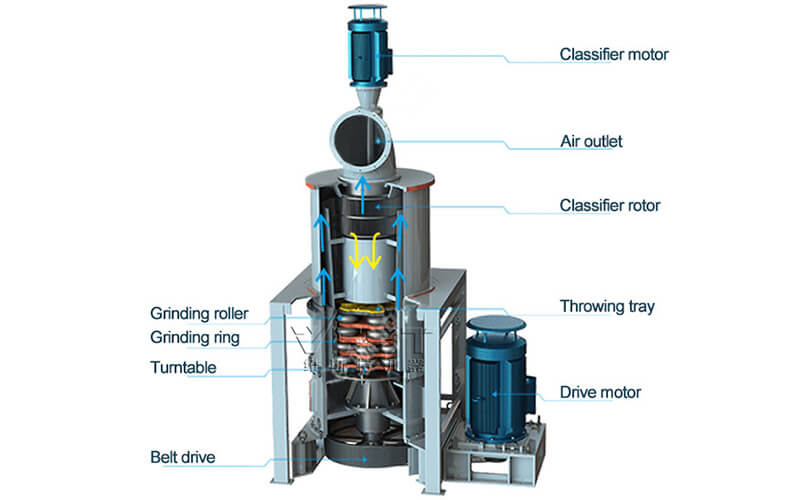

When the HGM grinding mill is working, the main motor drives the main shaft and the turntable to rotate through the reducer, and the roller pins on the edge of the turntable drive dozens of grinding rollers to roll in the grinding ring raceway. Large materials are scattered to the periphery under the action of centrifugal force and fall into the grinding ring raceway to be impacted, rolled, and ground by the ring rollers. After being processed by the three-layer ring raceway, they become powder.

The high-pressure fan sucks the external air into the machine through suction and brings the crushed materials into the powder selector. The rotating impeller in the powder selector makes the coarse materials fall back to be re-grinded, and the fine powder that meets the requirements enters the cyclone powder collector with the airflow and is discharged from the discharge valve at the bottom as the finished product, while the airflow with a small amount of fine dust is purified by the pulse dust collector and discharged through the fan and muffler.

*The output will vary according to different materials, feed particle size and other factors

| Model | HGM80 | HGM100 | HGM125 | HGM168 | |

| Qty of Rollers (pcs) | 21 | 36 | 40-44 | 30-40 | |

| Qty of Ring (pcs) | 3 | 4 | 4 | 4 | |

| Average Dia (mm) | 800 | 1000 | 1250 | 1680 | |

| Feeding size (mm) | <20 | ||||

| Output size (mm) | Micron | 106-4 | |||

| Mesh | 150-3000 | ||||

| Capacity (kg/h) | 500-5000 | 1000-8500 | 1500-12000 | 5000-25000 | |

| Power (kw) | 55 | 110 | 160 | 315 | |

| Overall Dimension Lx W x H (m) | 13.9x4x6.2 | 18x4.6x8.6 | 14x9x10.25 | 26.3x7.5x11.9 | |

Note: Capacity will vary if project requests have different factors, such as stone type, discharging size, gravity ect.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.