Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

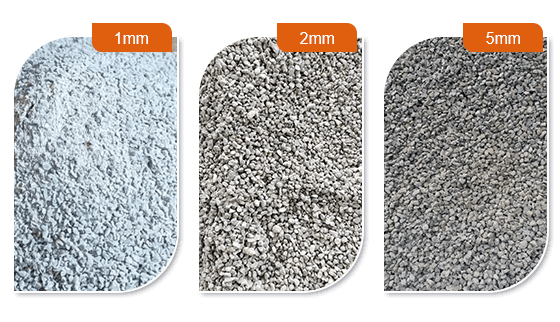

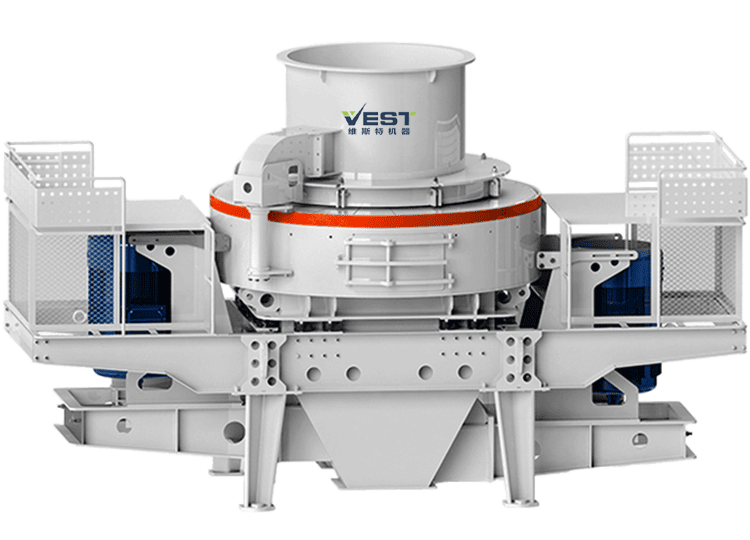

VSI impact crusher can crush granite, basalt and other medium to high hardness stones with high processing capacity and output of 50 - 580 t/h. The output particle size is uniform and can be precisely controlled within the range of 0-5 mm. It has the advantages of high sand making efficiency, good particle shape, low energy consumption and durable equipment.

VSI impact sand making machine is a highly efficient sand making equipment with the advantages of high sand making efficiency, good particle shape and low energy consumption. It is widely used in construction sand, stone shaping and ore crushing.

The unique impeller structure and high-speed operation cause the material to impact and break at high speed, greatly increasing the amount of sand produced per unit time.

The material is impacted and shaped multiple times in the equipment, and the finished sand particles are round, mostly cubic, and have uniform particle size.

Advanced design makes energy utilization more reasonable, reduces electricity consumption and saves costs while making sand efficiently.

Key components are made of highly wear-resistant materials and have a stable structure, which can adapt to high-intensity work and reduce fault maintenance.

VSI impact sand making machine is suitable for crushing medium to high hardness stones, such as granite, basalt, quartz stone, river pebbles, etc. It is widely used in the production of machine-made sand in the construction industry, the preparation of sand and gravel for water conservancy and hydropower projects, and the fine crushing and shaping of various ores.

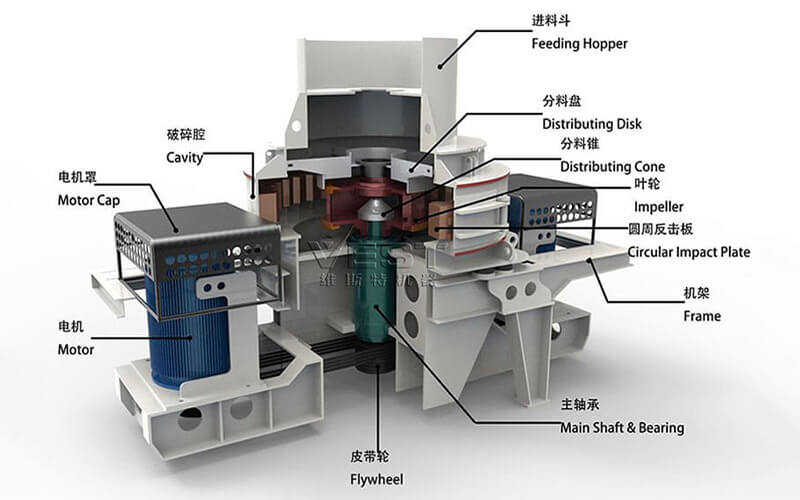

Center Feeding:

Raw material falls into the feed hopper and then enters the impellor through the central entrance hole. It is accelerated in a high-speed impellor and then thrown out at speeds of 60-75 m/s. When hitting an impact plate, it is crushed. Final products come downwards through outlets.

Ring Feeding:

Raw material falls into the feed hopper, then, through a ring, it is divided into two parts by the material-dividing plate. One enters the impellor through the center of the material-dividing plate. The other falls from outside of the material-dividing plate. Material, which is thrown out by the impellor at a speed of 60-75 m/s, hits material coming down from outside of the material-dividing plate. In this way, the material is crushed.

*The output will vary according to different materials, feed particle size and other factors

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | |

| Capacity(t/h) | Cascade and Center Feeding | 120-180 | 200-260 | 300-360 | 450-520 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Feeder Opening Size(mm) | Soft Material | <35 | <40 | <45 | <50 |

| Hard Material | <30 | <35 | <40 | <45 | |

| Rotation Speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Power of the Double Motors(kw) | 2×55 | 2×90 | 2×132 | 2×200 | |

| Overall Dimension LxWxH(mm) | 3700×2150×2100 | 4140×2280×2425 | 1564×2447×2778 | 500×2700×3300 | |

| Vibrating Sensor | 0.1-20mm/s Inspection Scope: 0.1-20mm/s, it canbe a djustde continuously | ||||

| Hydraulic Lubrication Station | Power of Double Oil Pump(kw) | 2×0.31 | |||

| Safety | Double oil pumps make sure supply of oil with; Stop automatically; Heating start the motorin winter | ||||

| Overall Dimension(mm) | 820×520×1270 | ||||

| Power of Oil-Box Heater(kw) | 2 | ||||

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.