Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Single-cylinder hydraulic cone crusher is an advanced rock crushing equipment, it has the advantages of simple structure, small footprint, high crushing efficiency, uniform product size, etc., it is widely used in mining, construction and other industries.

CS/CH Single cylinder Hydraulic Cone Crusher is a medium and fine crushing equipment using advanced hydraulic technology. It is widely used in mining, building materials, metallurgy and other fields. It is suitable for crushing ores and rocks with medium and above hardness (such as granite, basalt, iron ore, etc.). Its core design features a single-cylinder hydraulic system that integrates efficient crushing, intelligent control and stable operation.

Laminated crushing principle: the material is crushed in multiple layers of extrusion, the particle shape is better (high cube ratio), the needle-like shape is reduced, and the finished product is suitable for high-end aggregate needs.

Large eccentricity and high swing frequency: optimize motion parameters, improve processing capabilities, and reduce unit energy consumption.

The hydraulic system integrates discharge port adjustment, overload protection and cavity clearing functions. The operation is completed with one button on the electronic control panel and supports remote monitoring.

Monitor spindle position and hydraulic pressure in real time and automatically optimize operating status.

The single-cylinder design replaces the traditional multi-cylinder structure, reducing hydraulic pipelines and sealing points, and reducing the failure rate.

The main shaft and the moving cone are supported as a whole, which enhances the rigidity. The key components (such as the liner) adopt the quick-release design, which shortens the replacement time by more than 50%.

Key components (spindle, frame) are cast from high-strength alloy steel with strong fatigue resistance.

The thin oil lubrication system has independent circulation, equipped with multi-stage filtration and temperature control alarm to ensure the life of the bearing.

In mining, single-cylinder hydraulic cone crusher can perform coarse, medium and fine crushing on ores of various hardnesses, providing raw materials of suitable particle size for subsequent mineral processing operations; in the field of construction aggregate production, it can efficiently produce stones with uniform particle size and good shape to meet the material needs of roads, bridges, buildings and other projects.

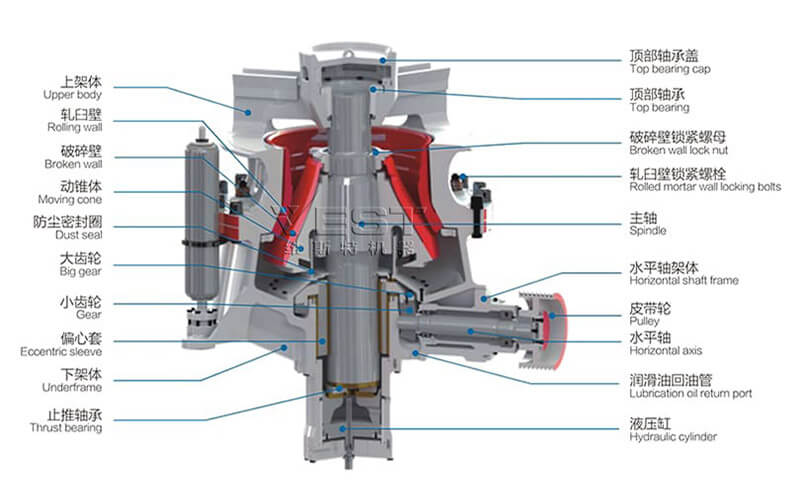

When the single-cylinder hydraulic cone crusher is working, the motor drives the transmission shaft to drive the eccentric sleeve to rotate, so that the crushing wall on the main shaft makes a rotary pendulum motion, forming a periodic distance change with the mortar wall.

The material is crushed by the extrusion force between the two, and the crushed material is discharged from the discharge port by gravity.

At the same time, the single-cylinder hydraulic system can adjust the size of the discharge port, and can also protect the equipment when encountering unbreakable objects, and automatically reset after the foreign objects are discharged.

*The output will vary according to different materials, feed particle size and other factors

| Model | Cavity Type | Max Feed Edge (mm) | Capacity at CSS (Close side setting) (t/h) | Power(kw) | Capacity(t/h) | ||||||||

| 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 44mm | 51mm | 54mm | |||||

| CS - Medium Crushing | |||||||||||||

| CS420 | Extra Coarse (EC) | 240 | / | 80-90 | 85-100 | 90-130 | 105-195 | 120-170 | / | / | / | 90 | 70-170 |

| Coarse (C) | 200 | 65-75 | 70-80 | 75-110 | 80-145 | 95-130 | / | / | / | / | |||

| CS430 | Extra Coarse (EC) | 360 | / | / | 115-135 | 125-145 | 145-265 | 165-355 | 185-395 | 205-295 | 215-245 | 160 | 90-330 |

| Coarse (C) | 300 | / | 100-115 | 110-155 | 115-165 | 135-290 | 150-330 | 170-305 | / | / | |||

| CS440 | Extra Coarse (EC) | 450 | / | 235-270 | 250-290 | 315-540 | 350-600 | 365-525 | / | / | / | 250 | 190-610 |

| Coarse (C) | 400 | 205-235 | 225-325 | 240-345 | 300-515 | 335-385 | / | / | / | / | |||

| CS660 | Extra Coarse (EC) | 560 | / | / | 295-340 | 370-635 | 410-825 | 430-985 | 490-1125 | 525-1210 | 560-1130 | 315 | 310-1020 |

| Coarse (C) | 500 | / | 265-305 | 285-405 | 355-710 | 392-905 | 410-945 | 470-945 | 505-725 | ||||

| CH - Fine Crushing | |||||||||||||

| CH420 | Coarse (EC) | 130 | / | / | 45-55 | 50-100 | 55-105 | 60-115 | 75-145 | / | / | 90 | 30-150 |

| Coarse (C) | 90 | / | / | 45-60 | 45-105 | 50-110 | 55-120 | 70-80 | / | / | |||

| Medium (M) | 64 | / | 35-50 | 40-85 | 40-90 | 45-90 | 50-70 | / | / | / | |||

| Medium Fine(MF) | 48 | 35-40 | 40-75 | 40-80 | 45-80 | 45-60 | / | / | / | / | |||

| Fine (F) | 38 | 30-60 | 30-60 | 36-85 | 35-55 | 40-55 | / | / | / | / | |||

| Extra Fine (EF) | 18 | 30-40(80% finess is less than 4.5-5.5mm) | |||||||||||

| CH430 | Extra Coarse (EC) | 190 | / | / | 70-125 | 75-170 | 80-185 | 105-240 | 115-240 | / | 160 | 50-250 | |

| Coarse (C) | 145 | / | / | 70-85 | 65-150 | 70-165 | 75-175 | 100-225 | 110-170 | / | |||

Midium Coarse (MC) | 115 | / | / | 55-65 | 60-160 | 65-175 | 70-185 | 95-165 | / | / | |||

| Medium (M) | 90 | / | 60-75 | 65-100 | 70-150 | 75-165 | 80-175 | 105-120 | / | / | |||

| Medium Fine(MF) | 65 | / | 60-70 | 65-120 | 70-130 | 75-145 | 80-145 | / | / | / | |||

| Fine (F) | 50 | 50-90 | 50-95 | 55-100 | 60-110 | 65-120 | 70-120 | / | / | / | |||

| Extra Fine (EF) | 26 | 70-90(80% finess is less than 5-5.6mm) | |||||||||||

| CH440 | Extra Coarse (EC) | 210 | / | / | / | / | 115-230 | 120-315 | 160-410 | 175-455 | / | 250 | 70-450 |

| Coarse (C) | 170 | / | / | / | 100-115 | 110-250 | 115-335 | 150-435 | 165-385 | / | |||

Midium Coarse (MC) | 140 | / | / | / | 95-140 | 105-300 | 115-325 | 145-380 | 160-280 | / | |||

| Medium (M) | 105 | / | / | / | 115-215 | 125-320 | 135-345 | 175-325 | 195-225 | / | |||

| Medium Fine(MF) | 80 | / | / | 115-130 | 125-260 | 135-280 | 145-300 | 185-285 | / | / | |||

| Fine (F) | 65 | 80-95 | 90-155 | 95-200 | 105-220 | 110-235 | 120-255 | 155-240 | / | / | |||

| Extra Fine (EF) | 35 | 100-125(80% finess is less than 6-7.5mm) | |||||||||||

| CH660 | Extra Coarse (EC) | 300 | / | / | / | / | 175-205 | 190-390 | 235-630 | 270-695 | 330-585 | 315 | 150-700 |

| Coarse (C) | 210 | / | / | / | / | 170-220 | 185-425 | 240-670 | 265-740 | 315-405 | |||

| Midium Coarse (MC) | 170 | / | / | / | / | 160-290 | 175-490 | 225-635 | 250-575 | / | |||

| Medium (M) | 130 | / | / | / | 180-220 | 195-340 | 210-505 | 275-575 | 300-465 | / | |||

| Medium Fine(MF) | 100 | / | / | / | 190-220 | 205-425 | 220-455 | 285-520 | 320-415 | / | |||

| Fine (F) | 75 | / | / | 165-260 | 195-350 | 210-375 | 225-405 | 290-460 | 325-370 | / | |||

| Extra Fine (EF) | 55 | / | / | 150-180 | 210-335 | 225-365 | 245-345 | / | / | / | |||

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.