Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

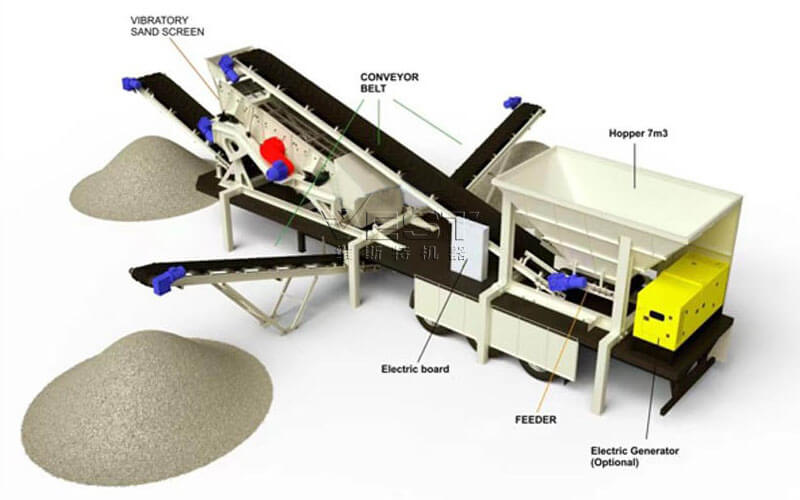

Mobile screening plant is an advanced rock-crushing equipment that can sieve the material to different size range for different purpose, such as construction. It consists of three system: feeding, screening, and conveying.

Tyre mobile screening plant encompasses a belt conveyor above the screen, screening equipment, discharging belt conveyors, frame, and control cabinet, and can be equipped with a grid hopper and hydraulic legs. YKR vibrating screen is the main screening machine with high performance and quality.

It can be quickly assembled into the required mobile station model, thus shortening the production time.

All parts are vehicle-mounted; there is no need to dismantle parts for transportation, which is convenient for on-site installation. All-vehicle belt conveyor crushing plant, and there is no need for cranes and belt supports. With the adjustable landing leg, the foundation-ffree installation is practically realized.

The vibrating screen is self-lubricated by thin oil, which effectively saves labor costs and improves safe operation efficiency to ensure continuous production.

The new onboard integrated intelligent automatic control system makes the operation, maintenance, and adjustment of the crushing operation process more convenient and accurate.

Tire mobile screening stations can be widely used in the field of construction waste treatment. They can efficiently separate construction waste of different particle sizes and realize resource recycling and reuse. At the same time, they also play an important role in the mining industry. They can screen ores on site to improve mining efficiency and ore quality

The material to be screened is fed into the plant through a vibrating feeder or hopper. This ensures an even and controlled flow of material onto the screening decks.

The material moves across the screening decks, which are equipped with mesh screens or perforated plates. As the material travels over the screens, smaller particles pass through the mesh openings, while larger particles remain on the surface.

The screened material is then conveyed to different discharge points based on size. Fine particles may be collected separately from coarse particles, and each size fraction is typically stockpiled or transported for further use or processing.

In recycling applications, the plant efficiently sorts materials like concrete and asphalt, allowing for the reuse of valuable resources and reducing waste.

*The output will vary according to different materials, feed particle size and other factors

| VK Portable Screen Plant | |||||

| Model | VK150S-3 | VK200s-2 | VK200S-3 | VK300S-3 | VK400S-3 |

| Plant Power(kw) | 71.5 | 66 | 71.5 | 71.5 | 83 |

| Capacity(t/h) | 60-250 | 70-350 | 70-350 | 70-450 | 70-550 |

| Vibrating Screen | |||||

| Model | 3YKR1560 | 2YKR1860 | 3YKR1860 | 3YKR2160 | 3YKR2460 |

| Max.feeding size(mm) | 250 | 300 | 300 | 350 | 350 |

| Screen mesh size(mm) | 1500×6000 | 1800×6000 | 1800×6000 | 2100×6000 | 2400×6000 |

| Power (kw) | 22 | 22 | 22 | 22 | 30 |

| Belt Conveyor | |||||

| Feeder Belt (mm) | B1000 | B1000 | B1000 | B1000 | B1200 |

| Under-Screen Belt(mm) | B1000 | B1200 | B1200 | B1200 | B1400 |

| Output Belt(mm) | B650 | B650 | B650 | B650 | B650 |

| Under-Screen Belt Output Height (mm) | 4600 | 4600 | 4600 | 4600 | 4600 |

| Side Belt Output Height (mm) | 5138 | / | 5138 | 5138 | 5138 |

| Output Height (mm) | 3690 | 3690 | 3690 | 3690 | 3690 |

| Note: Product models, parameters, appearance, etc. are constantly being improved. If any modifications cause differences please refer to the actual product received. | |||||

Have Any Questions!

Don't Hesitate To Contact Us Anytime.