Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

The Multi-cylinder Hydraulic Cone Crusher feed size is generally around 50-300 mm, and the output is between 45-600 tons/hour depending on the model. It is widely used in stone crushing operations in mining, construction, roads, railways and other fields.

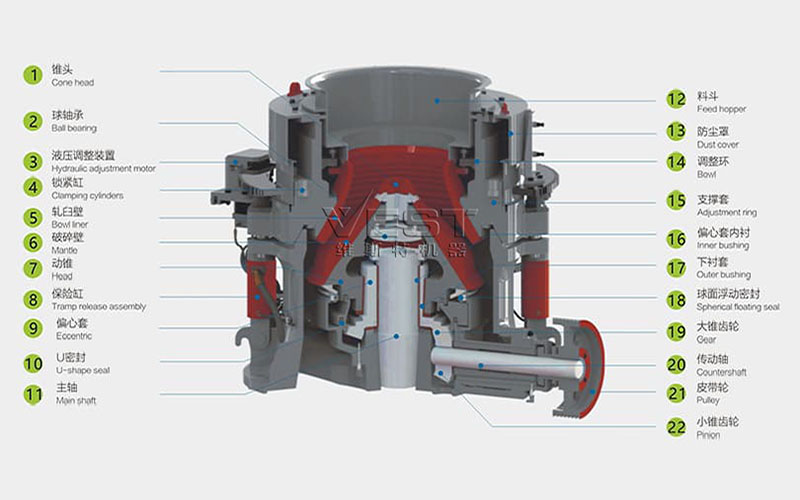

HP Multi-cylinder Hydraulic Cone Crusher is a highly efficient crushing equipment. It uses a multi-cylinder hydraulic system to accurately control the crushing process. The eccentric sleeve drives the crushing wall to squeeze the material toward the mortar wall to achieve crushing. It has the advantages of large crushing ratio, high production efficiency, uniform product particle size, strong equipment stability and easy maintenance.

Large eccentricity and high speed: The fixed axis design of the main shaft allows for larger eccentricity and higher speed, which, together with the optimized cavity shape, significantly improves the processing capacity and crushing ratio.

A variety of cavity types are available: it supports different cavity configurations such as standard type and short head type to meet the needs of coarse crushing, medium crushing and fine crushing, and reduces the types of spare parts on site.

Overload protection and automatic reset: When foreign matter (such as iron blocks) enters the crushing chamber, the hydraulic system drives the moving cone to retreat, and automatically resets after the foreign matter is discharged, avoiding downtime losses.

Intelligent adjustment: The hydraulic motor drives the adjustment sleeve to accurately control the discharge port in real time to ensure stable discharge particle size.

High-strength spindle and wear-resistant lining: The spindle adopts a fixed design, which makes the force more even; the lining is thickened and made of high-strength material to extend the service life.

Sealing and lubrication system: The labyrinth sealing structure prevents dust intrusion, and the lubrication system independently monitors oil temperature and oil volume to reduce maintenance frequency.

Modular design: The fixed cone assembly can be quickly disassembled (e.g. within 10 minutes), which simplifies the workload of liner replacement and reduces downtime.

Simplified steel frame foundation: The whole machine has a compact structure, which reduces installation complexity and reduces the impact on the foundation.

HP Multi-cylinder Hydraulic Cone Crusher is a medium and fine crushing mining crushing equipment using multi-cylinder hydraulic technology. It is mainly used for efficient crushing of hard materials such as ores and rocks. It is widely used in mining, metallurgy, construction and other fields, especially for crushing high-hardness ores (such as granite, limestone, etc.), and can meet the diverse needs of different users for material crushing.

When the HP Multi-cylinder Hydraulic Cone Crusher is working, the motor drives the eccentric sleeve to rotate through the pulley and the transmission shaft, so that the crushing wall moves toward the mortar wall to squeeze the material. The material is crushed by the extrusion, bending and shearing forces in the crushing chamber.

At the same time, the multi-cylinder hydraulic system can automatically adjust the size of the discharge port according to the properties of the material and the crushing requirements to ensure the uniformity of the product particle size.

In addition, when the crusher encounters uncrushable objects, the hydraulic system will automatically release to protect the equipment from damage. The crushed materials are discharged from the discharge port under the action of gravity.

*The output will vary according to different materials, feed particle size and other factors

| Model | Cavity Type | Standard Head | Short Head | Motor Power(kw) | Capacity (t/h) | ||

| Feeder Opening Size(mm) | Output Setting Size(mm) | Feeder Opening Size (mm) | Output Setting Size(mm) | ||||

| HP200 | Coarse (C) | 185 | 19 | 76 | 10 | 132-200 | 90-250 |

| Medium (M) | 125 | 17 | 54 | 6 | |||

| Fine (F) | 95 | 13 | 23 | 6 | |||

| HP300 | Extra Coarse (EC) | 230 | 25 | / | / | 180-250 | 110-440 |

| Coarse (C) | 210 | 20 | 75 | 10 | |||

| Medium (M) | 150 | 15 | 50 | 8 | |||

| Fine (F) | 105 | 10 | 20 | 6 | |||

| HP400 | Extra Coarse (EC) | 295 | 30 | / | / | 280-355 | 140-630 |

| Coarse (C) | 250 | 25 | 90 | 10 | |||

| Medium (M) | 195 | 20 | 50 | 8 | |||

| Fine (F) | 110 | 14 | 40 | 6 | |||

| HP500 | Extra Coarse (EC) | 330 | 30 | / | / | 355-450 | 175-790 |

| Coarse (C) | 285 | 25 | 90 | 13 | |||

| Medium (M) | 200 | 20 | 55 | 10 | |||

| Fine (F) | 133 | 16 | 40 | 8 | |||

| HP800 | Extra Coarse (EC) | 353 | 32 | / | / | 550-630 | 260-1200 |

| Coarse (C) | 297 | 32 | 155 | 13 | |||

| Medium (M) | 267 | 25 | 92 | 10 | |||

| Fine (F) | 219 | 16 | 33 | 6 | |||

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.