Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

PFW impact crusher is suitable for crushing materials with medium and low hardness, such as limestone, dolomite, shale, etc., with an hourly output of 20-1000 tons. It has the characteristics of large crushing ratio and low energy consumption. It can crush various ores and rocks into required particle size. It is widely used in mining, construction, highway and other industries.

PFW impact crusher is suitable for crushing materials with medium and low hardness, such as limestone, dolomite, shale, etc., with an hourly output of 20-1000 tons. It is widely used in mining, construction, highway and other industries. It can break materials through impact energy. The product has good particle shape and is cubic, which can effectively improve the quality of the finished product.

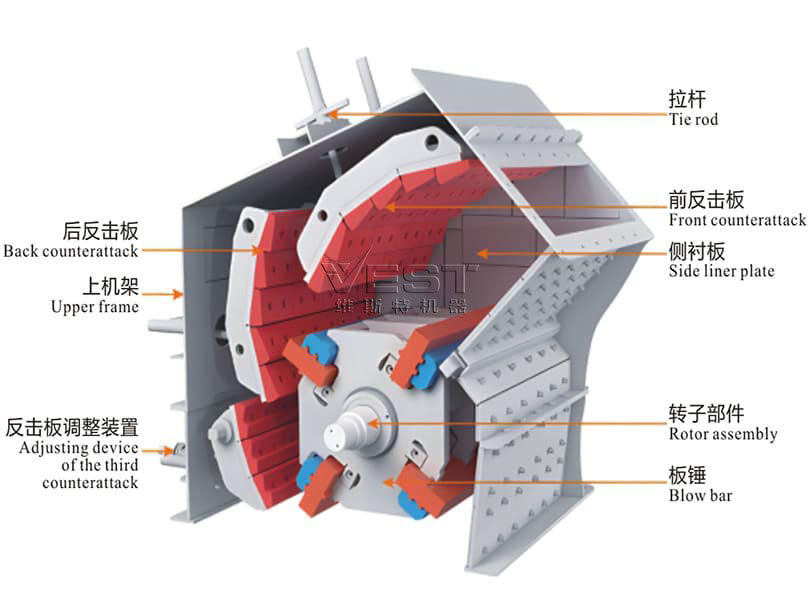

The advanced crushing chamber design and unique impact plate structure enable the material to undergo multiple impact crushing in the crushing chamber, which can quickly crush large-sized materials into small particles. The crushing ratio can be as high as 50 or more, which can effectively reduce the number of crushing stages and simplify the production process.

Through the multiple impacts and shaping effects of the impact plate and hammer on the material, the finished product has uniform particle size, cubic shape, and low needle-like content, which can meet the production needs of high-quality sand and gravel and is widely used in construction, road and other engineering fields that have high requirements on particle shape.

The rotor of the equipment has a large moment of inertia and a reasonable rotation speed, which can fully utilize the impact energy during the crushing process, effectively reduce energy consumption, and improve production efficiency. Compared with the same type of crushers, PFW impact crusher can increase the output by 20%-30% at the same power.

The modular design makes it easy to replace wearing parts. For example, the blow bar, impact plate and other components can be quickly disassembled and installed, which reduces the downtime of the equipment and improves the utilization rate of the equipment. Moreover, the structure of the equipment is relatively simple, and daily maintenance and servicing are relatively convenient, which reduces maintenance costs and labor intensity.

PFW impact crusher is widely used in many fields. In the construction industry, it is used to produce high-quality construction sand and gravel, providing high-quality aggregates for concrete, asphalt and other building materials; in the mining field, it can be used for coarse and medium crushing of various ores, such as iron ore, copper ore, etc.; in road construction, it can crush stones into suitable particle sizes for paving road base and subbase; in the chemical industry, some chemical raw materials can be crushed to meet the particle size requirements of subsequent processing.

The material enters the impact crusher from the feed port and falls onto the rotor of the crusher under the action of gravity.

A plate hammer is installed on the rotor. The rotor rotates at high speed driven by the motor, and the plate hammer rotates with the rotor. When the material comes into contact with the high-speed rotating hammer, it will be strongly impacted by the hammer, causing the weak parts of the material to break, thus achieving the first crushing.

The materials crushed by the plate hammer are thrown from the rotor to the impact plate on the top of the crusher under the action of centrifugal force. After the material collides with the impact plate, it is impacted and crushed again, then bounces back and collides with the plate hammer or other materials on the rotor, and is crushed multiple times.

Between the impact plate and the rotor, the material undergoes a continuous cycle of impact, rebound, and re-impact until the material is crushed to the required particle size.

When the particle size of the crushed material is smaller than the gap between the impact plate and the rotor, it will be discharged from the discharge port at the bottom of the crusher and become the finished product.

*The output will vary according to different materials, feed particle size and other factors

| Model | Feeder Openning Size(mm) | Max. Feeding Size(mm) | Rotor size(mm) | Motor Power(kw) | Capacity(t/h) |

| PFW-1007 | 400×730 | ≤250 | Φ1000×700 | 37-55 | 20-60 |

| PFW-1010 | 400×1080 | ≤300 | Φ1000×1050 | 55-75 | 50-90 |

| PFW-1210 | 400×1150 | ≤400 | Φ1250×1050 | 110-132 | 70-120 |

| PFW-1214 | 400×1500 | ≤430 | Φ1250×1400 | 132-160 | 100-170 |

| PFW-1315 | 860×1520 | ≤500 | Φ1320×1500 | 200-220 | 150-220 |

| PFW-1320 | 860×2030 | ≤500 | Φ1320×2000 | 260-315 | 160-350 |

| PFW-1520 | 1315×2040 | ≤700 | Φ1512×2000 | 400-450 | 300-450 |

| PFW-1620 | 1315×2040 | ≤700 | Φ1612×2000 | 500 | 400-550 |

| PFW-1820 | 1620×2040 | ≤700 | Φ1800×2000 | 630/710 | 550-800 |

| PFW-2022 | 1660×2460 | ≤800 | Φ2018×2238 | 900 | 800-1000 |

| PFW-2024 | 1800×2430 | ≤1200 | Φ2000×2400 | 1120 | 800-1000 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.