Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Mobile Sand-making Machine is an advanced rock-crushing equipment that can crush stones of various hardness and wear resistance.

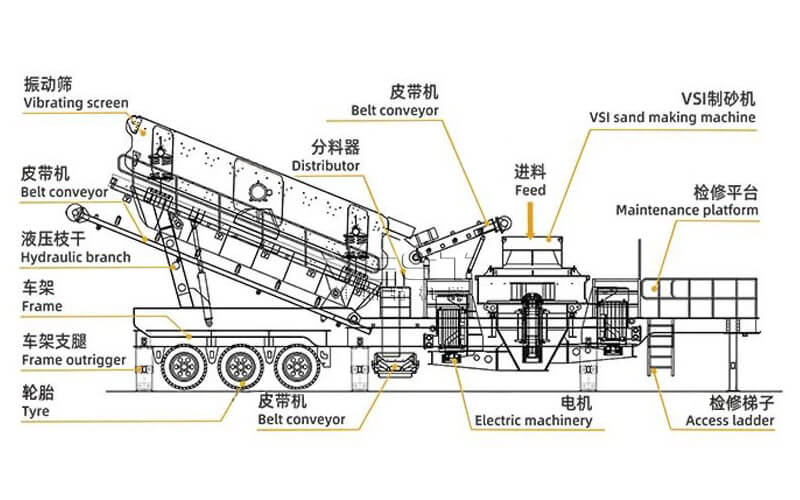

Mobile sand-making plants have three systems: feeding, crushing, and conveying. Equipped with a high-quality 5X/6X sand-making machine, the Tyre sand-making and shaping plant can operate much more stably and achieve higher capacity.

It can be quickly assembled into the required mobile station model, thus shortening the production time and delivery time.

All parts are vehicle-mounted, there is no need to dismantle parts for transportation, which is convenient for on-site installation. All-vehicle belt conveyor crushing plant, and there is no need for cranes and belt supports. With the adjustable landing leg, the foundation-free installation is practically realized.

The vibrating screen is self-lubricated by thin oil, which effectively saves labor costs and improves safe operation efficiency to ensure continuous production.

The new on-board integrated intelligent automatic control system makes the operation, maintenance, and adjustment of the crushing operation process more convenient and accurate.

The mobile sand-making station is equipped with a high-performance, large crushing ratio, and powerful crushing VSI series and 5X series sand-making machines. It is a piece of ideal equipment in the field of artificial sand making and stone shaping and can make the finished crushed products have reasonable grading.

The material, often crushed stone or rock, is fed into the mobile sand making plant through a vibrating feeder or hopper. This ensures a consistent and controlled flow of material into the sand making machine.

Inside the sand-making machine, the material is accelerated by a high-speed rotor and impacted against a stationary anvil or lining. This process fractures the material into smaller pieces and shapes it into sand. The design of the sand making machine determines the shape, size, and quality of the sand produced.

The sand is then screened to separate fine particles from coarser ones. The desired size fractions are collected, while oversized material is often re-circulated back into the sand making machine for further processing.

The processed sand is conveyed to stockpiles or discharge points. The plant can be configured to produce various grades of sand and aggregate, depending on the specific requirements of the application.

*The output will vary according to different materials, feed particle size and other factors

| VK Mobile Vertical Shaft Impact Crushing Station | ||||||

| Model | VK8518 | VK-5X8522 | VK9526 | VK-5X9532 | VK1140 | VK-5X1150 |

| Capacity (t/h) | 80-150 | 120-190 | 120-250 | 180-280 | 180-350 | 280-450 |

| Axle Qty | 2 | 2 | 2 | 2 | 3 | 3 |

| Vertical Shaft Impact Crusher | ||||||

| Model | VSI-8518 | VSI-5X8522 | VSI-9526 | VSI-5X9532 | VSI-1140 | VSI-5X1150 |

| Feeding size. (mm) | ≤40 | ≤45 | ≤45 | ≤45 | ≤45 | ≤45 |

| Motor Power(kw) | 2×90 | 2×110 | 2×132 | 2×160 | 2×200 | 2×250 |

| Throughput.t/h | 80-150 | 120-190 | 120-250 | 180-280 | 180-350 | 280-450 |

| Vibrating Screen | ||||||

| Model | YKR1548 | YKR1860 | YKR1860 | YKR2160 | YKR2160 | YKR2460 |

| Belt conveyor | ||||||

| Model | B650X6.5m | B800X7.2m | B800X6.7m | B1000X8.6m | B1000X6.4m | B1000X8.6m |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.