Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

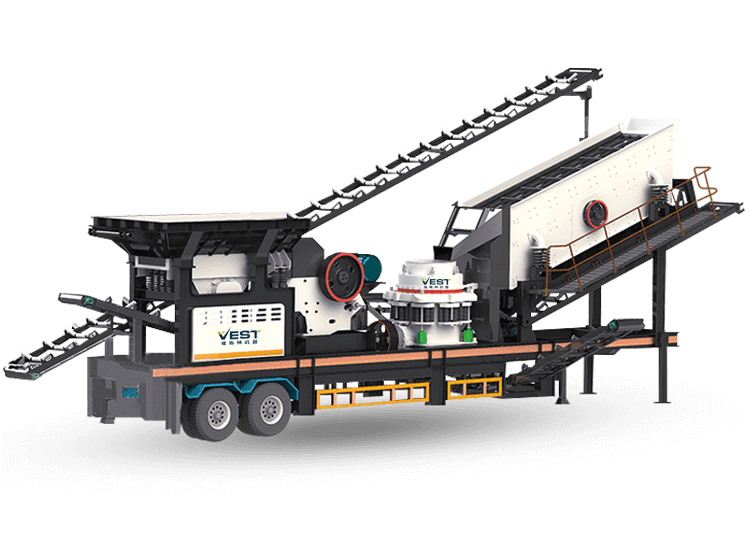

The Four Combinations Mobile Crushing Plant can crush a variety of stones, such as granite, basalt, limestone, etc. The feed size is usually less than 750mm, and the hourly output is 50-500 tons. It is widely used in mining, construction, road and bridge construction, construction waste treatment and other fields, and can complete stone crushing and processing tasks flexibly and efficiently.

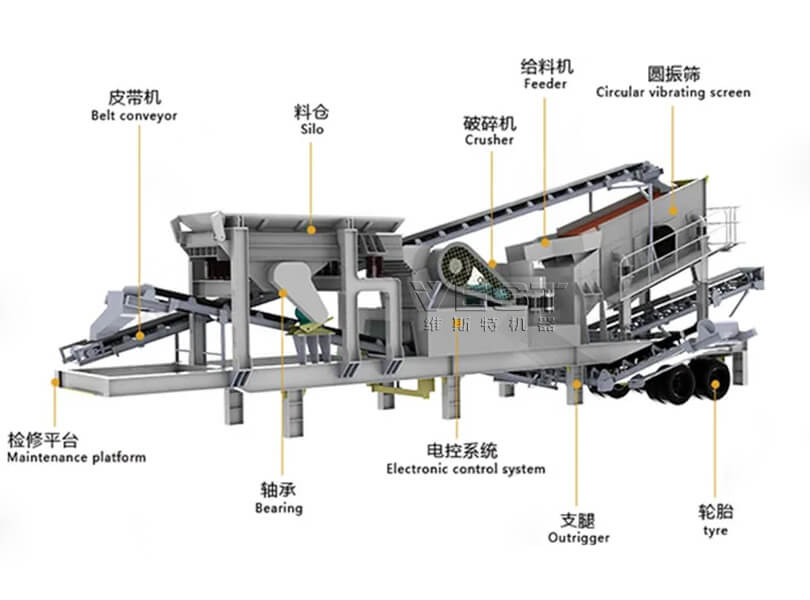

Four-in-one mobile crushing plant is a kind of efficient and flexible crushing equipment. It usually consists of four main parts: a feeder, two crushers (such as jaw crusher + cone crusher), a screener and a conveyor. Each part works together to crush and screen various ores, rocks and construction waste.

It integrates the four functions of feeding, crushing, screening and conveying, which reduces the equipment footprint and improves the overall operating efficiency.

Equipped with tires or crawler chassis, it does not require a fixed foundation and can be quickly transferred to different work sites to adapt to diverse working conditions.

Equipped with a PLC control system to monitor the equipment's operating status in real time, adjust crushing parameters, reduce manual intervention, and ensure stable production.

It adopts a closed structure and noise reduction design, and is equipped with an efficient dust removal system to meet environmental protection standards, while optimizing energy consumption and reducing operating costs.

The four-in-one mobile crusher is easy to move and can be quickly deployed and put into use in different work sites. It is widely used in mining, construction, road construction, solid waste treatment and other fields, effectively improving the efficiency and mobility of crushing operations.

Material feeding: First, the materials to be crushed are evenly and continuously fed into the crushing cavity of the crusher through a feeding device (such as a vibrating feeder).

Crushing process: In the crushing cavity, the materials are strongly impacted and squeezed by the crusher (such as a jaw crusher, cone crusher impact crusher, etc.), thereby being broken into smaller particles. The type and working principle of the crusher will vary according to the material properties, crushing needs, and finished product particle size requirements.

Screening process: The crushed materials are transported to the screening machine through the conveyor belt for screening. The screening machine uses vibration or other methods to separate materials according to particle size to obtain products of different particle sizes. The screen mesh or mesh size of the screening machine can be adjusted as needed to meet different screening requirements.

Product output: The screened products are transported to designated locations via conveyor belts for further use or storage. At the same time, materials with too large or too small particles produced during the screening process can be re-entered into the crusher through the return conveyor belt for re-crushing to achieve better particle size control.

*The output will vary according to different materials, feed particle size and other factors

| VKT Portable All-In-One Crushing Plant | ||||

| Model | VKT70-4 | VKT100-4 | VKT150-4 | VKT150-3 |

| Plant Power(KW) | 210.5 | 259.37 | 301.37 | 242.2 |

| Capacity (t/h) | 50-100 | 80-130 | 130-180 | 120-190 |

| Weight(ton) | 58 | 66.5 | 67.3 | 59.2 |

| Feeding Hopper | ||||

| Volume (m3) | 6 | 6 | 6 | 6 |

| Jaw Crusher | ||||

| Model | PE500×750 | PE600×900 | PE600×9000 | CI5X1213 |

| Motor Power (KW) | 55 | 75 | 75 | 160 |

| Max Feeding Size. (mm) | 425 | 500 | 500 | 550 |

| Cone Crusher | ||||

| Model | PYB900 | HST100H | HST160H | / |

| Motor Power(KW) | 55 | 90 | 132 | / |

| Max Feeding Size(mm) | 120 | 120 | 165 | / |

| Vibraating Feeder | ||||

| Model | ZSW8530 | ZSW9638 | ZSW9638 | ZSW1142 |

| Motor Power(KW) | 7.5 | 11 | 11 | 15 |

| YKR Vibrating Screen | ||||

| Model | 3YKR1548 | 3YKR1848 | 3YKR1860 | 3YKR1860 |

| Motor Power(KW) | 15 | 22 | 22 | 22 |

| Screen Mesh Size (mm) | 1500×4800 | 1800×4800 | 1800×6000 | 1800×6000 |

| Main Belt Conveyor | ||||

| Main Belt | B650 | B800 | B800 | B800 |

| Screen Feeder Belt (mm) | B650 | B800 | B800 | B800 |

| Side Belt Output (mm) | B500 | |||

| Side Belt output Height (mm) | 3000 | |||

| Return Belt conveyor (mm) | / | / | / | B500 |

| Under-Screen Belt | B1000 | |||

| Under-Screen Belt Output Height (mm) | 4100 | |||

| Note: Product models, parameters, appearance, etc . are constantly being improved. If any modifications cause differences please refer to the actual product received. | ||||

Have Any Questions!

Don't Hesitate To Contact Us Anytime.