Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

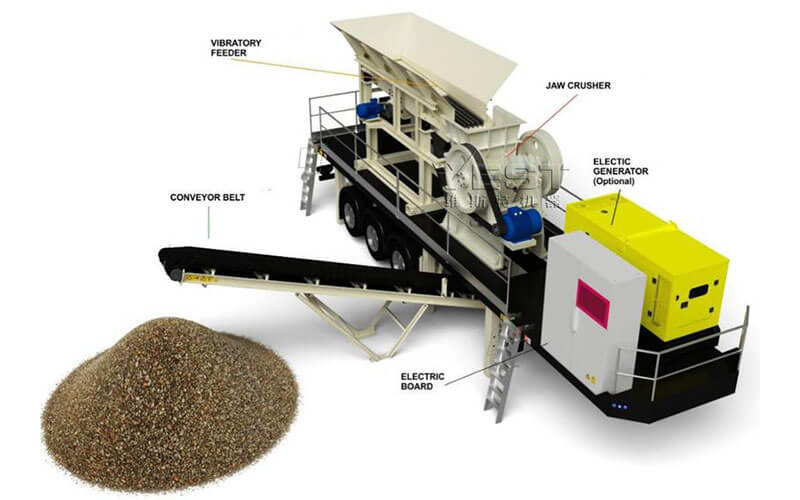

Tire-type mobile jaw crusher is a mobile crushing equipment that uses tires as walking devices and integrates feeding, crushing and screening. It can be flexibly moved to different work sites and can efficiently crush all kinds of stones.

Mobile jaw crushing plant is mainly used for crushing medium and high hardness stones, such as granite, basalt, river pebbles, etc. Feed particle size ≤750mm, output 10-500 tons per hour. It is mainly used in mining, construction engineering, road and bridge construction and other fields for coarse crushing of various stones.

Equipped with tire chassis, it can be freely and flexibly moved to different work sites to quickly carry out crushing operations.

The high manganese steel jaw plate and deep cavity crushing design can process rocks with a hardness of up to 350MPa. It has a large crushing ratio, stable output, and can efficiently complete the coarse crushing task.

It can adapt to complex and diverse working conditions and can operate stably no matter it is a mining site or a construction site.

It can be easily combined with other crushing and screening equipment to create a personalized crushing production line according to different production needs.

Mobile jaw crushing plant are widely used in the field of mining. They can directly crush the ore in the mining area to facilitate the subsequent mineral processing and beneficiation. In addition, they are also very useful in construction projects. They can flexibly crush various stones on the construction site to provide the required aggregates for concrete production, road infrastructure construction, etc.

The material is evenly transported to the crusher through the feeder and enters the crushing chamber; Meanwhile, the feeder can achieve pre-screening (for example, a grate gap of 25 mm, below 25 mm stones will be discharged directly and not enter into the crushing chamber) .

The Jaw crusher will crush big stones to small sizes, the discharging port can be adjusted.

The Main Belt conveyor will convey the crushed stone to the second line or directly as a stockpile.

The mobile jaw crusher plant is powered by a diesel engine or an electric motor, depending on the configuration.

*The output will vary according to different materials, feed particle size and other factors

| VK Tyre Portable Jaw Crushing Plant | |||||

| Model | VK46J | VK57J | VK69J | VK75J | VK90J |

| Capacity (t/h) | 40-80 | 60-120 | 100-200 | 150-300 | 150-350 |

| Length(mm) | 8600 | 9600 | 1 1097 | 13300 | 15800 |

| Width(mm) | 2520 | 2520 | 3759 | 2900 | 2900 |

| Height(mm) | 3770 | 3500 | 3500 | 4440 | 4500 |

| Feeding Hopper | |||||

| Volume(m³) | 3 | 4 | 7 | 10 | 10 |

| PE Jaw Crusher | |||||

| Model | PE400×600 | PE500×750 | PE600×900 | PE750×1060 | PE900×1200 |

| Max. Feeding Size(mm) | 350 | 425 | 500 | 630 | 750 |

| Discharge adjusting range(mm) | 40-90 | 50-100 | 60-125 | 80-150 | 95-165 |

| Capacity(t/h) | 15-60 | 40-130 | 90-180 | 110-380 | 220-550 |

| Feeder | |||||

| Model | GZD0725 | ZSW8530 | ZSW9638 | ZSW1149 | ZSW1360 |

| Motor Power(KW) | 5.5 | 7.5 | 11 | 45 | 22 |

| Belt conveyor | |||||

| Model | B650X6 | B800X7 | B1000X8 | B1000X11 | B1200X13 |

Note: Product models, parameters, appearance, etc . are constantly being improved. If any modifications cause differences please refer to the actual product received.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.