Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Wheel sand washing machine is used to wash and separate soil and other impurities in sand for the purpose of increasing sand quality.

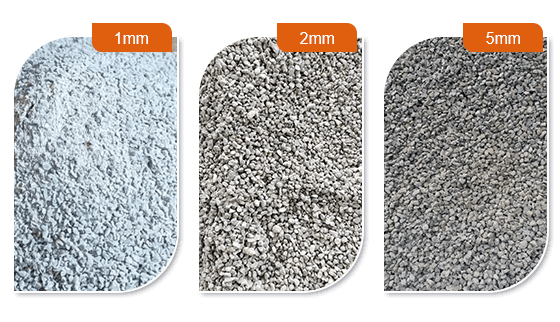

The XSD Series wheel bucket sands washing machine combines the conventional wheel bucket sands washing machine and grooved hydro classifier, which has a high recovery rate of fine sands, reasonable sands product grading, modest fineness modulus, less mud content, etc.

XSD has a high fine sand recovery rate, reasonable sand grading, moderate fineness modulus, and low mud content.

Adopt the punching screen mesh of superior steel, which is durable, of optimized mesh dimension and high sands washing cleanness.

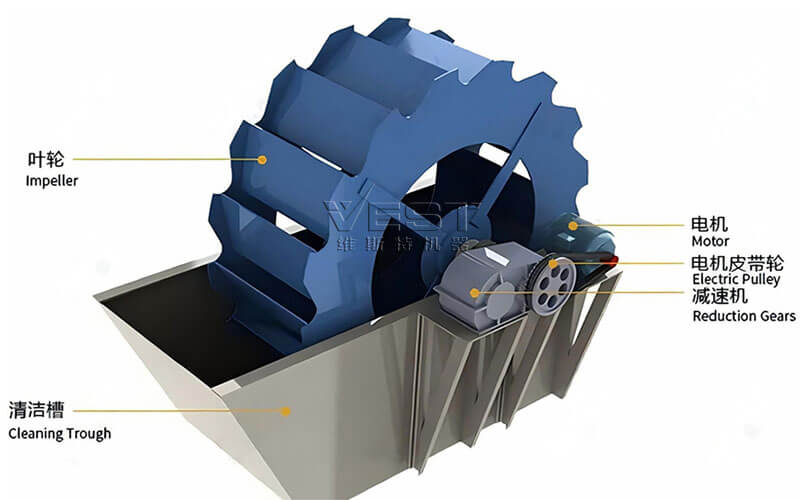

Reasonable design, new sealing structure, fully enclosed oil bath transmission device.Large capacity and low power consumption.

Easy operation and low maintenance cost.

Wheel sand washing machine is mainly used in construction sites, sand and gravel plants, hydropower station concrete dam sites, etc. to wash, grade and dehydrate various machine-made sand and natural sand to improve the quality of sand.

Bucket wheel sand washing machines are widely used in washing, grading, impurity removal, and other operations in metallurgy, building materials, hydropower, and other industries, especially for washing fine and coarse-grained materials.

When the XSD sand washing machine begins running, the impeller rotates slowly, driven by the motor and reducer, bringing sand and gravel from the feed chute into the wash tank cleaning, rotation of the impeller takes the water and sand away through the sieve, filtering out the clean sand.

Finally, gravel from the rotating impeller into the discharge chute and completion of the gravel cleaning effect.

*The output will vary according to different materials, feed particle size and other factors

| Model | Impeller Dia. (mm) | Feeding Size (mm) | Capacity (t/h) | Power (kw) |

| XSD2300 | φ2300 | ≤10 | 20-30 | 4 |

| XSD2610 | φ2600 | ≤10 | 30-80 | 7.5 |

| XSD2915 | φ2900 | ≤10 | 60-120 | 11 |

| XSD3016 | φ3000 | ≤10 | 80-160 | 15 |

| XSD3218 | φ3200 | ≤10 | 130-220 | 22 |

| XSD3420 | φ3400 | ≤10 | 160-300 | 22-30 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.