Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

GZT electromagnetic vibrating feeder is suitable for feeding material into the primary crusher in hydropower field, building material and mining.

GZT Series Vibrating Feeder adopts the vibrating motor to produce vibration force. It is used to feed material into the primary crusher homogeneously, and meanwhile, because of the bar-shaped screen, it can screen away soil contained in the raw material, increasing the capacity of the primary crushing.

It can be customized according to user requirements, and the feeding amount can be automatically or manually controlled.

It can be adjusted at any time, the flow rate can be changed and controlled, the vibration is stable, and the service life is long.

Using vibration motor to generate exciting force, low noise, low power consumption, good adjustment performance, no material rushing phenomenon.

Light weight, small size, easy maintenance. The machine body adopts a closed structure to prevent dust pollution.

GZT Series Vibrating Feeder is suitable for feeding material into the primary crusher in hydropower fields, building materials, and mining.

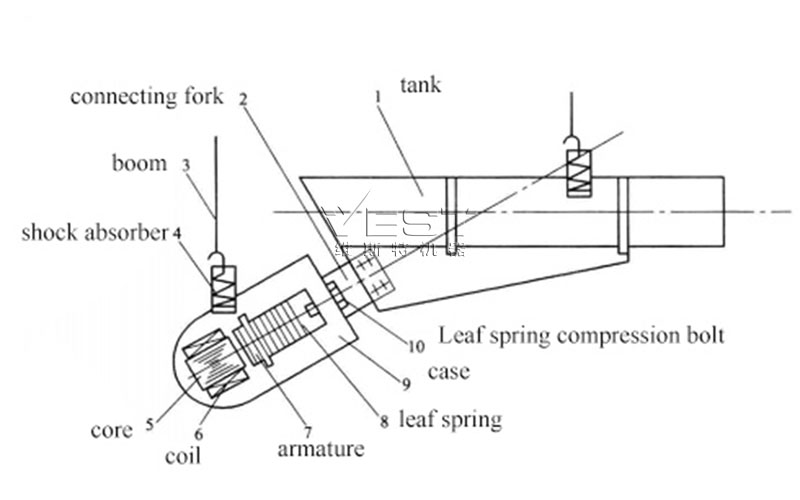

GZT Series Electromagnetic Vibrating Feeders adopt two vibrating motors with the same capabilities to produce the vibrating force.

When both of them make the motion of reverse rotation at the same angular velocity, the inertial force produced by the eccentric block is offset and summed up.

Thus the great exciting force compels the frame to vibrate in the spring support, which drives the materials to slide or be tossed forward on the frame and achieves the aim of feeding.

When the materials cross the grizzly fences, the small-sized materials fall through and achieve the effectiveness of sifting.

*The output will vary according to different materials, feed particle size and other factors

| Model | Max Feed Size (mm) | Capacity (t/h) | Motor Power (kw) | Installation Slope (°) | Double Amplitude (mm) | Overall Dimensions (LxWxH) (mm) |

|---|---|---|---|---|---|---|

| GZT-0724 | 450 | 30-80 | 2×1.5 | 5 | 4-6 | 700×2400 |

| GZT-0932 | 560 | 80-150 | 2×2.2(2×2.4) | 5 | 4-8 | 900×3200 |

| GZT-1148 | 600 | 150-300 | 2×5.5 | 5 | 4-8 | 1100×4800 |

| GZT-1256 | 800 | 300-500 | 2×12 | 5 | 4-8 | 1200×5600 |

| 400-600 | 2×12 | 10 | ||||

| GZT-1560 | 900 | 400-600 | 2×13 | 5 | 4-8 | 1500×6000 |

| 600-800 | 2×13 | 10 | ||||

| GZT-1860 | 1000 | 500-800 | 2×18 | 5 | 4-8 | 1800×6000 |

| 1000-1200 | 2×18 | 10 | ||||

| GZT-2060 | 1200 | 900-1200 | 2×18 | 5 | 4-8 | 2000×6000 |

| 1200-1500 | 2×18 | 10 | ||||

| GZT-2460 | 1400 | 1200-1500 | 2×21 | 5 | 4-8 | 2400×6000 |

| 1500-2500 | 2×21 | 15 | ||||

| GZT-3060 | 1600 | 1500-2000 | 2×25 | 5 | 4-8 | 3000×6000 |

| 2500-3500 | 2×25 | 15 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.