Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

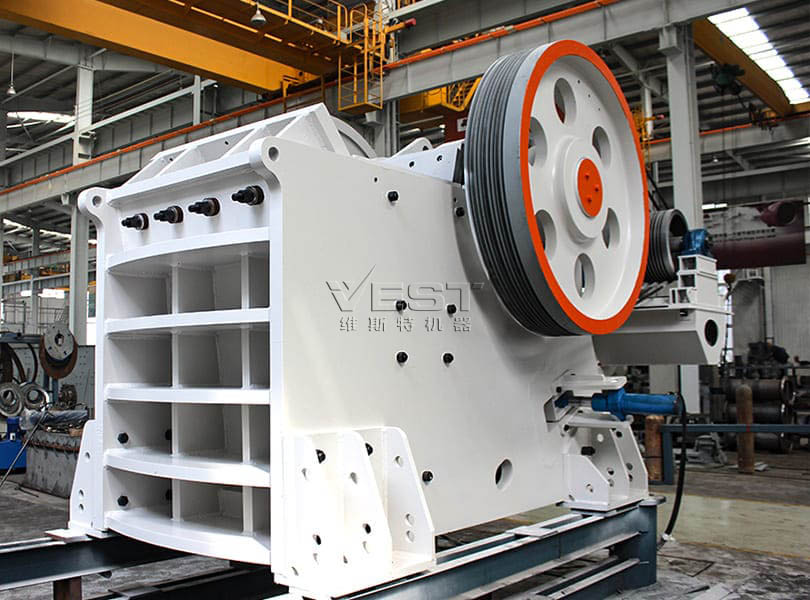

C Series jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications. The product family consist of models of different sizes that are engineered to deliver the maximum productivity at the lowest operating costs.

C series European jaw crusher combines outstanding performance, durability, intelligent design, and versatility. It is the ultimate choice for companies seeking to optimize their crushing operations, increase productivity, and achieve cost - effective solutions in today's competitive market.

The deep symmetrical design ensures higher capacity and uniform output, reducing energy consumption while maximizing productivity. This results in an impressive crushing ratio, allowing it to break down even the toughest materials with ease. Whether it's hard granite, basalt, or abrasive ores, the C series can process them into fine - sized particles in a single pass, significantly reducing the need for secondary and tertiary crushing operations in many cases.

Built with high-quality materials and reinforced components, the C Series offers extended service life even under heavy-duty conditions. This not only provides exceptional strength and stability during operation but also ensures long - term reliability. The key components, such as the jaw plates, are made from wear - resistant alloys, which can withstand the intense abrasion and impact associated with continuous crushing.

Featuring a hydraulic or wedge adjustment system, downtime is minimized, allowing quick and safe setting changes. The automated features, such as the hydraulic adjustment of the discharge opening, allow for quick and precise control over the output particle size. Operators can easily adjust the settings to meet different production requirements, without the need for complex manual operations. Additionally, the user - friendly interface provides real - time monitoring of key operating parameters, such as motor current, temperature, and vibration. This enables proactive maintenance and ensures that the crusher is always operating at peak efficiency.

The C series jaw crusher's motor and main unit are combined to save space and floor space. In order to adapt to the foundation requirements of fixed production lines and the portability requirements of mobile production lines, this type of jaw crusher has also been diversified in frame structure to maximize the performance of the C European version jaw crusher on different types of production lines. C80, C90,C100,C110,C125,C140,C160, those models for fixed crushing line. C96, C106,C116, C120, those model more prefer to portable crushing trailer.

The C series European jaw crusher is highly adaptable to a wide range of applications. In the mining industry, it serves as an ideal primary crusher for large - scale ore processing. In the construction and aggregates sector, it can produce high - quality aggregates for concrete production, road building, and other infrastructure projects. Moreover, it is also suitable for recycling applications, efficiently crushing construction and demolition waste into reusable materials. Its versatility makes it a valuable asset for any business involved in material processing.

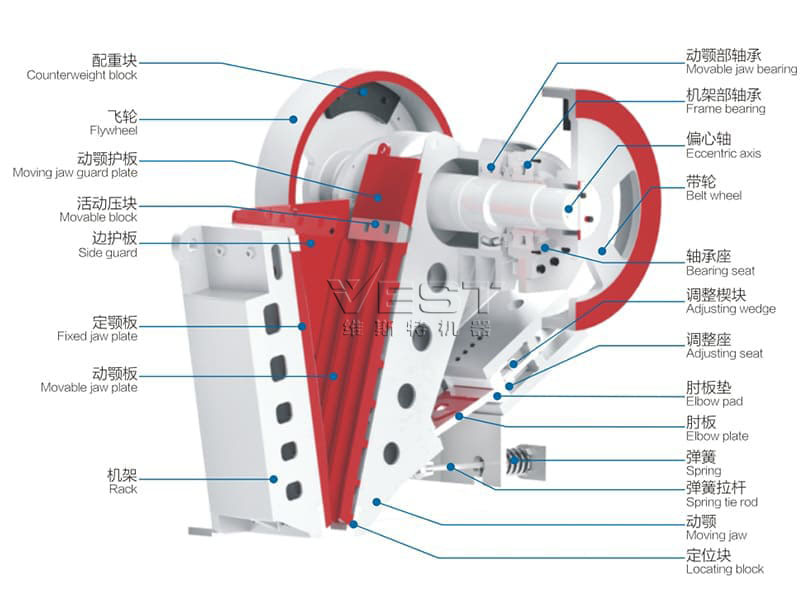

The raw material enters the crushing chamber through the top feed opening, guided by the vibrating feeder or direct loading. Then, The fixed jaw (stationary die) and the movable jaw (swing die) form the crushing cavity, with the movable jaw exerting force to break the material.

The whole Crushing Motion is an Elliptical Movement. The movable jaw is driven by an eccentric shaft (rotated by a motor via V-belts) that creates an elliptical motion pattern. As the shaft rotates, the movable jaw moves cyclically, Meanwhile, Forward stroke: Compresses material against the fixed jaw, crushing it.Return stroke: Releases crushed material downward by gravity, preparing for the next cycle.

Crushed material exits through the bottom discharge opening, with the stroke length and nip angle optimized to prevent clogging and ensure smooth flow. The discharge gap(closed-side setting/CSS) determines the final product size. Adjusted via hydraulic cylinders or mechanical shims (depending on model) to ensure consistent output gradation.

*The output will vary according to different materials, feed particle size and other factors

| Model | C80 | C96 | C100 | C106 | C116 | C110 | C120 | C125 | C130 | C140 | C145 | C150 | C160 | |

| Length of Input Port(mm) | 800 | 960 | 1000 | 1060 | 1150 | 1100 | 1200 | 1250 | 1300 | 1400 | 1400 | 1400 | 1600 | |

| Width of Input Port(mm) | 510 | 580 | 760 | 700 | 800 | 850 | 870 | 950 | 1000 | 1070 | 1100 | 1200 | 1200 | |

| Max Feed Edge(mm) | 450 | 500 | 650 | 580 | 650 | 700 | 700 | 800 | 850 | 860 | 1000 | 1000 | 1050 | |

| Eccentric Shaft Speed(rpm) | 350 | 330 | 260 | 280 | 260 | 260 | 230 | 220 | 220 | 220 | 220 | 220 | 220 | |

| Motor Power(kw) | 75 | 90 | 110 | 110 | 132 | 160 | 160 | 160-185 | 160-185 | 200 | 200 | 220 | 250-315 | |

| Product Size(mm) | Min Outlet Size(mm) | Capacity(t/h) | ||||||||||||

| 0-60 | 40 | 65-85 | ||||||||||||

| 0-75 | 50 | 80-95 | 105-135 | |||||||||||

| 0-90 | 60 | 95-125 | 125-155 | |||||||||||

| 0-105 | 70 | 115-150 | 140-180 | 155-210 | 150-185 | 170-210 | 190-250 | 175-240 | ||||||

| 0-120 | 80 | 130-170 | 160-200 | 170-225 | 165-215 | 180-235 | 210-275 | 195-270 | ||||||

| 0-135 | 90 | 150-195 | 175-225 | 190-245 | 190-235 | 205-255 | 235-305 | 210-305 | ||||||

| 0-150 | 100 | 165-215 | 220-280 | 215-280 | 205-265 | 230-285 | 255-330 | 235-325 | 290-380 | 270-370 | ||||

| 0-185 | 125 | 210-275 | 265-335 | 265-345 | 255-325 | 275-355 | 310-405 | 285-395 | 350-455 | 325-450 | 385-500 | 400-520 | 340-470 | |

| 0-225 | 150 | 250-325 | 310-390 | 315-410 | 305-385 | 320-405 | 370-480 | 340-475 | 410-535 | 380-525 | 455-590 | 470-610 | 400-555 | 450-640 |

| 0-260 | 175 | 290-380 | 350-455 | 370-480 | 355-450 | 375-465 | 425-550 | 385-540 | 470-610 | 435-600 | 520-675 | 540-700 | 460-635 | 520-730 |

| 0-300 | 200 | 420-545 | 395-500 | 420-540 | 480-625 | 530-690 | 490-680 | 590-765 | 610-795 | 520-720 | 588-830 | |||

| 0-340 | 225 | 590-770 | 545-755 | 655-850 | 680-885 | 580-800 | 655-920 | |||||||

| 0-375 | 250 | 650-845 | 600-835 | 725-945 | 750-975 | 640-880 | 710-1000 | |||||||

| 0-410 | 275 | 820-1070 | 780-1100 | |||||||||||

| 0-450 | 300 | 855-1200 | ||||||||||||

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.