Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

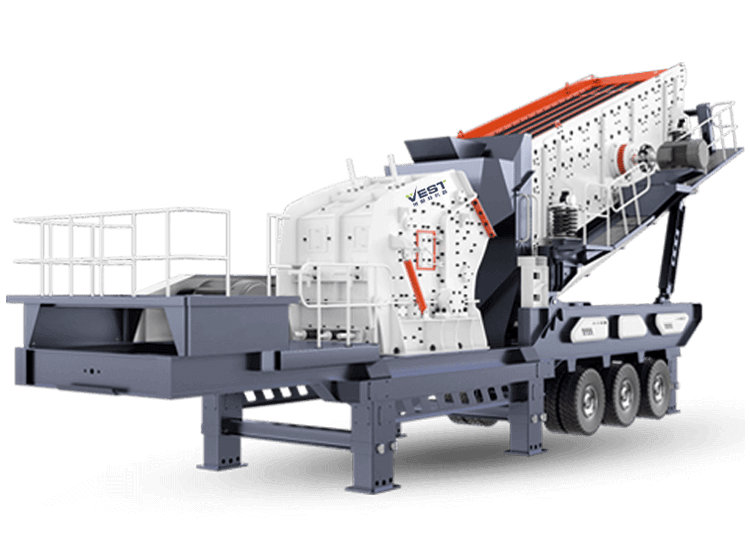

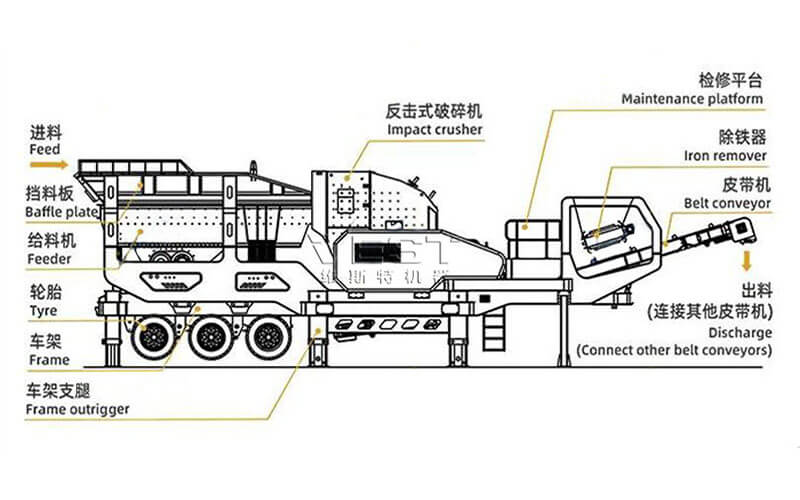

Mobile impact crusher is a highly efficient stone crushing equipment with the characteristics of flexible transfer, efficient crushing, and high-quality particle output. It is often used for crushing construction waste and other medium and low hardness stones.

Tire mobile impact crusher is suitable for crushing limestone, granite, sandstone, construction waste, cement blocks and other stone materials. The feed size is generally less than 500mm and the hourly output is 30-300 tons. It is mainly used in the fields of construction aggregate production, road engineering, mining, etc. It can crush large stones into particles that meet the requirements for use in concrete preparation, roadbed paving, etc.

Equipped with a tire-type traveling mechanism, it can be quickly transferred to different work points without assembly, greatly shortening downtime.

The multi-cavity impact plate and high-speed rotor design are adopted to achieve material impact crushing. The finished product has uniform particle shape and is suitable for medium-hard materials.

Equipped with a PLC automation system, it monitors the equipment's operating status in real time and supports remote adjustment of crushing parameters, making operation convenient and efficient.

The closed structure is combined with dust removal and noise reduction technology to reduce dust and noise pollution and meet strict environmental protection requirements.

Tire mobile impact crushing plant are commonly used in the construction industry. They can operate flexibly on construction sites and crush various types of stone into aggregates required for construction, providing basic materials for the construction of high-rise buildings, roads and bridges. They are also widely used in the field of mining and can efficiently perform coarse and medium crushing of ores, thus facilitating the development and utilization of mining resources.

The mobile impact crusher relies on the power provided by external electricity or an onboard generator to drive the main engine and auxiliary equipment motors.

The raw material will be fed into the impact crusher chamber to be impacted and squeezed in the crushing cavity, causing damage to its internal organization, thereby achieving crushing.

The crushed stones are returned to the vibrating screen of the mobile cone crusher through the belt conveyor for screening. The screened stones are transported to the finished product area strictly according to different specifications, and the large-sized stones are returned to the cone crusher for re-crushing, and then the screening is repeated until the finished product specifications are reached.

*The output will vary according to different materials, feed particle size and other factors

| VKF Impact Crushing Station (Transportation Size) | ||||

| Model | VKF1010R1548 | VKF121R1848 | VKF1214R1860 | VKF1315R2160 |

| Capacity (t/h) | 60-100 | 80-140 | 100-200 | 140-260 |

| Length(mm) | 10800 | 12200 | 12500 | 13500 |

| Width(mm) | 2480 | 2743 | 2900 | 2950 |

| Height(mm) | 4170 | 4200 | 4200 | 4200 |

| Weight (t) | 39 | 42 | 50 | 55 |

| Impact Crusher | ||||

| Model | PFW1010 | PFW1210 | PFW1214 | PFW1315 |

| Max Feeding Size(mm) | 300 | 400 | 430 | 500 |

| Feeding mouth(mm) | 400X1080 | 450X1080 | 480X1500 | 860X1520 |

| Capacity (t/h) | 50-90 | 70-130 | 100-180 | 130-220 |

| Motor Power(kw) | 55-75 | 90-110 | 132-160 | 160-220 |

| Magnetic Separator (optional) | ||||

| Vibrating Screen | ||||

| Model | 3YKR1548 | 4YKR1848 | 4YKR1860 | 4RYK2160 |

| Motor Power(kw) | 15 | 22 | 30 | 37 |

| Belt Conveyor | ||||

| Model | B500 | B650 | B800 | B1000 |

| Note: Product models, parameters, appearance, etc . are constantly being improved. If any modifications cause differences, please refer to the actual product received. | ||||

Have Any Questions!

Don't Hesitate To Contact Us Anytime.