Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

In industry, belt conveyors act as connections between different equipment to realize continuous and automatic production, which can improve efficiency and reduce labor intensity.

A belt conveyor is a mechanical system used to transport materials from one location to another. It consists of a belt that rotates around pulleys, allowing for the continuous movement of bulk materials, packages, or components.

It can not only transport various sand and gravel aggregates, sand coal, and other bulk materials but also transport various cartons, packaging bags, and other light-weight goods.

Including trough belt conveyor, flat belt conveyor, climbing belt conveyor, etc., and accessories such as push plates, side baffles, and skirts can also be added to the conveyor belt.

The conveying is stable, and there is no relative movement between the material and the conveyor belt, which can avoid damage to the conveyed objects.

The conveying belt is made of various materials such as rubber, canvas, PVC, PU, etc. In addition, it can also meet the conveying of materials with special requirements such as oil resistance, corrosion resistance, and anti-static.

Belt conveyors are widely used in mining, metallurgy, coal, ports, electricity, chemical industry and other industries due to their high efficiency and versatility.

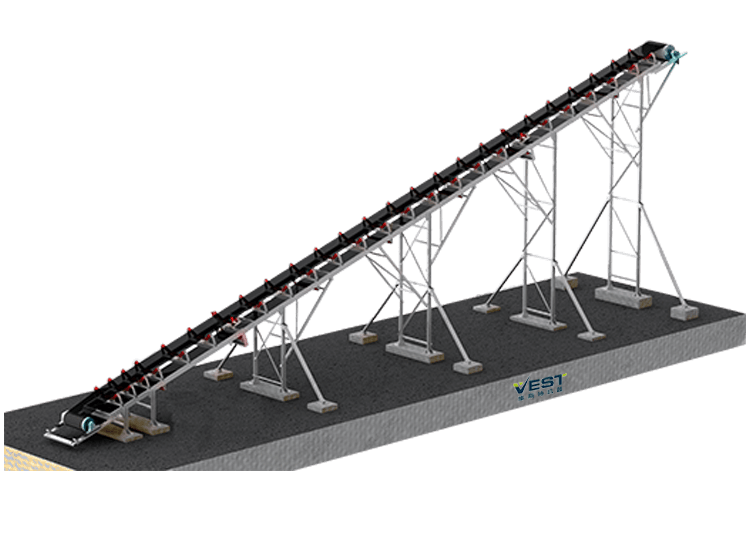

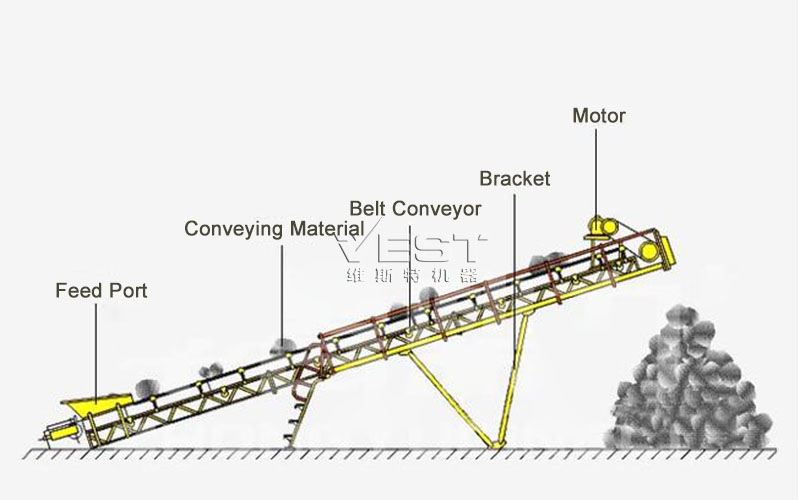

The conveyor is mainly composed of a frame, conveyor belt, belt roller, tensioning device, transmission device, etc. The body is made of high-quality steel plates.

The frame is formed by the height difference between the front and rear legs, and the plane is inclined at a certain angle. The frame is equipped with belt rollers, rollers, etc. to drive and support the conveyor belt.

There are two modes: reduction motor drive and electric roller drive.

*The output will vary according to different materials, feed particle size and other factors

| Model | Belt Width (mm) | Conveying length(m) / Power(kw) | Conveying speed (m/s) | Conveying amount (t/h) | ||

| B500 | 500 | ≤10 / 3 | 12-15 / 4-5.5 | 15-30 / 5.5-7.5 | 1.25-2.0 | 40-80 |

| B650 | 650 | ≤10 / 4 | 12-15 / 7.5 | 15-30 / 7.5-11 | 1.25-2.0 | 80-120 |

| B800 | 800 | ≤10 / 4 | 12-15 / 7.5 | 15-30 / 7.5-15 | 1.25-2.0 | 120-200 |

| B1000 | 1000 | ≤10 / 5.5 | 10-20 / 7.5-11 | 20-40 / 11-22 | 1.25-2.0 | 200-320 |

| B1200 | 1200 | ≤10 / 7.5 | 10-20 / 7.5-15 | 20-40 / 15-30 | 1.25-2.0 | 290-480 |

| B1400 | 1400 | ≤10 / 11 | 10-20 / 15-22 | 20-40 / 22-45 | 1.25-2.0 | 400-680 |

| B1600 | 1600 | ≤10 / 15 | 10-20 / 22-30 | 20-50 / 30-75 | 1.25-2.0 | 600-1080 |

| B1800 | 1800 | ≤10 / 18.5 | 10-20 / 30-45 | 20-50 / 45-110 | 1.0-2.0 | 800-1500 |

| B2000 | 2000 | ≤10 / 22 | 10-20 / 45-55 | 20-50 / 55-132 | 1.0-2.0 | 1000-2000 |

| B2400 | 2400 | ≤10 / 30 | 10-20 / 55-75 | 20-50 / 75-185 | 1.0-2.0 | 1500-3000 |

Note:

1. The conveying capacity in the table is obtained under the conditions of material density of 1.0t/m3-1.6t/m3, conveyor inclination angle ≤18°, and material stacking angle of 30°.

2. The density of the conveyable material is below 2.5t/m2.

3. The conveying length is not limited to the values listed in the table and can be manufactured according to user needs.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.