Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

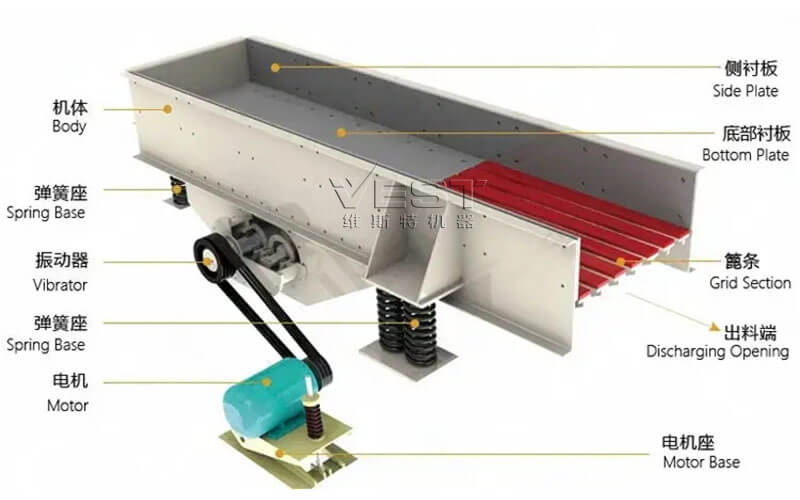

ZSW Series Vibrating Grizzly Feeder is mainly used to feed material into the primary crusher homogeneously and continuously. Meanwhile, it can screen the fine material and make the crusher more powerful.

ZSW series vibrating feeder is characteristic of the adoption of a double eccentric shaft exciter, which ensures that the machine can hold the impact force from bulk materials and improves the capacities. In the process of production, the feeder conveyors the grainy and bulk materials continuously and evenly to the targeted container, which prevents the container from crashing and prolongs the service life.

Stable operation, reliable work, long service life, easy installation, convenient maintain and easy automatic control.

Adopt double-shaft vibrator and liner vibrator to finish the feeding and screening process at the same time.

Continuously and evenly feeding for rough crusher to proceed the coarse screening.

Can install the variable-frequency and variable-speed motor to regulate frequency, change the production, and control the feed quantity easily without starting frequently.

ZSW Series Vibrating Grizzly Feeder are widely used in mining, metallurgy, coal, building materials and other industries to feed block and granular materials from silos or other storage equipment into crushing equipment evenly and continuously.

The ZSW vibrating feeder drives the trough to vibrate periodically through the exciting force generated by the vibrating motor, so that the material in the trough is continuously thrown up and transported forward under the action of inertia.

The specially made parallel bar grid at the bottom of the trough can pre-screen the material during the conveying process, so that fine particles fall directly through the grid gap, while large pieces of material continue to be transported along the trough to the downstream equipment, thus achieving simultaneous feeding and screening.

Its vibration parameters are adjustable, which can adapt to the uniform transportation of materials of different particle sizes and humidity, and is especially suitable for the front-end feeding and screening operations of coarse crushing in mining, building materials and other industries.

*The output will vary according to different materials, feed particle size and other factors

| Model | Size of Feed Spout (mm) | Max Feeding edge (mm) | Rotate Speed (r/min) | Motor Power (KW) | Capacity (t/h) |

|---|---|---|---|---|---|

| ZSW0930 | 3000×900 | 450 | 970 | 7.5 | 80~120 |

| ZSW3896 | 3800×960 | 600 | 500~800 | 11 | 120~250 |

| ZSW4211 | 4200×1100 | 700 | 500~800 | 15 | 180~400 |

| ZSW4911 | 4900×1100 | 750 | 500~800 | 18.5~22 | 250~500 |

| ZSW5911 | 5900×1100 | 750 | 500~900 | 22~30 | 300~550 |

| ZSW4913 | 4900×1300 | 750 | 500~900 | 22~30 | 400~600 |

| ZSW6015 | 6000×1500 | 1000 | 500~900 | 37~45 | 550~1200 |

| ZSW6018 | 6000×1800 | 1200 | 500~900 | 45~55 | 650~1300 |

| ZSW6021 | 6000×2100 | 1500 | 600~900 | 55 | 950~2000 |

| ZSW6025 | 6000×2500 | 1600 | 600~900 | 75 | 2000~3000 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.