Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

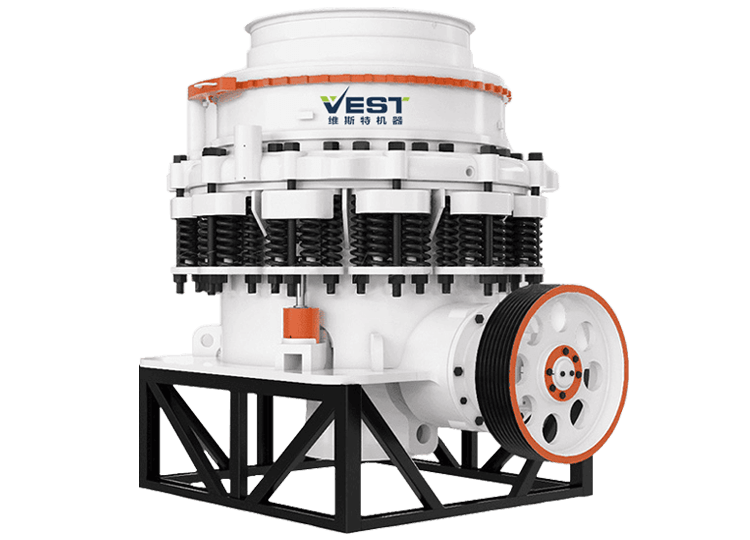

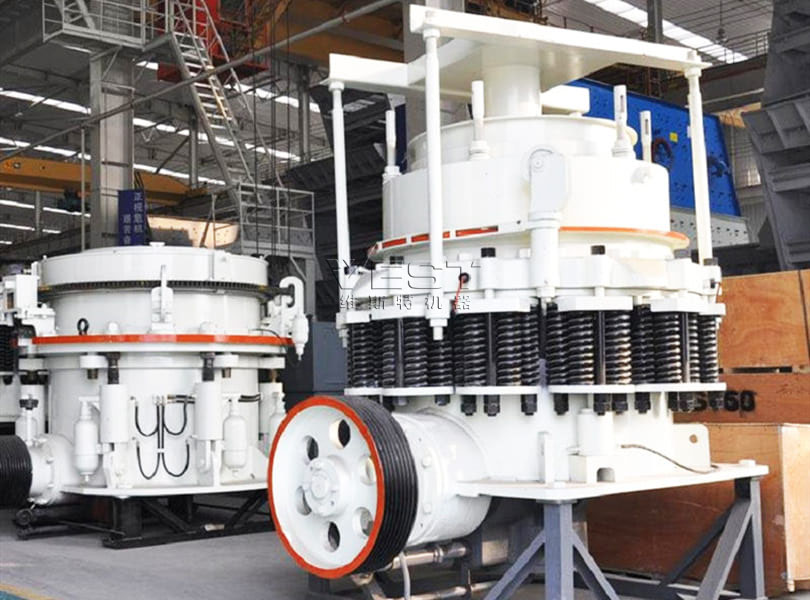

Symons cone crusher is an improved, optimized, and updated replacement product for the old spring cone crusher. Based on the principle of laminated crushing, it has developed into a modern high-performance cone crusher integrating high swing frequency, optimized cavity shape, and reasonable stroke. Symons cone crusher is suitable for various coarse, medium, and fine materials.

The CS Series Symons Cone Crusher is suitable for crushing all kinds of ores and rocks with medium or above hardness. Compared with PY Series Spring Cone Crusher it has the characteristics of reliable structure high production efficiency and convenient adjustment.

The CS Symons cone crusher boasts a unique crushing chamber design. The optimized mantle and concave configuration, along with a large stroke, endow it with a powerful and efficient crushing force. It can effortlessly process a wide variety of materials, from hard and abrasive rocks like granite and basalt to medium - hard ores. Continuous rotation of the operated cone body. Laminated crushing process makes the final material in good grain shape and big yield.

Constructed with a robust frame made from high - grade, heavy - duty steel, the CS Symons cone crusher ensures outstanding strength and stability during operation. The main shaft and other critical components are precision - engineered and crafted from top - quality alloys, capable of withstanding the intense stress and impact associated with continuous crushing work. The wear - resistant liners, especially those of the mantle and concave, are designed to endure severe abrasion, which greatly extends the service life of the crusher.

Half-hydrulic design make CS cone crusher more convenient at operation of discharging size adjustment, maintenance, compared with old spring cone crusher. Hydraulic or mechanical adjustment systems also allow quick setting changes with minimal downtime.

Optimized crushing motion and reduced friction lower power consumption per ton, saving operational costs. Meanwhile, Advanced crushing chamber geometry produces uniform, cubical end products, ideal for high-quality aggregates.

Suitable for a wide range of materials, from hard rock to fine aggregates, making it a highly adaptable crushing solution. Ideal for medium to hard rock crushing in mining, quarrying, and recycling industries. Its versatility and durability make it a preferred choice for secondary and tertiary crushing stages.

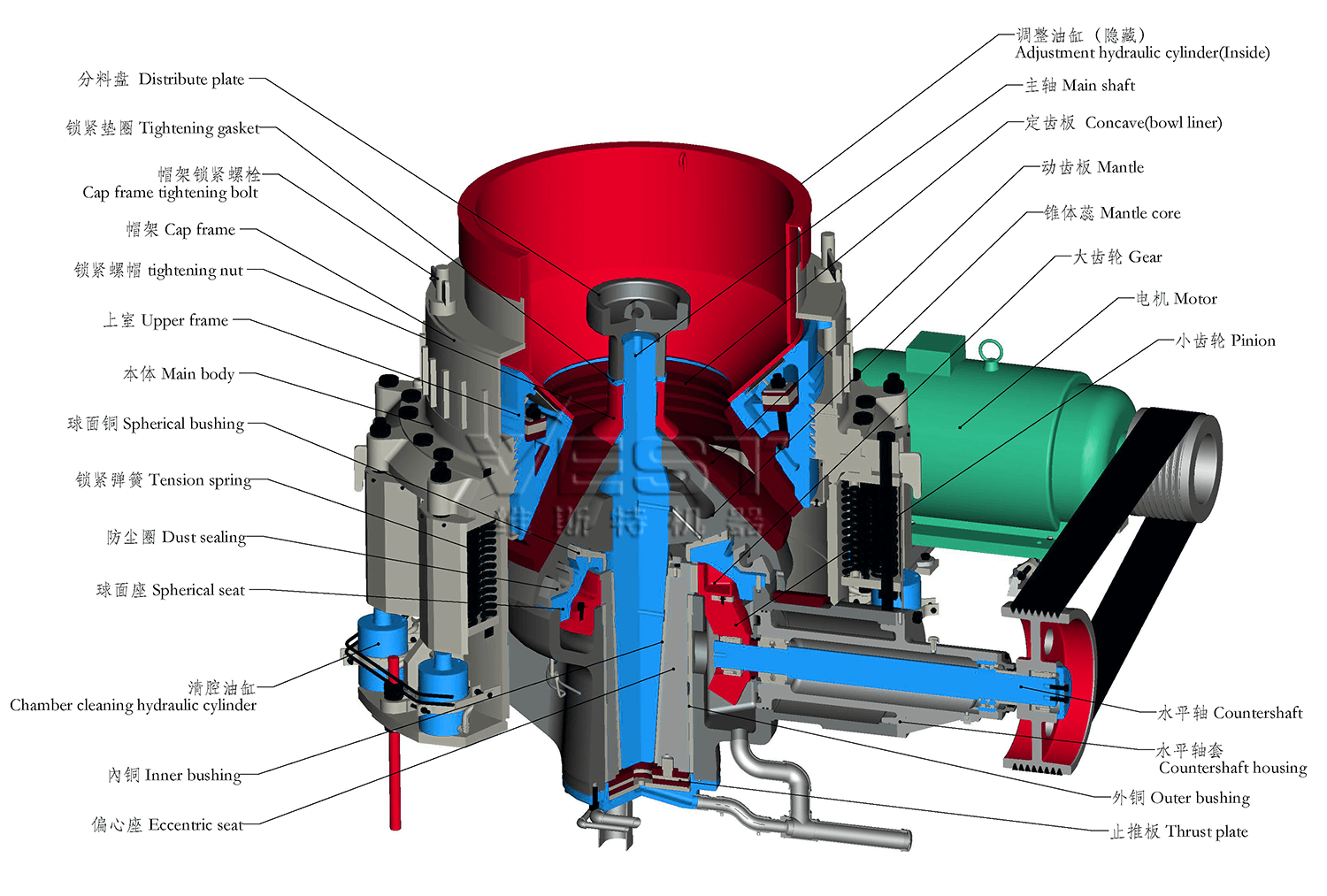

The spring cone crusher consists of a movable cone and a fixed cone to form a crushing chamber. The movable cone is pressed onto the main shaft (hard shaft), and one end of the main shaft is inserted into the conical hole of the eccentric sleeve. A bronze bushing or a nylon bushing is installed in the conical hole of the eccentric sleeve. When the transmission gear drives the eccentric sleeve to rotate, the main shaft deep inside the eccentric sleeve drives the movable cone to perform a swinging motion, so that the movable cone surface and the fixed cone are separated and combined from time to time, resulting in crushing and discharging of ore.

When the crusher is working, high-pressure oil enters the locking cylinder to raise the piston, slightly lift the locking nut and the adjustment ring, so that the serrated threads of the two are closely fitted in an inclined plane. When adjusting the discharge port, the locking cylinder needs to be depressurized to loosen the serrated thread, and then the hydraulic system is started to push the cylinder to move, thereby driving the adjustment ring to rotate left or right. With the help of the serrated thread transmission, the fixed cone is raised and lowered to achieve the purpose of adjusting the discharge port.

*The output will vary according to different materials, feed particle size and other factors

| Model | Cavity Type | Cone Diameter(mm) | Max. Feed Size(mm) | Outlet Setting Size(mm) | Capacity(t/h) | Power(kw) | Overall Dimension(mm) |

| CS75 | Coarse | 900 (3') | 150 | 25-38 | 59-163 | 75 | 2450X1820X2100 |

| CS75 | Medium | 900 (3') | 85 | 13-38 | 45-91 | 75 | 2450X1820X2100 |

| CS75 | Fine | 900 (3') | 35 | 6-20 | 27-90 | 75 | 2450X1820X2100 |

| CS110 | Coarse | 1200 (4') | 180 | 15-50 | 110-250 | 110 | 2485X2050X2445 |

| CS110 | Medium | 1200 (4') | 130 | 10-38 | 80-180 | 110 | 2485X2050X2445 |

| CS110 | Fine | 1200 (4') | 90 | 10-31 | 63-140 | 110 | 2485X2050X2445 |

| CS160 | Coarse | 1295 (4 1/4') | 205 | 19-50 | 172-349 | 160 | 2885X2320X2855 |

| CS160 | Medium | 1295 (4 1/4') | 178 | 16-38 | 132-253 | 160 | 2885X2320X2855 |

| CS160 | Fine | 1295 (4 1/4') | 115 | 13-31 | 109-181 | 160 | 2885X2320X2855 |

| CS220 | Coarse | 1400 (4 1/2') | 235 | 30-60 | 210-530 | 220 | 3153X2358X2750 |

| CS220 | Medium | 1400 (4 1/2') | 180 | 22-45 | 180-475 | 220 | 3153X2358X2750 |

| CS220 | Fine | 1400 (4 1/2') | 100 | 19-40 | 130-260 | 220 | 3153X2358X2750 |

| CS250 | Coarse | 1650 (5 1/2') | 228 | 30-60 | 299-635 | 250 | 3410X2620X3350 |

| CS250 | Medium | 1650 (5 1/2') | 205 | 25-50 | 258-417 | 250 | 3410X2620X3350 |

| CS250 | Fine | 1650 (5 1/2') | 178 | 20-45 | 181-327 | 250 | 3410X2620X3350 |

| CS315 | Coarse | 2135 (7') | 314 | 31-64 | 1125-1814 | 400 | 4613X3302X4638 |

| CS315 | Medium | 2135 (7') | 284 | 25-51 | 862-1424 | 400 | 4613X3302X4638 |

| CS315 | Fine | 2135 (7') | 236 | 19-38 | 544-1034 | 400 | 4613X3302X4638 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.