Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

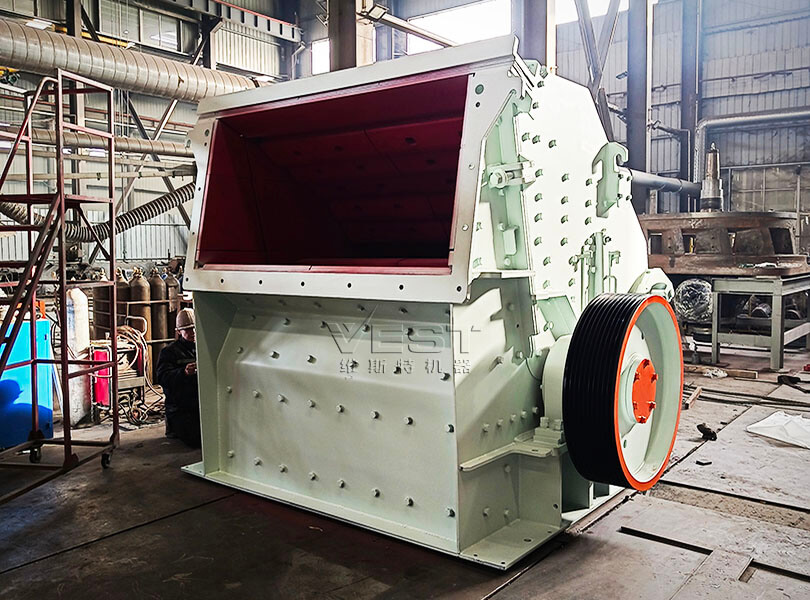

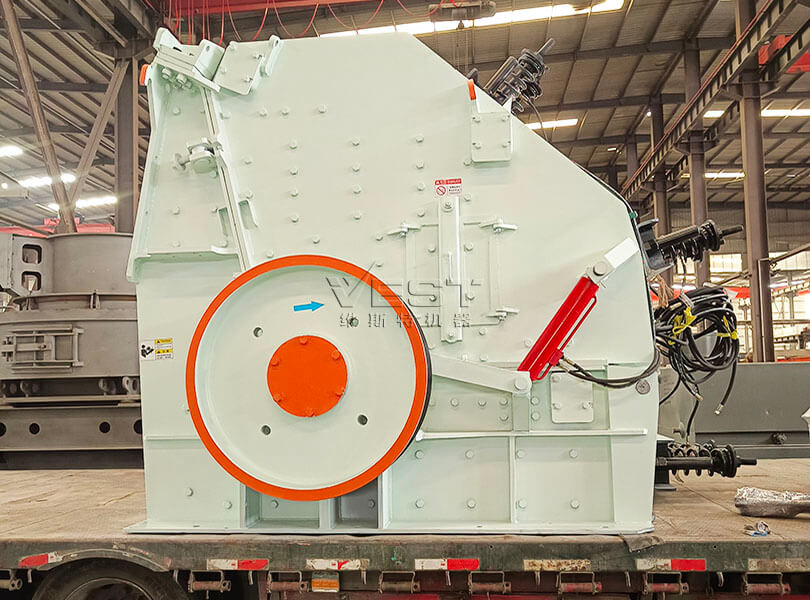

NP impact crusher is a highly efficient crushing equipment with the characteristics of large crushing ratio, good particle shape, stable operation and easy maintenance. It can process medium and low hardness stones with a size of about 50-700mm, and the output particle size can be flexibly controlled at about 0-30mm. It is widely used in construction and building materials, mining, chemical industry, metallurgy and other industries.

NP European impact crusher is a high-performance crushing equipment, which achieves high crushing ratio and excellent particle shape through unique design. It is suitable for crushing a variety of stones with medium and low hardness, the most common ones are limestone, dolomite, gypsum, shale, coal gangue, calcite, etc. These stones are widely used in construction, roads, chemical industry and other industries.

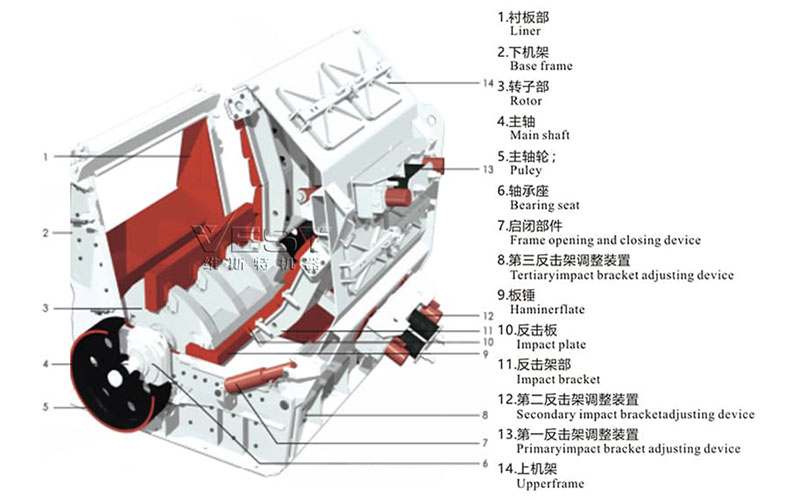

The unique crushing chamber design and plate hammer structure make the material subject to multiple impacts and counterattacks in the crushing chamber, which can crush larger stones into smaller particles and achieve a larger crushing ratio.

Through reasonable impact plate design and material movement trajectory control in the crushing chamber, the crushed material can be cubic, with low content of needle-like particles and uniform product particle size, which can meet the strict requirements of high-quality building aggregates on particle shape.

Using advanced manufacturing technology and high-quality components, the overall structure of the equipment is sturdy and durable, the rotor dynamic balance has high precision, and it can remain stable during high-speed operation, reducing the vibration and noise of the equipment, reducing the failure rate, and can operate continuously and stably, thereby improving production efficiency.

The equipment is designed for easy inspection and maintenance. For example, it adopts an easily disassembled component structure to facilitate the replacement of wearing parts such as blow bars and impact plates. The maintenance passage is spacious, so maintenance personnel can easily enter the equipment for inspection and repair, which shortens maintenance time and reduces maintenance costs.

The feed size of NP impact crusher is generally around 50-700mm, and the discharge size can be controlled in different ranges such as 0-5mm, 5-10mm, 10-20mm, 20-30mm, etc. to meet the needs of different users.

NP impact crusher is widely used in the field of construction materials to produce high-quality construction aggregates, such as for concrete production, road paving, etc. In the mining industry, it can crush various ores.

When the NP impact crusher is working, the motor drives the rotor to rotate at high speed through the pulley.

After the material enters the crushing chamber from the feed port, it is first impacted by the plate hammer on the high-speed rotating rotor and then thrown to the impact plate. The materials collide and impact repeatedly between the impact plate and the rotor and are constantly crushed.

At the same time, due to the effect of the impact plate, the material will be further refined by the rebound and shear force.

In this process, materials smaller than the discharge port size will be discharged from the bottom of the impact crusher, while larger materials will continue to be circulated and crushed in the crushing chamber until the required discharge particle size is reached.

*The output will vary according to different materials, feed particle size and other factors

| Model | Feeder Opening Size(mm) | Rotor size(mm) | Max. Feeding Size(mm) | Max Rotating Speed(rpm) | Motor Power (kw) | Capacity(t/h) |

| NP1007 | 750×800 | φ1000×700 | 500 (300) | 800 | 90-110 | 100-150 |

| NP1110 | 1020×820 | φ1100×1000 | 600 (300) | 800 | 132-200 | 150-250 |

| NP1213 | 1320×880 | φ1200×1300 | 600 (350) | 700 | 200-250 | 200-300 |

| NP1315 | 1540×930 | φ1300×1500 | 600 (400) | 700 | 250-355 | 300-400 |

| NP1520 | 2040×995 | φ1500×2000 | 700 (400) | 600 | 400-630 | 350-600 |

| NP1210 | 1020×1080 | φ1200×1000 | 800 (400) | 700 | 160-200 | 250-380 |

| NP1313 | 1320×1200 | φ1300×1300 | 900 (450) | 700 | 200-250 | 350-520 |

| NP1415 | 1540×1320 | φ1400×1500 | 1000 (600) | 600 | 250-315 | 400-600 |

| NP1620 | 2040×1630 | 1600×2000 | 1300 (700) | 500 | 400-500 | 650-950 |

| NP2023 | 2310×1980 | φ2000×2300 | 1500 (800) | 520 | 900-1200 | 1300-2000 |

| NP13 | 1320×560 | φ1200×1300 | 350 | 700 | 250-315 | 250-350 |

| NP15 | 1540×600 | φ1300×1500 | 400 | 700 | 315-355 | 300-400 |

| NP20 | 2040×700 | φ1500×2000 | 400 | 600 | 500-630 | 500-600 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.