Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

MTM European grinding mill is a highly efficient and energy-saving vertical roller mill, suitable for non-metallic minerals with Mohs hardness ≤ 9 (such as limestone, barite, calcite, etc.) and industrial solid waste resource processing. The finished product fineness can be adjusted to 80-600 mesh.

MTM Euro-type Grinding Mill is a highly efficient and energy-saving vertical roller mill, suitable for large-scale powder processing of non-metallic minerals with Mohs hardness ≤ 9 (such as limestone, calcite, barite, etc.). The fineness of the finished product can be flexibly adjusted between 80-600 meshes, and it has the characteristics of low energy consumption, high output and intelligent control.

MTM European grinding mills independently developed by our company have accumulated technology for many years, attracted the latest European powder ink concept, and achieved a technological revolution in industrial grinding mills, now with a number of independent patent technology property rights.

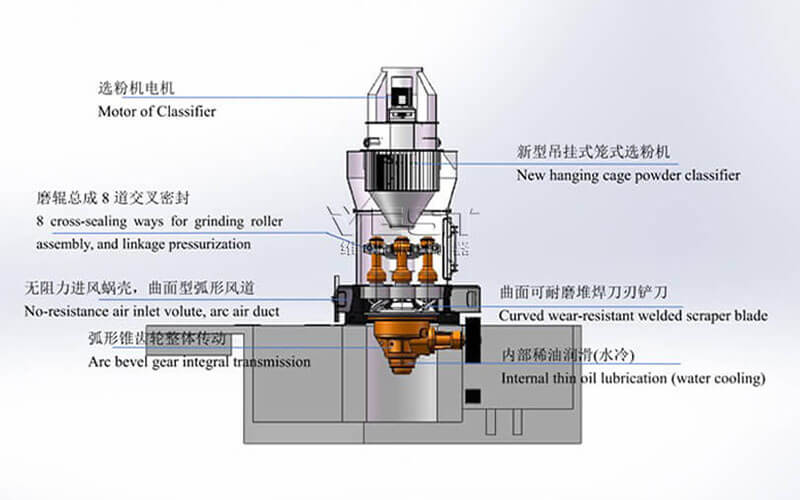

It adopts bevel gear integral transmission and thin oil lubrication technology, with low energy loss, high grinding efficiency, and power consumption reduced by 40%-50% compared with traditional equipment, making it suitable for large-scale production.

Through the dynamic airflow classification system and powder selector adjustment, the fineness of the finished product can be accurately controlled within the range of 80-600 mesh, meeting the needs of high-purity and wide-distribution powders.

The special curved grinding roller and high manganese steel grinding ring design, combined with the curved air duct, reduce material resistance, effectively increase the service life of components, and reduce the cost of use.

The integrated automatic control device and remote monitoring function realize the intelligent management of the whole process of crushing, drying, grinding and grading, which is easy to operate and has strong stability.

MTM European grinding mill is mainly used for fine grinding of non-metallic minerals (such as limestone, barite, calcite, etc.). The finished product fineness ranges from 80-600 mesh, meeting the high standards of building materials, chemical industry, metallurgy and other industries. It is also suitable for desulfurization in power plants, slag micropowder and industrial solid waste resource processing.

The raw materials that meet the feeding requirements are sent to the raw material warehouse by the forklift, and then the variable frequency belt feeder will evenly and continuously convey material into the main machine grinding chamber for grinding.

The ground powder will raised by the blower airflow, after being classified by the cage classifier, standard powder flows into the bypass cyclone collector to be separated and collected; the solenoid valve discharges standard powder. Airflow is inhaled in the air blower through the return duct upon bypassing the cyclone collector.

The whole flow air system is closed recirculation, and it flows in positive and negative pressure.

*The output will vary according to different materials, feed particle size and other factors

| Model | MTM1100 | MTM1500 | MTM1800 | MTM2000 | MTM2200 |

| Qty of Rollers(pcs) | 4 | 4 | 4 | 4 | 4 |

| Dia of Grinding ring x Height (mm) | φ1260X200 | φ1500X230 | φ1850X280 | φ2000X300 | φ2200X320 |

| Max Inlet size(mm) | 30 | 35 | 40 | 45 | 50 |

| Output size (mm) | 1.7~0.045 | 1.7~0.045 | 1.7~0.045 | 1.7~0.045 | 1.7~0.045 |

| Capacity (t/h) | 4~10 | 7~20 | 11~35 | 13~40 | 20~55 |

| Power (kw) | 55 | 110 | 200 | 220 | 315 |

| Overall Dimension(mm) | 8425x7933x8642 | 8600×9450×11050 | 9875×8400×9800 | 10500×8400×9800 | 11900×9300×12100 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.