Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

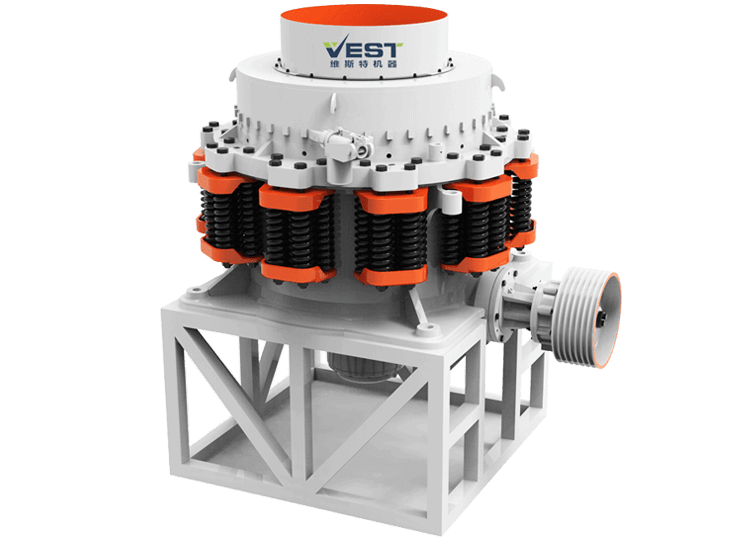

PY spring cone crusher is a kind of equipment suitable for crushing ores and rocks with medium or higher hardness. It has the characteristics of reliable structure, high production efficiency, convenient adjustment and economic use. It is widely used in metallurgy, construction, road construction and other industrial fields.

PY spring cone crusher is a kind of equipment suitable for crushing ores and rocks with medium or higher hardness. It has the characteristics of reliable structure, high production efficiency, convenient adjustment and economic use. It is widely used in metallurgy, construction, road construction and other industrial fields.

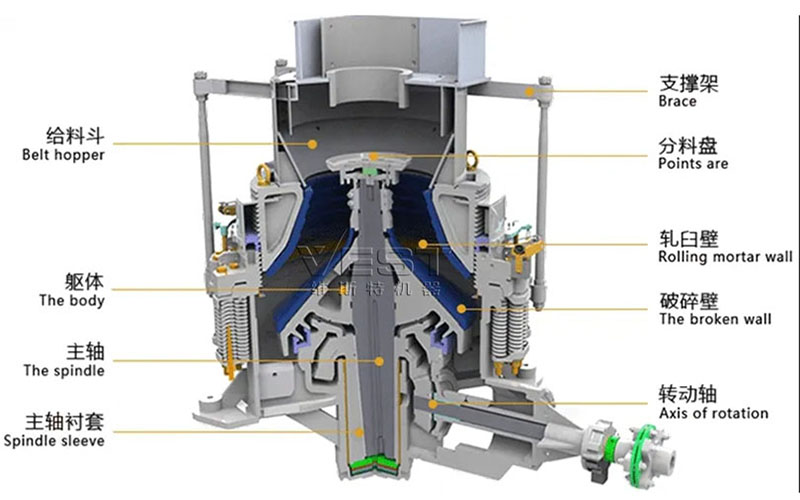

The material is squeezed by the movement of the mortar wall toward the crushing wall, so that the material is squeezed and ground multiple times in the crushing chamber, which can crush large particles into smaller particles and obtain a larger crushing ratio. It can effectively process ores and rocks of various hardness.

The lamination crushing principle is adopted to make the materials form a state of mutual extrusion and friction during the crushing process, so that the particle size of the finished product is more uniform. Products that meet different specifications can be produced to meet the needs of various industrial production.

Equipped with a spring safety device, when the crusher encounters uncrushable foreign objects or overload during operation, the spring will be compressed to enlarge the discharge opening, allowing foreign objects or excess materials to be discharged, thereby protecting the key components of the equipment from damage and improving the reliability and stability of the equipment.

Its structural design is reasonable, and the eccentric sleeve has a high rotation speed, which can enable the crushing wall to quickly extrude and crush the material. At the same time, the shape and size of the crushing chamber are optimized to increase the material processing capacity, process more materials per unit time, and improve production efficiency.

PY spring cone crusher is widely used in mining and metallurgical industries. It can perform medium and fine crushing of various metal ores such as iron ore and copper ore. It also performs well in the fields of construction and road construction. It can crush various rocks such as limestone and granite into different specifications to meet the needs of engineering construction.

Material is fed into the crushing chamber from the top. The mantle gyrates eccentrically, compressing and crushing the material against the concave. Crushed material falls through the discharge opening at the bottom, which can be adjusted to control the size of the output.

As rock enters the top of a cone crusher, it is squeezed between the shroud and bowl liner or concave surface as the eccentric shaft rotates causing compression in the cavity. The material becomes smaller as it moves downward through the wear lining as the opening in the cavity tightens. Large pieces of ore are crushed once and then fall to a lower level where they are crushed again. This process continues until the fragments are small enough to fall through the narrow opening at the bottom of the crusher.

*The output will vary according to different materials, feed particle size and other factors

| Model | Cone Diameter(mm) | Max. Feed Size(mm) | Outlet Setting Size(mm) | Capacity(t/h) | Power(kw) | Overall Dimension(mm) |

| PYB-600 | 600 (2") | 66 | 12-25 | 15-25 | 30 | 1740X1225X1940 |

| PYD-600 | 600 (2") | 36 | 3-13 | 5-23 | 30 | 1740X1225X1940 |

| PYB-900 | 900 (3") | 115 | 15-50 | 50-90 | 55 | 1990X1640X2380 |

| PYZ-900 | 900 (3") | 60 | 5-20 | 20-65 | 55 | 1990X1640X2380 |

| PYD-900 | 900 (3") | 40 | 3-13 | 15-50 | 55 | 1990X1640X2380 |

| PYB-1200 | 1200 (4") | 145 | 20-50 | 110-200 | 110 | 2805X2300X2980 |

| PYZ-1200 | 1200 (4") | 100 | 8-26 | 50-150 | 110 | 2805X2300X2980 |

| PYD-1200 | 1200 (4") | 50 | 3-15 | 18-105 | 110 | 2805X2300X2980 |

| PYB-1750 | 1750 (5 1/2") | 215 | 25-60 | 280-480 | 155-160 | 3610X2950X4185 |

| PYZ-1750 | 1750 (5 1/2") | 185 | 10-30 | 115-230 | 155-160 | 3610X2950X4185 |

| PYD-1750 | 1750 (5 1/2") | 85 | 5-15 | 75-230 | 155-160 | 3610X2950X4185 |

| PYB-2200 | 2200 (7") | 300 | 30-60 | 590-1000 | 260-280 | 4790X3430X5080 |

| PYZ-2200 | 2200 (7") | 230 | 10-30 | 200-580 | 260-280 | 4790X3430X5080 |

| PYD-2200 | 2200 (7") | 110 | 5-16 | 120-370 | 260-280 | 4790X3430X5080 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.