Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

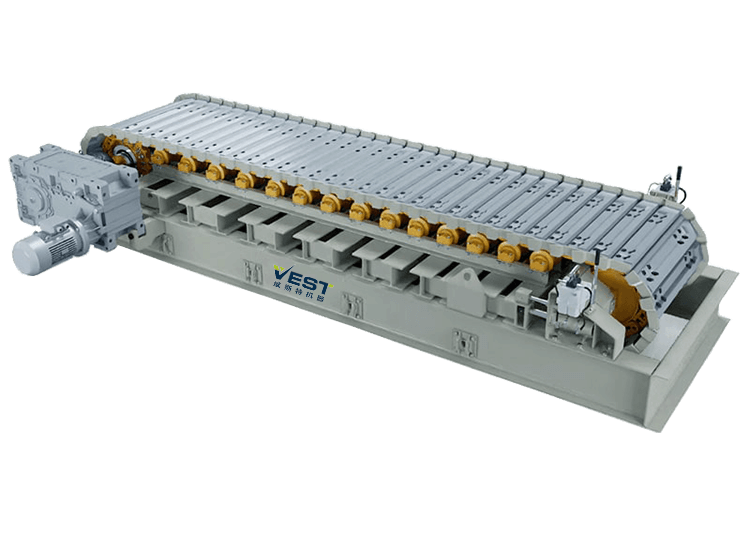

The apron feeder is a bulk material conveying equipment that converts intermittent feeding into continuous feeding.

BW series apron feeder is to convey loose material, which changes the traditional intermittent feeding method to a continuous feeding method.BW series apron feeder not only gets used to different working environments but also to different material conditions such as humidity, viscosity, etc. The apron feeder is widely applied among quarries and mines, cement factories, road construction, etc.

The slot plate adopts a stamping and welding structure with a large load-bearing capacity.

For BW type, the tail has sleepers to absorb vibration, and the middle has vibration-absorbing rollers to support, which increases the service life of the running parts.

Large traction, less leakage, and smooth operation.

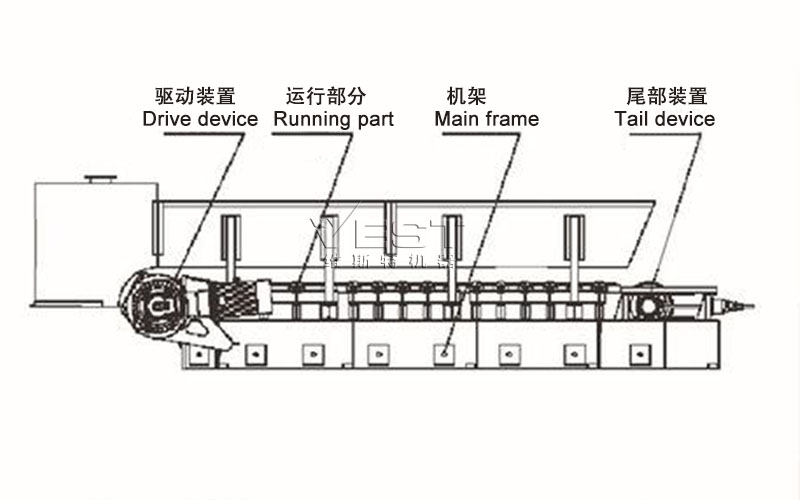

The drive device adopts a suspended single-point floating support method to reduce the radial installation size of the plate feeder.

The apron feeder is widely used for transporting high-capacity, high-water-content, and high-viscosity materials.

A high-strength bulldozer die-forged chain with a pitch of 228.6mm (9 inches) is used as the traction part. Two chains are connected to form a closed loop by passing through a pair of driving sprockets installed at the head of the machine body and a pair of tensioning wheels at the tail of the machine body. Each link of the two rows of chains is equipped with overlapping, heavy-duty conveying troughs to form a continuous conveying line capable of carrying materials.

Its dead weight and the weight of the materials are supported by multiple rows of supporting rollers, chain support wheels, and slideway beams installed on the machine body. The transmission system is connected to the reducer through an AC variable frequency speed regulating motor, and then the expansion sleeve is directly connected to the drive device to drive the carrying mechanism to run at a low speed.

The materials unloaded from the tail silo are transported to the front of the machine body along the conveying line for discharge, to achieve the purpose of continuous and uniform feeding to the working machinery below.

*The output will vary according to different materials, feed particle size and other factors

| Model | Funnel Width (mm) | Max Feed Edge (mm) | Center Distance Between Head and Tail Drums | Capacity (t/h) | Motor Power (kw) |

| BW1000 | 1000 | 500 | The Length Can Be Customized According To Clients' Requirements. | 80-160 | 11-15 |

| BW1200 | 1200 | 600 | 100-200 | 11-30 | |

| BW1250 | 1250 | 650 | 100-250 | 11-18.5 | |

| BW1400 | 1400 | 700 | 120-290 | 15-22 | |

| BW1500 | 1500 | 700 | 280-460 | 15-45 | |

| BW1600 | 1600 | 800 | 300-600 | 22-30 | |

| BW1800 | 1800 | 800 | 500-900 | 37-45 | |

| BW2200 | 2200 | 1200 | 600-1400 | 45 | |

| BW2300 | 2300 | 1300 | 800-1600 | 55 | |

| BW2400 | 2400 | 1500 | 1000-1900 | 75 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.