Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Crawler cone crushing plant is an all-purpose, compact and modular mobile crushing plant for aggregates and recycling industries.

Crawler-type cone crushing plant, which can be used as secondary or tertiary crushing in the whole crushing work, is a state-of-the-art mobile crushing solution designed for high-performance and versatility in material processing. Combining the power of a cone crusher with the mobility of a tracked chassis, this plant delivers exceptional crushing capabilities while offering unmatched flexibility and ease of transportation.

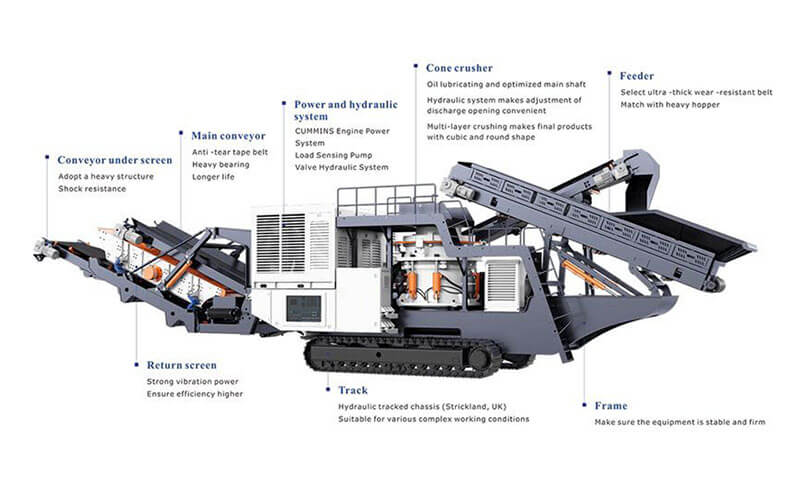

The plant is mounted on a robust tracked undercarriage, which provides excellent mobility and stability. This design allows the plant to navigate various terrains, including rough, uneven surfaces, and confined job sites, making it ideal for both urban and remote locations.

Crawler cone crusher known for its superior crushing performance. The cone crusher utilizes a rotating cone and a stationary bowl to crush materials through compression. This mechanism delivers a high reduction ratio and produces finely graded end products with a consistent shape and size.

The tracked cone crushers are widely used in quarrying, mining, construction and recycling. Its ability to process hard and abrasive materials makes it an essential tool for producing high-quality aggregates and managing various material processing needs.

Built to withstand demanding conditions, the plant features a durable and rugged construction. The tracked chassis ensures stability and durability, while the cone crusher components are designed for long-lasting performance and minimal maintenance requirements.

Crawler cone crusher is mainly used to crush various ores and rocks with higher hardness such as iron ore, copper ore, granite, basalt, etc. In addition, it is widely used in mining, metal ore dressing plants, construction aggregate processing and other fields. It is often used in two-stage and three-stage medium and fine crushing operations to produce high-quality finished aggregates.

Materials are fed into the crushing plant through a primary feeding system, typically a vibrating feeder or similar device. The feeder ensures that materials are distributed evenly into the cone crusher

In the cone crusher, the material is fed into the top of the crusher chamber where it is crushed between a rotating cone (mantle) and a stationary bowl liner (concave). The rotating cone moves eccentrically, creating a crushing force that compresses and breaks down the material into smaller pieces.

Once the material has been sufficiently crushed, it is discharged through the bottom of the cone crusher. The crushed material is then transferred to a conveyor belt system that carries it away from the crusher for further processing or stockpiling.

*The output will vary according to different materials, feed particle size and other factors

| Tracked Portable Cone Crushing Plant | |||||||

| Model | VTH90CS | VTH160CS | VTH160C | VTH250CS | VTH250C | VTH315CS | VTH315C |

| Plant Power (KW) | 211.3Kw+90Kw | 211.3Kw+90Kw | 185Kw+70Kw | 301.3Kw+115Kw | 272Kw+90Kw | 374.9Kw+115Kw | 348Kw+115Kw |

| Capacity (t/h) | 60-250 | 100-280 | 120-400 | 200-500 | |||

| Sizes L×W×H (mm) | 16500×3300×3700 | 17000×3300×3700 | 16400×2950×3600 | 17800×3500×3750 | 17400×3300×3800 | 22000×3750×4100 | 20000×3500×3800 |

| Belt Feeder | |||||||

| Model | B800×7000 | B1000×7000 | B1000×7000 | B1000×7000 | B1000×7000 | B1200×8000 | B1200×8000 |

| Power (kw) | 7.5 | 11 | 11 | 11 | 11 | 15 | 15 |

| Feeding Height (mm) | 2580 | 2580 | 2580 | 2580 | 2580 | 2680 | 2680 |

| Volume (m3) | 3.5 | 5 | 5 | 5 | 5 | 3 | 3 |

| Cone Crusher | |||||||

| Model | MHP100/MCH420 | MHP200/MCH430 | MHP200/MCH430/PSG155 | MHP300/MCH440/MGP300 | MHP300/MCH440/MGP300 | MHP400/MCH660 | MHP400/MCH660 |

| Power (kw) | 90 | 160 | 160 | 250 | 250 | 315 | 315 |

| Main Discharge Belt | |||||||

| Size (mm) | B800×9000 | B1000×9500 | B1000×10000 | B1000×9500 | B1000×10000 | B1200×12000 | B1200×10000 |

| Discharge Height (mm) | 2700 | 2800 | 2500 | 2800 | 2500 | 2900 | 2800 |

| Power (kw) | 7.5 | 11 | 11 | 11 | 11 | 15 | 15 |

| Inspection Screen | |||||||

| Model | 2YKR1335 | 2YKR1435 | ———— | 2YKR1435 | ———— | 2YKR1545 | ———— |

| Power (kw) | 2×3.7 | 2×3.7 | ———— | 2×3.7 | ———— | 2×5.5 | ———— |

| Discharge Belt Under-Screen | |||||||

| Size (mm) | B1000×6500 | B1200×6500 | ———— | B1200×6500 | ———— | B1200×6500 | ———— |

| Discharge Height (mm) | 2600 | 2600 | ———— | 2600 | ———— | 2600 | ———— |

| Power (kw) | 7.5 | 7.5 | ———— | 7.5 | ———— | 7.5 | ———— |

| Transition Belt 1# | |||||||

| Size (mm) | B500×2000 | B500×2000 | ———— | B500×2000 | ———— | B650×2000 | ———— |

| Discharge Height (mm) | 1300 | 1300 | ———— | 1300 | ———— | 1300 | ———— |

| Power (kw) | 2.2 | 2.2 | ———— | 2.2 | ———— | 2.2 | ———— |

| Transition Belt 2# | |||||||

| Size (mm) | B500×2000 | B500×2000 | ———— | B500×2000 | ———— | B650×2000 | ———— |

| Discharge Height (mm) | 900 | 900 | ———— | 900 | ———— | 1300 | ———— |

| Power (kw) | 2.2 | 2.2 | ———— | 2.2 | ———— | 2.2 | ———— |

| Screen Front Side Discharge Belt | |||||||

| Size (mm) | B500×4500 | B500×4500 | ———— | B500×4500 | ———— | B650×4500 | ———— |

| Discharge Height (mm) | 2000 | 2000 | ———— | 2000 | ———— | 2000 | ———— |

| Power (kw) | 3 | 3 | ———— | 3 | ———— | 3 | ———— |

| Returning Belt Conveyor | |||||||

| Size (mm) | B500×8200 | B500×8200 | ———— | B500×8200 | ———— | B650×9200 | ———— |

| Discharge Height (mm) | 3900 | 3900 | ———— | 3900 | ———— | 3900 | ———— |

| Power (kw) | 4 | 4 | ———— | 4 | ———— | 4 | ———— |

| Dual-power Assembly | |||||||

| Driving Mode | Diesel — electricity | ||||||

| Note: Product models , parameters , appearance , etc . are constantly being improved. If any modifications cause differences please refer to the actual product received. | |||||||

Have Any Questions!

Don't Hesitate To Contact Us Anytime.