Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

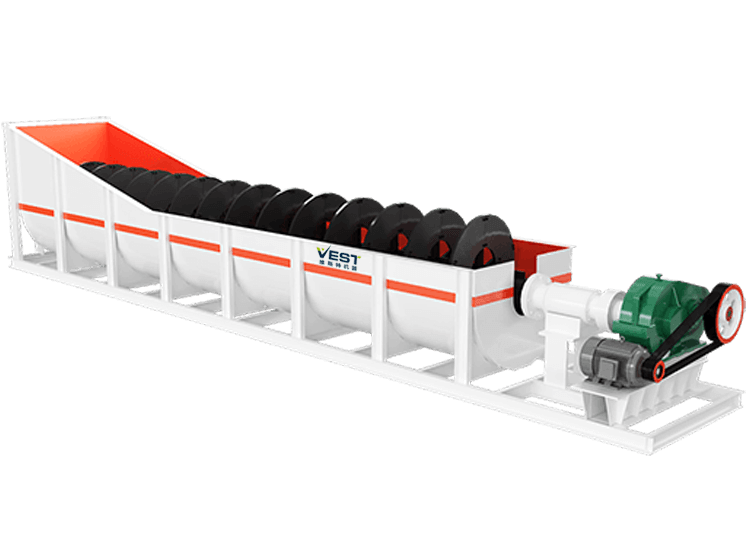

Spiral Sand Washers can wash and separate the soil and foreign material in the sand. Its novel structure, adjustable overflow dam baffle and reliable arrangement can make sure the result of the wash.

The spiral sand washing machine can efficiently clean the dirt and impurities in the sand and gravel through the stirring and lifting action of the spiral blades, and has the significant advantage of good cleaning effect.

The impeller drive bearing device is isolated from water and water-receiving materials, which greatly avoids the bearing damage caused by water immersion, sand, and pollutants and has a low failure rate.

The fittings are highly matched, the operation is relatively stable, and the wearing parts are made of highly wear-resistant and pressure-resistant raw materials. The whole machine has a low failure rate and is durable.

It has a high degree of cleaning, and the sewage can be recycled, which effectively saves resources and increases the output of the whole machine.

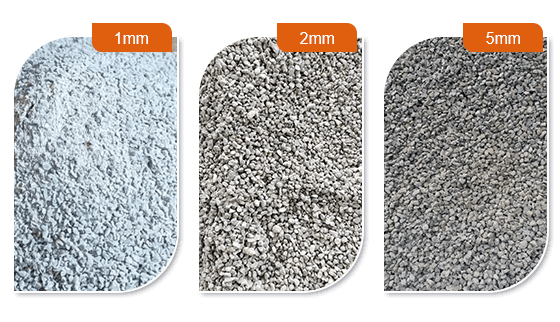

There is very little loss of medium and fine sand and stone powder, and the grading and fineness modulus of the washed building sand meet the national standards.

The spiral sand washing machine is mainly used in sand and gravel yards, mine dressing plants, building materials, transportation and other industries to clean, grade and dehydrate various ores, rocks and artificial sand.

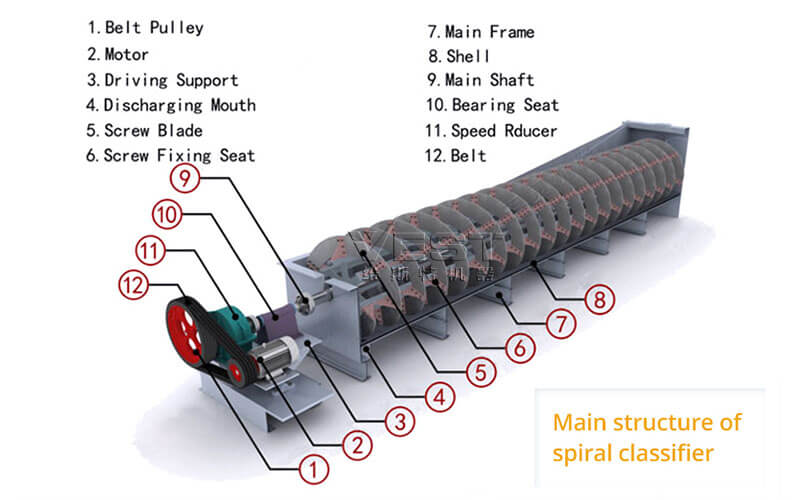

When the spiral sand washing machine works, the constant sharp motor drives the impeller to rotate slowly after the gear slows down through the triangle belt, the reducer, and the gear decelerates.

The sand and stone feed groove enters the washing tank, rolls under the drive of the impeller, and grinds each other to remove the impurities covered with sand and stone, and at the same time destroys the water vapor layer covered with sand particles to facilitate dehydration.

At the same time, add water to form a strong flow, and take away impurities and small dust.

*The output will vary according to different materials, feed particle size and other factors

| Model | Screw Diameter (mm) | Screw Qty (pcs) | Sink length (mm) | Screw Rotate Speed (r/min) | Water Consumption (t/h) | Capacity (t/h) | Power (kw) |

| LX800 | φ800 | 1 | 7620 | 26 | 10-60 | 70-80 | 11 |

| LX920 | φ920 | 1 | 8000 | 21 | 10-90 | 100 | 15 |

| LX1200 | φ1200 | 1 | 8500 | 17 | 20-160 | 150-200 | 15-18.5 |

| LX1500 | φ1500 | 1 | 10000 | 17 | 60-220 | 200-250 | 22 |

| 2LX800 | φ800 | 2 | 7620 | 26 | 10-120 | 150 | 2×11 |

| 2LX920 | φ920 | 2 | 8000 | 21 | 20-160 | 150-200 | 2×15 |

| 2LX1200 | φ1200 | 2 | 8500 | 17 | 40-300 | 350 | 2×18.5 |

| 2LX1500 | φ1500 | 2 | 10000 | 17 | 50-400 | 450 | 2×22 |

*The output will vary according to different materials, feed particle size, and other factors.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.