Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

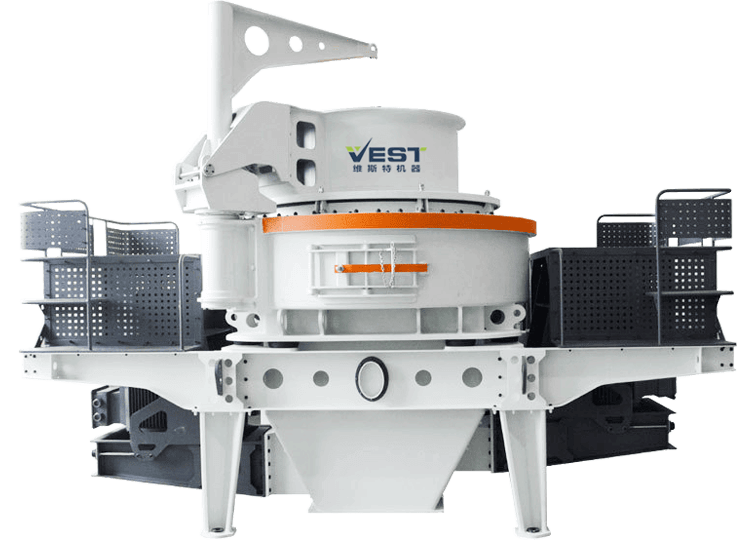

VSI5X/6X sand making machine adopts the crushing principle of combining waterfall and center feeding, which can efficiently process high-hardness stones with a Mohs hardness of more than 7, such as granite and basalt. The output of a single machine reaches 150-640 t/h.

VSI5X/6X sand making machine can crush medium and high hardness stones with Mohs hardness above 7 (such as granite, basalt, pebbles, etc.), and the output of a single machine can reach 150-600 t/h. It is widely used in fine crushing of ores in the fields of construction aggregates, railways, highways, concrete mixing stations, water conservancy, etc.

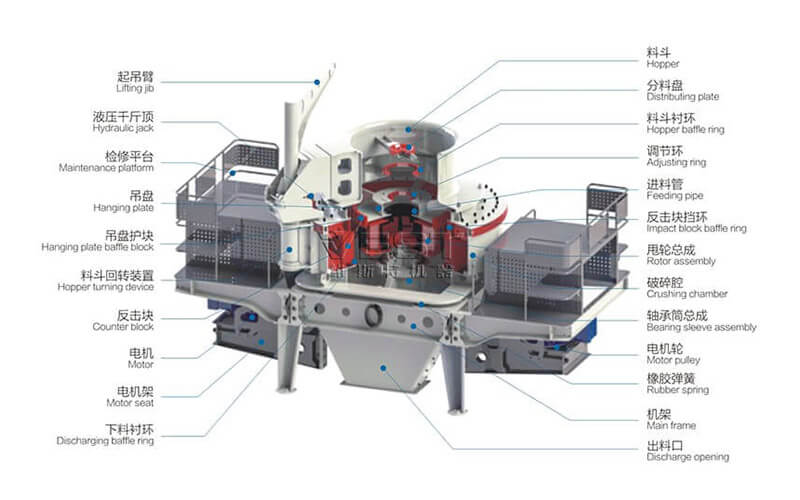

The deep cavity rotor design increases material throughput, and combined with the high-speed rotating impeller, significantly improves crushing efficiency and production capacity.

The detachable combined hammer head design enables partial replacement of worn parts, reduces maintenance costs and extends equipment service life.

It supports three modes: "stone hitting stone", "stone hitting iron" and "waterfall + center feeding" to meet the crushing needs of materials with different hardness.

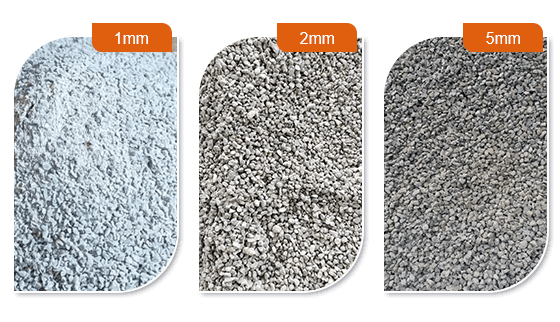

Through the impeller ejection and the impact of materials on the liner, needle-like particles are effectively reduced, and high-quality finished sand with round particles is produced.

VSI5X/6X sand making machine is widely used in many fields such as construction, mining, metallurgy, railway, water conservancy, etc. It is used for medium and fine crushing, shaping and sand making of various hardness stones to produce high-quality finished aggregates and machine-made sand.

Hard stone materials fall into the crusher and are divided into two parts. One part goes into the high-speed-running impeller of the machine, and the other part goes around the impeller.

The two parts materials bump and crush fast during the effect of centrifugal force. Then the materials run like swirls, and bumps, and rub into each other again and again.

The finished products go out from the bottom of the machine, and users can get the requested product size after screening by a vibrating screen.

VEST VSI sand maker adopts central feeding and central cascade feeding ways, which can be changed based on customers’ needs.

*The output will vary according to different materials, feed particle size and other factors

| Model | 5×7615 | 5×8522 | 5×9532 | 5X1145 | 6×1150 | 6×1263 | |

| Capacity(t/h) | Cascade and Center Feeding | 150-280 | 240-380 | 350-450 | 500-640 | 413-442 | 545-583 |

| Center Feeding | 70-140 | 120-200 | 180-290 | 250-360 | 344-368 | 454-486 | |

| Feeder Opening Size(mm) | Soft Material | <40 | <45 | <50 | <50 | <55 | <60 |

| Hard Material | <35 | <40 | <45 | <45 | <45 | <50 | |

| Rotation Speed(r/min) | 1700-1900 | 1500-1700 | 1330-1510 | 1100-1310 | 1000-1300 | 900-1200 | |

| Power of the Double Motors(kw) | 2×75 | 2×110 | 2×160 | 2×220 | 2×250 | 2×315 | |

| Vibrator Sensor | Inspection Scope:0.1-20mm/s,it canbe a djustde continuously | ||||||

| Hydraulic Lubrication Station | Power of Double Oil Pump(kw) | 2×0.25 | |||||

| Safety | Double oil pumps make suresupply of oil with;Stop automatically;Heating start the motorin winter | ||||||

| Overall Dimension(mm) | 8202×5202×1270 | ||||||

| Power of Oil-Box Heater | 2 | ||||||

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.