Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

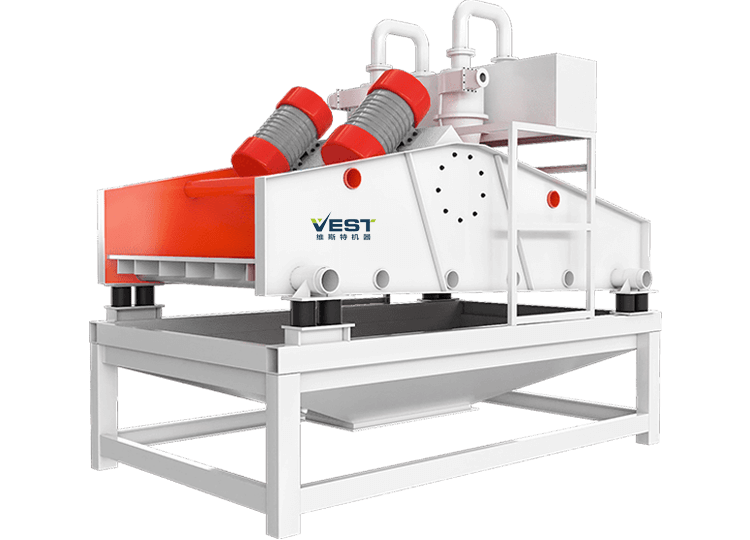

The fine sand recycling machine can recover a large amount of fine sand lost by the sand washing machine. Configuring this machine in the production line can improve economic benefits and reduce environmental pollution.

In the sand production line, the fine sand recycling machine is a relatively important sand recovery equipment. Its main function is to clean, dehydrate and classify sand. It can also be used in the dehydration link of the ceramic raw material processing system, the tailings recovery treatment in the concentrator, the processing system of quartz sand, the processing system of sand in hydropower stations, etc.

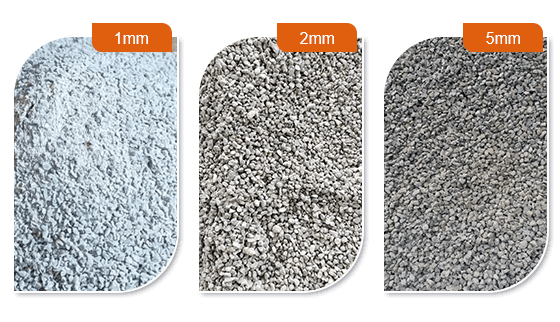

95% of fine sand can be recovered, reducing the loss of fine sand. Improve economic efficiency while reducing environmental pollution.

Fine sand is fully recovered, reducing the workload and cleaning cost of the sedimentation tank.

The dewatering screen adopts polyurethane screen, which has a longer life than other types of screen and is not easy to block holes.

Referring to the national environmental protection standard, the noise is low. It can be equipped with dust removal equipment, and the construction environment fully meets the requirements of environmental protection.

Fine sand recycling machines are mainly used in construction, mining, metallurgy and other industries to recover the fine sand lost during the sand washing process to improve the utilization rate of fine sand, reduce resource waste and environmental pollution.

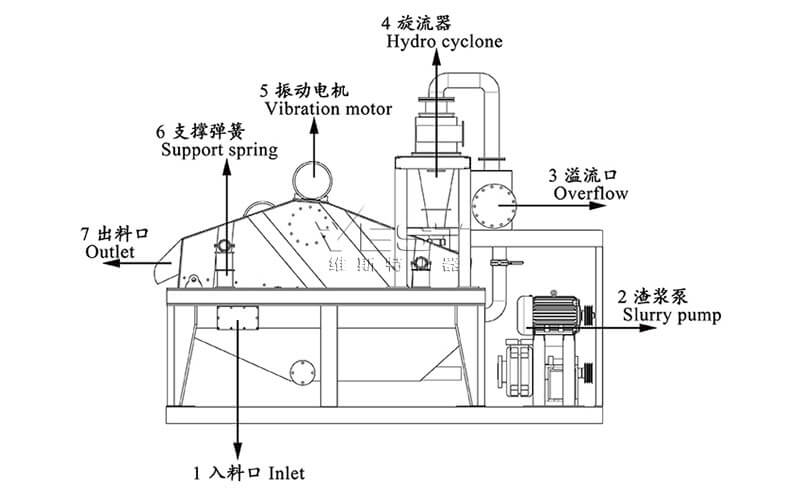

The pump sends the sand and water mixture to the hydrocyclone; the fine sand with eccentricity is sent to the vibrating screen. The fine sand and water are effectively separated after dehydration, and a little fine sand and mud go back to the washing trough.

When the liquid surface of the washing trough is high, the fine sand discharges from the output opening. The linear vibrating screen can recover material with a concentration of 70%–85%.

Adjusting fineness modulus can be realized by changing pump rotation speed, changing pulp consistency, adjusting overflow water, and changing sand sinking mouth. By the process above, the fine sand recovery system can finish three functions, cleaning, dehydration, and grading.

*The output will vary according to different materials, feed particle size and other factors

| Model | Cyclone Size (mm) | Slurry Pump Power (kw) | Size of screen (mm) | Screen Mesh Area(m2) | Screen Motor Power (kw) | Capacity (t/h) |

| VX250-0924 | 250 | 7.5-11 | 900×2400 | 2.16 | 2×0.75 | 30-60 |

| VX300-1224 | 300 | 11-15 | 1200×2400 | 2.88 | 2×1.5 | 50-70 |

| VX350-1224 | 350 | 15 | 1200×2400 | 2.88 | 2×2.2 | 50-80 |

| VX550-1230 | 550 | 22 | 1200×3000 | 3.6 | 2×2.2 | 80-120 |

| VX750-2040 | 750 | 37-45 | 2000×4000 | 8 | 2×11 | 180-200 |

| VX500-1224 | 2×250 | 2×11 | 1200×2400 | 2.88 | 2×2.2 | 70-130 |

| VX600-1530 | 2×300 | 2×15 | 1500×3000 | 4.5 | 2×3 | 80-160 |

| VX700-1530 | 2×350 | 2×15 | 1500×3000 | 4.5 | 2×3 | 150-200 |

| VX900-1530 | 3×300 | 45 | 1500×3000 | 4.5 | 2×3 | 160-220 |

| VX1000-1840 | 4×250 | 2×30 | 1800×4000 | 7.2 | 2×5.5 | 150-240 |

| VX1050-1845 | 3×350 | 45 | 1800×4500 | 8.1 | 2×7.5 | 190-350 |

| VX1100-1840 | 2×550 | 2×22 | 1800×4000 | 7.2 | 2×5.5 | 200-300 |

| VX1200-1845 | 4×300 | 2×30 | 1800×4500 | 8.1 | 2×7.5 | 160-320 |

| VX1400-2445 | 4×350 | 2×30 | 2400×4500 | 10.8 | 2×11 | 250-300 |

| VX1500-2445 | 2×750 | 2×45 | 2400×4500 | 10.8 | 2×11 | 300-400 |

***The output will vary according to different materials, feed particle sizes, and other factors.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.