Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

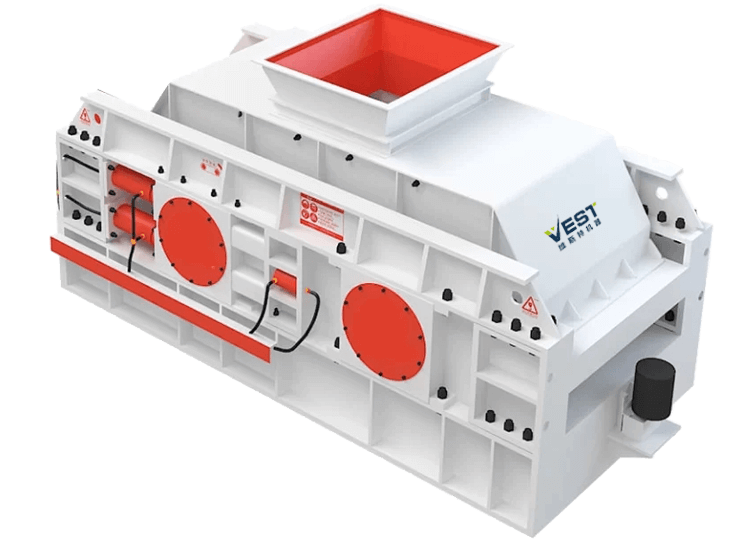

The Double Roller Crusher is a versatile and efficient machine designed for crushing a wide range of materials, from soft to medium-hard substances.

Double Roll Crushers are one of the most widely used crushers in the mining industry and have numerous advantages, such as high capacity, low headroom, low horsepower, the ability to handle wet, sticky feeds, and the ability to produce a cubical product with minimum fines generation. Roll diameters and widths are dictated by the feed size, product size, and capacity.

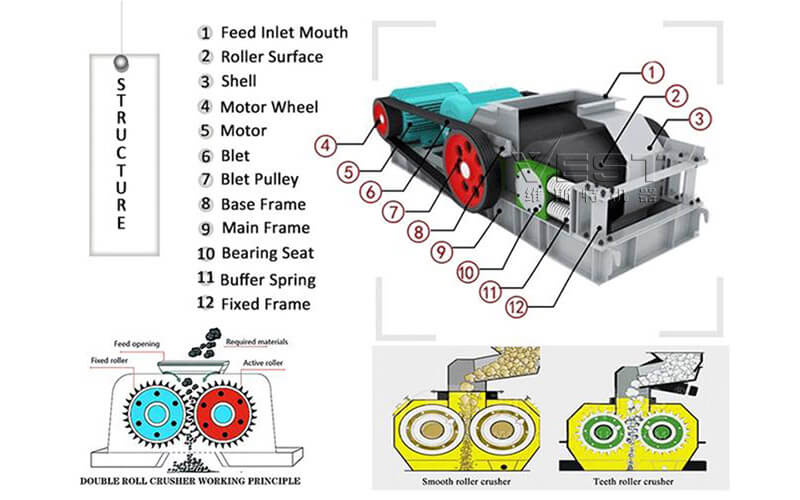

Features two parallel cylindrical rollers that crush materials through compression and shear forces. The gap between the rollers can be adjusted to control the output size.

Ensures high crushing efficiency and uniform product size. Can easily handle a wide range of materials, providing consistent results while generating minimal fines.

High-strength steel and wear-resistant materials withstand heavy loads and abrasive materials. Durable roller surface and bearings ensure long-lasting performance.

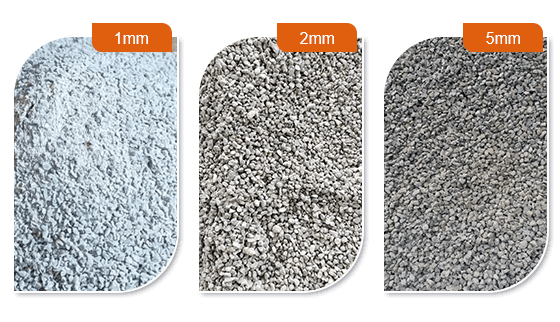

The gap between the rollers can be precisely adjusted to achieve the desired output size. Meets specific requirements for different applications and material types.

Double roll crusher is a common stone crushing equipment, which is mainly composed of two rollers rotating relative to each other. It crushes the material to the required particle size through extrusion, shearing and grinding. Suitable for coal, limestone, gypsum, coke, slag, clay, medium and low hardness ores, etc.

During normal operation, the material is fed between the crushing rolls. A combination of compression and shear forces created between the opposing rolls reduces the feed material to the desired product size while producing a cubicle product with minimum fines.

Vest’s mechanical tramp relief systems employ a spring-and-toggle mechanism that activates whenever an uncrushable object enters the crushing chamber. Once an excessive force is applied to the movable roll, the toggles break open to allow the uncrushable item to pass. The high torsion springs then close the toggles, returning the movable roll to the previous setting. The crusher continues to operate uninterrupted.

Optional features include hydraulic product adjustment, roll scrapers, automatic lubrication, wheeled support bases, and other custom solutions.

*The output will vary according to different materials, feed particle size and other factors

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Dia of roller(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Width of roller(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Feeding size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Outlet port(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

| Motor model | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.