Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

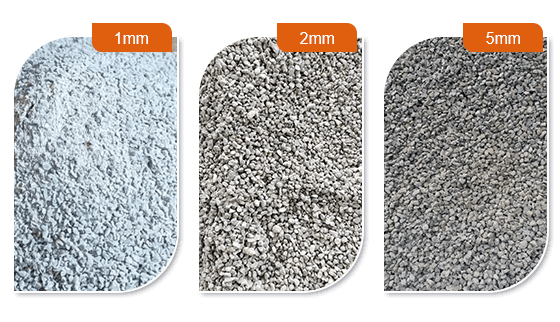

Dewatering screen is a kind of linear dehydrated medium vibrating screen. It is used to remove excess moisture in fine aggregates and sand, and you can achieve moisture content as low as 8%.

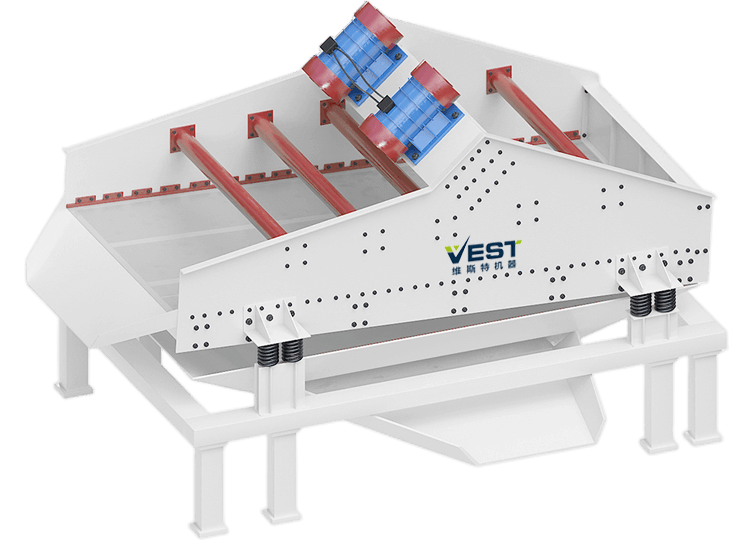

The dewatering screen has efficient dehydration performance, which can quickly remove moisture from the material and greatly reduce the moisture content of the material; at the same time, it also has the characteristics of compact structure and small footprint, and can be flexibly installed on different production lines, effectively saving space and improving production efficiency.

Screens are typically made of high-quality stainless steel or polyurethane, which allows for fine and precise separation. Effectively removes moisture.

By efficiently dewatering materials, the need for additional drying processes is minimized, reducing energy consumption and operating costs.

Robust materials and construction, including heavy-duty frames and impact-resistant screens, are used to ensure long-lasting performance.

Dewatering screens can be customized in size, mesh type, and configuration to meet specific operational requirements. Widely used in various industries.

Dewatering Screens have a wide variety of applications, including dewatering, desliming, degritting, rinsing, scrubbing, sizing, and washing. They are designed to produce a consistent drip-free product and handle materials such as sand, gravel, crushed aggregates, frac sand, industrial sands, mineral sands, hard rock, precious metals ore, coal, iron ore, salt, and other materials.

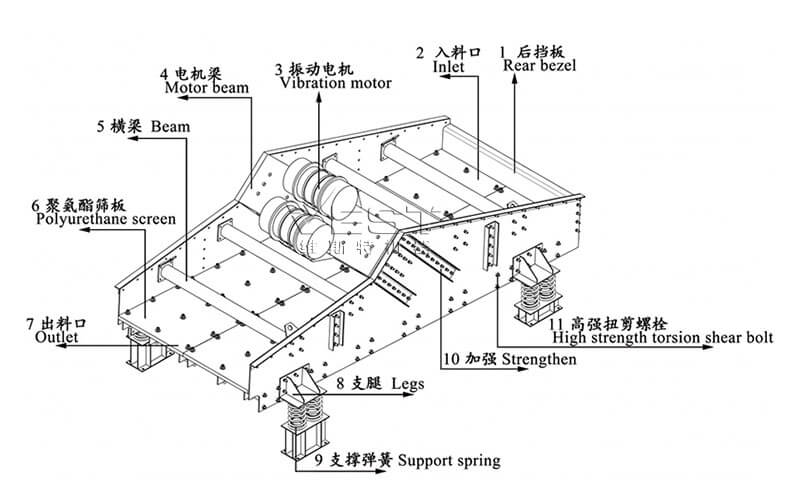

Dewatering screen adopts a double-vibration motor as a power supply. The two motors that rotate synchronously and reversely and centrifugal force are produced by two groups of eccentric blocks. This makes the screen body periodical to-and-fro moving along the direction of a straight line, which is for dehydration.

The slurry passes through the screen and becomes under the screen, while the fine materials are blocked by the screen to form a filter layer and are affected by the vibration force.

Counter-rotating motors create a motion that conveys solids to the discharge end of the screen as water drains through the screen media.

*The output will vary according to different materials, feed particle size and other factors

| Model | Max Feeding Size (mm) | Motor Power (kw) | Capacity (t/h) | Spec of Screen (mm) | Area (m2) | Overall size (mm) |

|---|---|---|---|---|---|---|

| ZSD1230 | ≤10 | 1.9 | 30-80 | 1200×3000 | 3.6 | 3085x1590x1439 |

| ZSD1236 | ≤10 | 2.2 | 30-80 | 1200×3600 | 4.32 | 3677x1590x1600 |

| ZSD1530 | ≤10 | 2.3 | 80-120 | 1500×3000 | 4.5 | 3075×2491×1601 |

| ZSD1536 | ≤10 | 3 | 80-120 | 1500×3600 | 5.4 | 3200×2491×1802 |

| ZSD1836 | ≤10 | 7.5 | 100-140 | 1800×3600 | 6.48 | 3758×3075×1988 |

| ZSD1842 | ≤10 | 7.5 | 100-140 | 1800×4200 | 7.56 | 4368×3075×2000 |

| ZSD1848 | ≤10 | 7.5 | 100-140 | 1800×4800 | 8.64 | 4791×3065×1959 |

| ZSD2442 | ≤10 | 11 | 140-180 | 2400×4200 | 10.1 | 4403×3737×1931 |

| ZSD2448 | ≤10 | 11 | 140-180 | 2400×4800 | 11.52 | 5008×3737×1977 |

| ZSD3048 | ≤10 | 15 | 200-250 | 3000×4800 | 14.4 | 4959×4518×2218 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.