Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

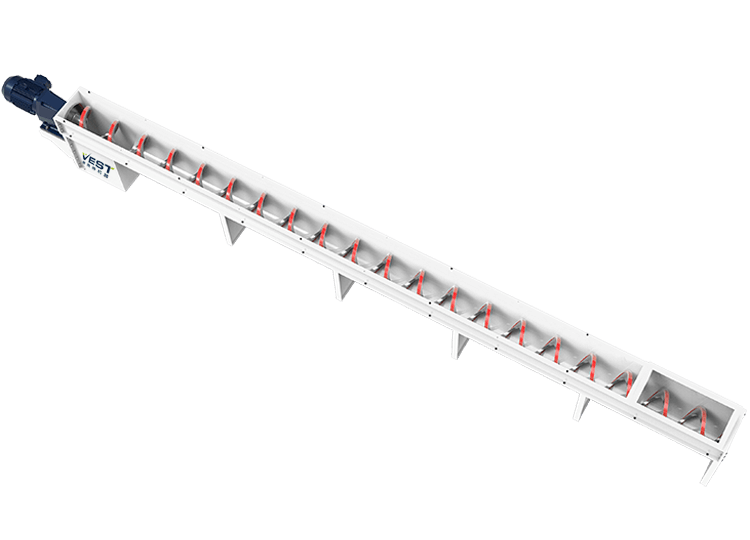

The screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials.

Screw conveyors are versatile material handling systems that use a helical screw blade to move bulk materials. They offer several advantages over other types of conveyors, making them a popular choice in many industries.

The screw conveyor’s vertical or horizontal orientation allows it to be installed in tight spaces or areas with limited headroom, making it ideal for confined environments.

Screw conveyors provide precise control over the flow rate of the material. By adjusting the speed of the screw, you can regulate the amount of material being conveyed.

Their simple design reduces the number of moving parts, which means fewer potential points of failure and lower maintenance costs.

They can be configured for both horizontal and inclined applications, providing flexibility in how they are used.

Screw conveyors are mainly used in chemical, building materials, food, metallurgy, mining and other industries for conveying powder, granular and small block materials in horizontal, inclined or vertical directions.

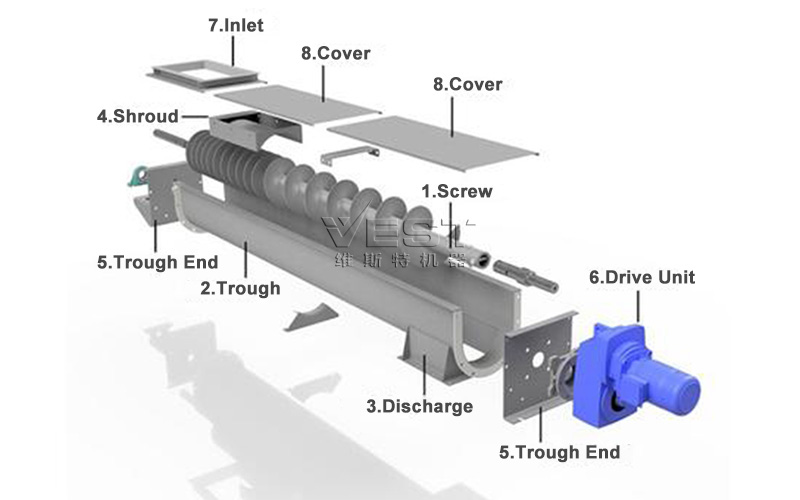

Bulk materials are fed into the conveyor at one end, typically through a hopper or funnel.The drive unit rotates the screw. As the screw rotates, the helical flights push the material along the length of the conveyor.

The shape of the screw and its rotation create a lifting action, moving the material from the inlet to the discharge point. The angle of the screw, along with its diameter, affects the material flow rate.

When the material reaches the discharge end of the conveyor, it exits through an opening, either by gravity or with the help of additional mechanisms.

*The output will vary according to different materials, feed particle size and other factors

| Model | Diameter(mm) | Operation Angle | Max length(mm) | Max capacity (t/h) | Motor power(kw) |

| LSY165 | 165 | 0-60 | 12 | 10 | 2.2-15 |

| LSY219 | 219 | 0-60 | 13 | 30 | 2.2-22 |

| LSY273 | 273 | 0-60 | 15 | 50 | 3-22 |

| LSY325 | 325 | 0-60 | 15 | 80 | 5.5-22 |

| LSY425 | 425 | 0-60 | 18 | 110 | 5.5-22 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.