Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

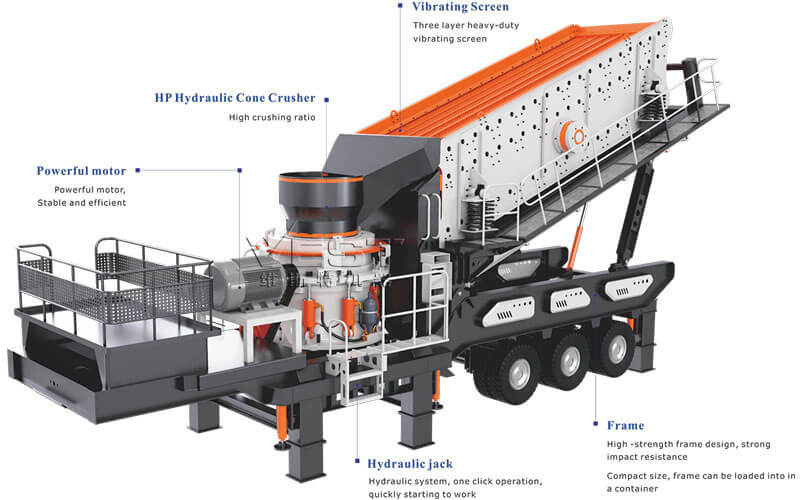

Tire-type mobile cone crusher is a kind of rock crushing equipment with flexible mobility and tires as its traveling device. It can efficiently crush all kinds of hard materials and is widely used in mining, construction and other fields.

Tire mobile cone crusher is mainly used for crushing granite, basalt, iron ore and other hard stones. The feed size is generally ≤300mm and the hourly output is about 50-500 tons.

Equipped with a tire chassis, it can be quickly transferred to other locations without the need for transportation or disassembly, and is adaptable to changing working environments such as mines and quarries.

The cone crusher is used as the main machine to achieve layered crushing, with excellent particle shape and high output (up to 400 tph).

Integrated PLC control system, real-time monitoring of crushing parameters (such as power, discharge port), one-key adjustment, simple operation.

Key components are made of wear-resistant materials and equipped with hydraulic overload protection, with low failure rate and stable and reliable long-term operation.

Tire mobile cone crusher plant are widely used in the field of mining. They can flexibly crush various types of ores at different mining sites to improve mining efficiency. At the same time, they also play an important role in the construction industry, providing high-quality crushed stone for the production of building aggregates to meet the needs of road, bridge and other engineering construction.

The mobile cone crusher relies on the power provided by external electricity or an onboard generator to drive the main engine and auxiliary equipment motors.

The raw material will be fed into the cone crusher chamber to be squeezed and grinded. According to the lamination theory, when the material is subjected to forces in multiple directions, it will be crushed and polished along its texture, and then form stable stone particles.

The crushed stones are returned to the vibrating screen of the mobile cone crusher through the belt conveyor for screening. The screened stones are transported to the finished product area strictly according to different specifications, and the large-sized stones are returned to the cone crusher for re-crushing, and then the screening is repeated until the finished product specifications are reached.

*The output will vary according to different materials, feed particle size and other factors

| VK Mobile Cone Crushing Station (Transportation Size) | ||||

| Model | VK55RS | VK110RS | VK160RS | VK250RS |

| Length(mm) | 11200 | 11800 | 14500 | 15000 |

| Width(mm) | 2743 | 2743 | 3000 | 3000 |

| Height(mm) | 4200 | 4200 | 4400 | 4500 |

| Axle Qty | 2 | 2 | 2 | 3 |

| Weight (ton) | / | / | 35 | 49 |

| Cone Crusher | ||||

| Model | PYB900 | PSG110 | PSG160/HP200/HP430 | HP300/CH440/GP300 |

| Feeding size(mm) | < = 160 | < = 180 | < = 300 | < =300 |

| Discharge adjusting range(mm) | 22-32 | 22-32 | 26-51 | 26-51 |

| Vibrating Screen | ||||

| Model | 3YKR1548 | 3YKR1848 | 3YKR1860 | 3YKR2160 |

| Main Belt Conveyor 1# | ||||

| Model | / | / | B650×7 | B650×7 |

| Side Stacking Belt Conveyor2# | ||||

| Model | / | / | B650×7 | B650×7 |

| Stacking Belt Conveyor 3# Under vibrating screen | ||||

| Model | / | / | B800×7 | B800×9 |

| Note: Product models, parameters , appearance, etc . are constantly being improved. If any modifications cause differences please refer to the actual product received. | ||||

Have Any Questions!

Don't Hesitate To Contact Us Anytime.