Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Crawler jaw crusher with a fully hydraulically driven crawler vehicle chassis, which can meet the customers' requirement of high mobility and high crushing efficiency.

Crawler jaw crusher is mainly used to crush ores, rocks and other materials of various hardness, such as granite, basalt, limestone, etc. Its output varies according to different models, generally reaching tens to hundreds of tons per hour; it has the advantages of flexible mobility, strong adaptability, large crushing ratio, high production efficiency and easy operation and maintenance.

The crawler system provides superior maneuverability, allowing the plant to move easily across rough and uneven surfaces.

Equipped with a powerful jaw crusher, the plant delivers high-performance crushing capabilities, handling a wide range of materials, including hard rocks, ores, and construction debris. The jaw crusher's design ensures optimal size reduction and superior material output.

Ideal for primary crushing in both stationary and mobile operations, the crawler-type jaw crushing plant is suitable for use in quarrying, mining, and recycling applications.

Built to withstand demanding conditions, the plant features a durable and sturdy construction, ensuring long-term reliability and minimal maintenance requirements.

Crawler jaw crusher stations are mainly used in mining, construction aggregate production, road construction, construction waste treatment and other fields, and can perform coarse crushing operations on various types of ores and rocks.

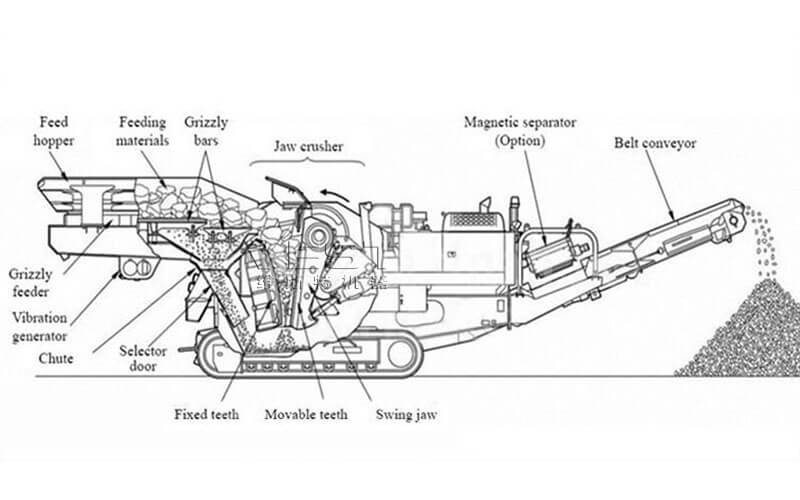

The feeder evenly distributes the materials into the jaw crusher, ensuring a consistent flow and preventing blockages.

The core component of the crawler jaw crushing plant is the jaw crusher. It consists of two main jaws—one fixed and one moving (swing) jaw. The moving jaw is attached to a crank mechanism, which allows it to move back and forth in an oscillatory motion.

Once the material is crushed to the required size, it is discharged through the bottom of the jaw crusher onto a conveyor belt or similar system. This conveyor system transports the crushed material to the next stage in the processing plant or stockpiles it for further use.

*The output will vary according to different materials, feed particle size and other factors

| VTC Crawler Portable Jaw Crushing Plant | ||||||

| Model | TVTC96J | TVTC106J | TVTC116J | TVTC120J | TVTC1380J | TVTC130J |

| Capacity (t/h) | 100-250 | 150-360 | 200-450 | 250-520 | 210-650 | 300-750 |

| Weight (t) | 32 | 45 | 52 | 62 | 63 | 108 |

| L×W×H (mm) | 12450×2500×3100 | 14000×2800×3400 | 15600×3000×3700 | 16000×3000×3700 | 15500×3000×3600 | 19500×3500×3900 |

| Jaw Crusher | ||||||

| Model | C96 | C106 | C116 | C120 | C3054 | C130 |

| Max Feed edge (mm) | 500 | 580 | 650 | 700 | 650 | 800 |

| Motor Power (kw) | 90 | 110 | 132 | 160 | 160 | 160 |

| Vibrating Feeder | ||||||

| Model | GZT/ZSW3895 | GZT/ZSW4211 | GZT/ZSW4211 | GZT1245 | GZT1345 | GZT/ZSW1345 |

| Hopper Volume (m3) | 4 | 5 | 6 | 7 | 7 | 10 |

| Feeding Height (mm) | 3600 | 3900 | 4000 | 4400 | 4000 | 5800 |

| Motor Power (kw) | 11 | 15 | 15 | 15 | 22 | 22 |

| Belt Conveyor | ||||||

| Main Belt Conveyor (m) | B1000-12 | B1000-12 | B1200-13 | B1200-13 | B1200-13 | B1200-13 |

| Discharge Height (mm) | 3200 | 3200 | 3200 | 3400 | 3400 | 3500 |

| Motor Power (kw) | 11 | 11 | 11 | 11 | 11 | 11 |

| Side Belt Conveyor (m) | B500-3.8 | B500-3.8 | B500-3.8 | B500-3.8 | B500-3.8 | B650-4 |

| Discharge Height (mm) | 1800 | 1800 | 1800 | 2200 | 2200 | 2500 |

| Motor Power (kw) | 3 | 3 | 3 | 3 | 3 | 3 |

| Magnetic Separator(Optional) | ||||||

| Model | RCYQ-10 | RCYQ-10 | RCYQ-12 | RCYQ-12 | RCYQ-12 | RCYQ-12 |

| Motor Power (kw) | 3 | 3 | 4 | 4 | 4 | 4 |

| Dual-power Assembly | ||||||

| Driving Mode | Diesel — electricity | |||||

| Note: Product models, parameters, appearance, etc. are constantly being improved. If any modifications cause differences, please refer to the actual product received. | ||||||

Have Any Questions!

Don't Hesitate To Contact Us Anytime.