Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

YKR vibrating screen is a heavy type mechanical device used to separate and classify materials based on their size and shape. Meanwhile, vibrating screen appears in such fields as ore beneficiation, aggregates production, solid waste disposal, and coal dressing.

YKR vibrating screen is a high-efficiency screening machine designed for industrial applications where separation of bulk materials is critical. It operates on a principle of vibration, which enhances its ability to sort and classify materials based on their size and shape.

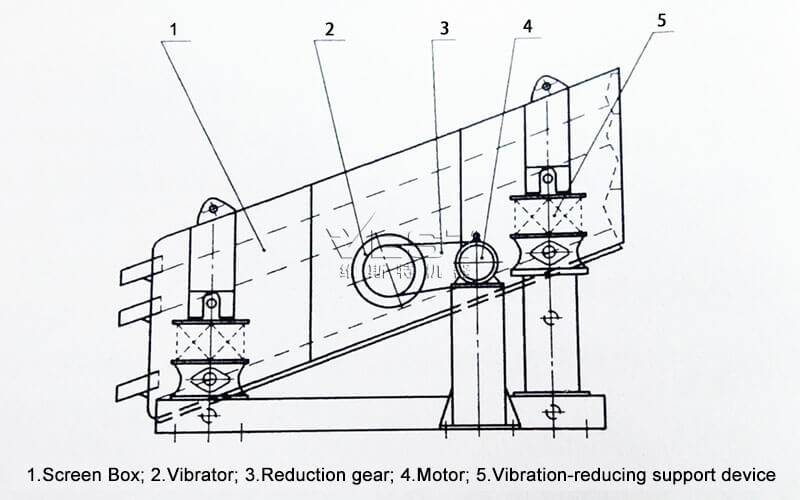

The vibrator adopts block eccentric, external combined and integrated design, and can be lubricated with oil or thin oil automatically.

The flanged side panels, beams, and support seats are connected with high-strength bolts.Vibration elimination technology is used to avoid shaking.

Steel wire screen or polyurethane screen (tension type, combined type) with different mesh sizes can be used. Composite rubber spring is used, which has stable vibration and low noise. Dustproof sealing device is optional.

The frequency, amplitude and angle of the vibrating screen can be adjusted to improve screening efficiency.

ZSW vibrating screens are widely used in mining, building materials, chemical and other industries for material grading, screening, impurity removal and other operations; they are especially suitable for processing medium and fine particle materials, and can provide pre-screening or finished material grading for the crushing system to improve the efficiency of the production line.

The vibrating screen works by using the reciprocating vibration generated by the vibrator excitation.

The upper rotating weight of the vibrator causes the screen surface to produce a plane gyration vibration, while the lower rotating weight causes the screen surface to produce a conical gyration vibration. The combined effect causes the screen surface to produce a complex gyration vibration. Its vibration trajectory is a complex space curve. The curve is projected as a circle on the horizontal plane and an ellipse on the vertical plane.

The amplitude can be changed by adjusting the exciting force of the upper and lower rotating weights. And adjusting the spatial phase angle of the upper and lower weights can change the curve shape of the screen surface motion trajectory and change the motion trajectory of the material on the screen surface.

*The output will vary according to different materials, feed particle size and other factors

| Model | Screen Surface Specification (mm) | Layers | Sieve Pore Size (mm) | Max Feeding Size (mm) | Vibrating Frequency (r/min) | Double Amplitude (mm) | Capacity (t/h) | Power (kw) |

|---|---|---|---|---|---|---|---|---|

| 2YKR1237 | 3700×1200 | 2 | 3-50 | 200 | 970 | 5-9 | 30-100 | 5.5 |

| 3YKR1237 | 3700×1200 | 3 | 3-50 | 200 | 970 | 5-9 | 30-100 | 7.5 |

| 2YKR1548 | 4800×1500 | 2 | 3-2000 | 400 | 970 | 5-9 | 30-275 | 15 |

| 3YKR1548 | 4800×1500 | 3 | 3-2000 | 400 | 970 | 5-9 | 30-275 | 15 |

| 2YKR1848 | 4800×1800 | 2 | 3-2000 | 400 | 970 | 5-9 | 56-330 | 18.5 |

| 3YKR1848 | 4800×1800 | 3 | 3-2000 | 400 | 970 | 5-9 | 56-330 | 18.5 |

| 4YKR1848 | 4800×1800 | 4 | 3-80 | 400 | 970 | 5-9 | 56-330 | 22 |

| 2YKR1860 | 6000×1800 | 2 | 3-2000 | 400 | 970 | 5-9 | 65-586 | 18.5 |

| 3YKR1860 | 6000×1800 | 3 | 3-2000 | 400 | 970 | 5-9 | 65-586 | 22 |

| 4YKR1860 | 6000×1800 | 4 | 3-2000 | 400 | 980 | 5-9 | 65-586 | 30 |

| 2YKR2160 | 6000×2100 | 2 | 3-2000 | 400 | 980 | 5-9 | 81-720 | 22 |

| 3YKR2160 | 6000×2100 | 3 | 3-2000 | 400 | 970 | 5-9 | 81-720 | 30 |

| 4YKR2160 | 6000×2100 | 4 | 3-2000 | 400 | 980 | 5-9 | 81-720 | 37 |

| 2YKR2460 | 6000×2400 | 2 | 3-2050 | 400 | 970 | 5-9 | 100-810 | 22 |

| 3YKR2460 | 6000×2400 | 3 | 3-2050 | 400 | 980 | 5-9 | 100-810 | 30 |

| 4YKR2460 | 6000×2400 | 4 | 3-2050 | 400 | 980 | 5-9 | 150-850 | 37 |

| 2YKR3080 | 8000×3000 | 2 | 3-2000 | 400 | 980 | 5-9 | 220-1000 | 37 |

| 3YKR3080 | 8000×3000 | 3 | 3-2050 | 400 | 980 | 5-9 | 220-1000 | 45 |

| 4YKR3080 | 8000×3000 | 4 | 3-2050 | 400 | 980 | 5-9 | 220-1000 | 55 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.