Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

What is Ferrosilicon? What is it Used For?

Ferrosilicon is an iron-silicon alloy made of coke, steel scraps, and quartz (or silica) through electric furnace smelting. Because silicon and oxygen can easily form silicon dioxide, ferrosilicon is often used as a deoxidizer in steelmaking. It can also be used as a reducing agent in ferroalloy production and chemical industry, and is widely used.

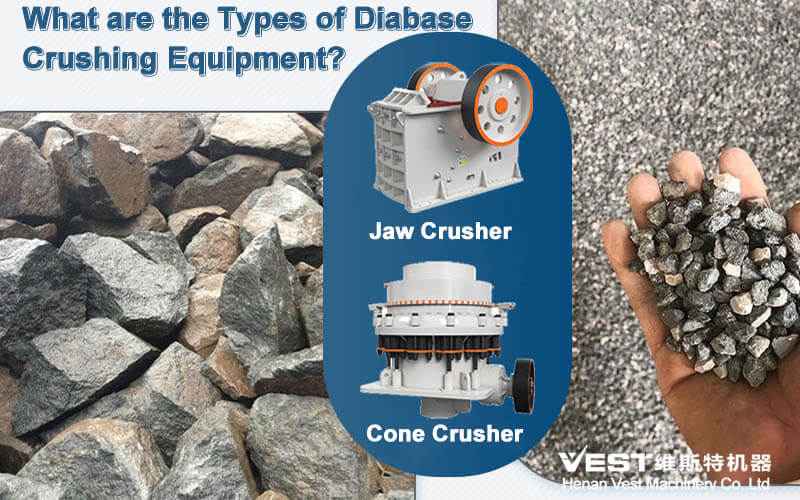

Ferrosilicon is brittle and is usually processed by a crusher. However, there are many types of Stone Crusher Machine currently sold on the market, and customers can choose the appropriate model according to actual needs.

When it comes to choosing a suitable crusher, many users think of jaw crushers, and some users directly consult Ferrosilicon Jaw Crushers. Which model should I choose for 50 t/h? VEST Machine recommends that you refer to PE 400×600.

Ferrosilicon Jaw Crusher, 50 TPH, It is Recommended to Choose PE 400×600

1. The processing capacity of PE 400×600 Jaw Crusher ranges from 15-60t/h. Because ferrosilicon is brittle and easy to break, we refer to the maximum processing capacity of the jaw crusher. The feed port size of this model crusher is 400×600mm, the feed particle size is 340mm, and the discharge port adjustment range is 40-100mm;

2. If you consider that there are many complex situations under actual production conditions, which may affect production capacity, then PE500×750 jaw crusher will definitely meet your processing needs.

PE 500×750 Jaw Crusher has a processing capacity of 40-110t/h, a feed port size of 500×750mm, a feed particle size of 425mm, and a discharge particle size of 50-100mm.

What are the Advantages of Ferrosilicon Jaw Crusher?

1. Better steel materials are used to extend the life of parts

The operating conditions of mining machinery and equipment are usually harsh and the wearing parts are worn out quickly. VEST machines use high-quality high-manganese steel castings in the selection of core parts, which are wear-resistant and durable, extending the service life of core parts.

2. Overload protection, ensuring production safety anytime and anywhere

The toggle plate transmission device designed by VEST machine can be automatically broken. When the material that cannot be crushed falls into the crusher, the jaw crusher will start the hydraulic overload protection, so that the equipment stops working in time to avoid causing greater damage and ensure production safety.

3. Hydraulic control and convenient cavity cleaning

The new jaw crusher is equipped with a hydraulic oil station to ensure that the lubricating parts required by the machine can be supplied with oil in time to ensure safe operation. And if the crusher stops under load, the hydraulic cavity cleaning system can quickly clean the crushing cavity, reducing downtime.

4. Wedge block discharge device, flexible adjustment of discharge particle size

Modern jaw crushers use wedge block discharge port adjustment system, so that the machine can adjust the discharge port to the preset value within a few minutes even when idling. With the cooperation of the hydraulic system, it can be automated, which is simpler, safer and faster than the old gasket type discharge port adjustment system.

The above is an introduction to the advantages of the new ferrosilicon jaw crusher. If you want to know more information (quotation, other models, after-sales service, etc.), please leave a message or WhatsApp with us.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online