Phone/Wechat/Whatsapp:+86-15538359886

Phone/Wechat/Whatsapp:+86-15538359886

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-15538359886

Phone/Wechat/Whatsapp:+86-15538359886

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

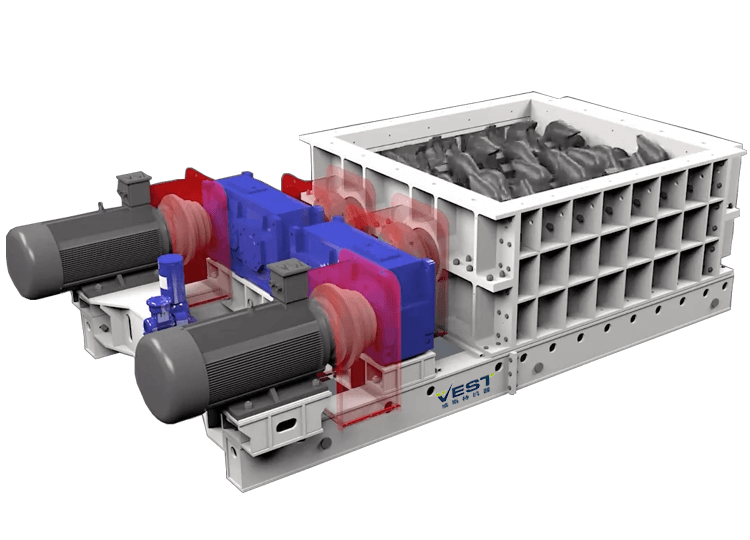

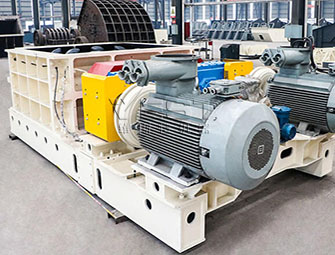

VEST mineral sizers are designed to process a wide range of materials including copper, iron ore, gold, nickel, lithium/spodumene, coal, potash, phosphates and other hard rock and soft non-coal minerals.

Mineral sizers are commonly used to process hard rock minerals including gold, iron, copper and nickel ores, as well as soft non-coal minerals, low capacity battery minerals, rare earth minerals such as spodumene, antimony and cobalt.

Due to its unique crushing principle, the VEST mineral sizer can quickly and efficiently process materials ranging from soft (30MPa) to hard rock (250MPa), and it is no problem to achieve an hourly output of thousands of tons.

The VEST mineral sizer can adjust the particle size of the finished product by controlling the gap between the rollers. Compared with other crushing equipment, it produces very little dust and fine matter.

VEST sizer can not only process wet sticky materials, but also dry hard rocks. It is no problem to process wet sticky materials and dry hard rocks at the same time.

The VEST sizer is equipped with an overload protection device to effectively prevent the equipment from being damaged by the entry of materials that cannot be crushed. In addition, the VEST sizer is also equipped with a PLC control system, which can realize remote automatic control and monitoring, which not only ensures the continuous and stable operation of the equipment, but also reduces labor costs.

Mineral sizers can also perform primary, secondary and tertiary crushing operations on a variety of minerals such as coal, salt, gypsum, phosphate, limestone, bauxite, petroleum coke, lignite, natural soda, carbon anode, oil sands, clay, shale, etc.

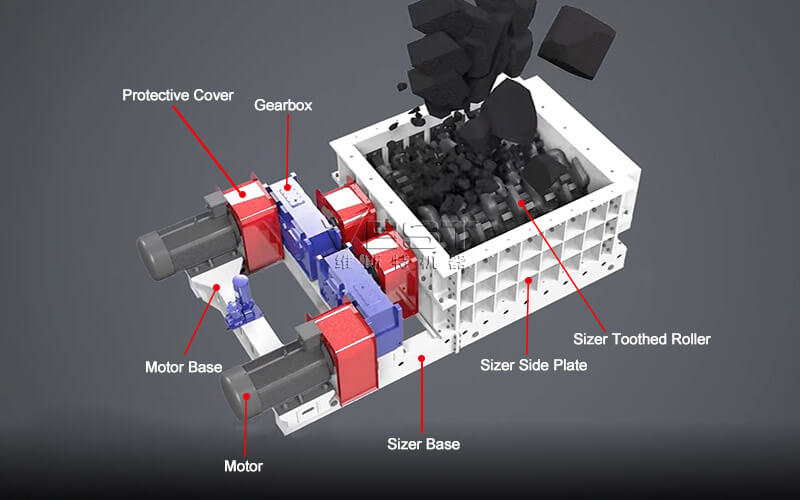

The mineral sizer is equipped with two inward rotating toothed rollers equipped with replaceable crushing teeth. The material can be fed to the toothed roller at a constant speed through a plate or chain feeder.

1. The material is squeezed by the rotor teeth on both sides, so that it is crushed along the natural texture.

2. Materials that reach standard size will be discharged from the middle or around the roller. The incompletely crushed materials are further crushed by the rotor teeth and the fixed teeth of the crushing rod, and then the materials are crushed to the required size.

3. The maximum feed size of the mineral sizer is 1200 mm (47 inches) and can be crushed to 300 mm (12 inches). In addition, the size of the finished product can be adjusted by adjusting the gap between the rollers.

*The output will vary according to different materials, feed particle size and other factors

| Model | 2PLF800 | 2PLF1000 | 2PLF1200 | 2PLF1500 |

| Teeth Roller Dia (mm) | 800 | 1000 | 1200 | 1400 |

| Roll length (mm) | 1500-2500 | 1500-3000 | 1500-3000 | 2000-3500 |

| Max feed size (mm) | 800 | 1000 | 1200 | 1500 |

| Output size (mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity (t/h) | ≤2000 | ≤3500 | ≤6000 | ≤10000 |

| Model | 2PLS800 | 2PLS800 | 2PLS1000 | 2PLS1200 |

| Teeth Roller Dia (mm) | 600 | 800 | 1000 | 1200 |

| Roll length (mm) | 1000-2500 | 1500-3000 | 2000-3500 | 2000-4000 |

| Max feed size (mm) | 200 | 300 | 350 | 400 |

| Output size (mm) | 50-80 | 50-100 | 50-120 | 50-140 |

| Capacity (t/h) | 250-800 | 500-2000 | 600-3000 | 800-4000 |

Have Any Questions!

Don't Hesitate To Contact Us Anytime.