Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

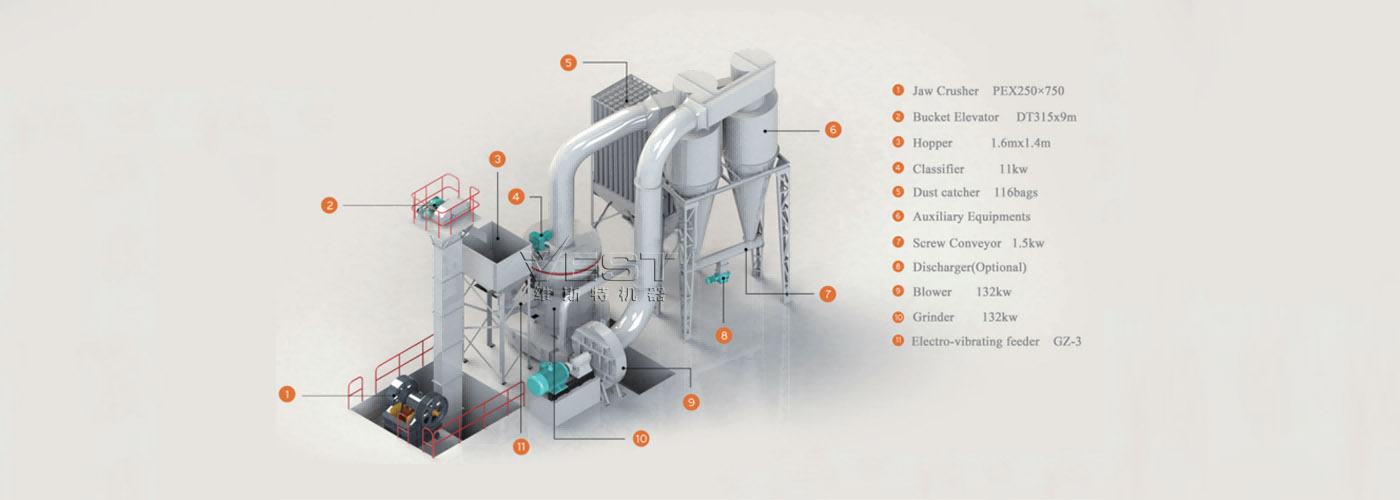

Gypsum grinding production line is mainly used to process gypsum raw materials into standard building gypsum powder or gypsum powder for other industrial purposes. Its finished products are widely used in building materials, construction, power plant desulfurization, non-metallic mineral powder making and other fields.

Crushing Part | PE250x750 Model Jaw Crusher Power: 22kw To crush big stones (<210mm) to below 25mm |

Bucket Elevator | TH315x10M Model To convey the crushed limestone to the grinding mill |

Transfer Silo | Buffering the inflow of materials |

Feeder | GZ3F Model Fully enclosed electromagnetic vibrating feeder |

YGM Mill | YGM160 Main Mill Power: 185kw Powder Classifier: 30 |

Dust Removal | Double Cyclone Collector DMC80 Bag Dust Collector Blower: 200kw |

Powder Conveyo | LS315 Screw Conveyor |

Powder Collecting | In general, it is recommended to use the finished product bucket to lift it to the finished product silo for collection.

The height of the finished product bucket and the silo capacity are determined by the manufacturer based on the actual situation on site and under the guidance of the manufacturer. |

If you can't find other products, please contact customer service

PE Series Jaw Crusher

PE Jaw crusher is one traditional primary or secondary crushing equipment used to crush stone below ···

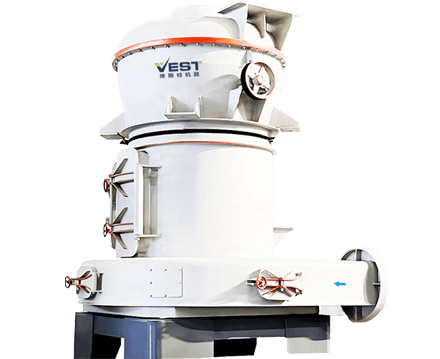

YGM Raymond Grinding Mill

YGM grinding mill is an advanced version of Raymond grinding mill. It is a high-pressure suspension ···

1. Efficient grinding and stable production capacity

The grinding structure is optimized according to the low hardness of gypsum (Mohs hardness 1.5-2), and it is equipped with high wear-resistant roller sleeves and grinding rings, which have a long service life and high output, greatly meeting the users' large-scale production needs.

2. Adjustable fineness

By adjusting parameters such as the classifier speed and grinding roller pressure, the fineness of the finished product can be accurately controlled within the range of 80-300 mesh (or even higher), which is suitable for the material standards of multiple fields such as building gypsum powder, desulfurized gypsum, and gypsum boards.

3. Energy saving, environmental protection and low consumption

The pulse dust removal system and sealed grinding chamber are used, and the dust emission is lower than the national standard; with energy-saving motors and intelligent control systems, the energy consumption is reduced by 15%-20% compared with traditional processes, which meets the requirements of green production.

4. Strong adaptability of raw materials

It can process raw materials in different forms such as natural gypsum ore and desulfurized gypsum (industrial waste), support direct grinding of materials with a moisture content of ≤15%, reduce pretreatment steps, and improve production line flexibility.

5. Simple operation and maintenance with controllable costs

Because gypsum grinding causes little wear and tear, the life of core components is long (e.g. the roller sleeve replacement cycle is extended by 30%), and the equipment is compact, with ample maintenance space, daily maintenance is convenient, and the overall operating costs are significantly reduced.