Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

As the core equipment of mining, building materials, chemical industry and other industries, Ball Mill Machine has become an indispensable part of material crushing process with its strong material adaptability and precise particle size control ability.

Introduction to Ball Mill

A ball mill is a Grinding Mill Machine equipped with grinding balls, which is used to grind or mix materials used in mineral processing, paint, fireworks, ceramics and selective laser sintering. It works based on the impact and grinding

principle: when the ball falls from near the top of the shell, it is reduced in size through multiple impacts.

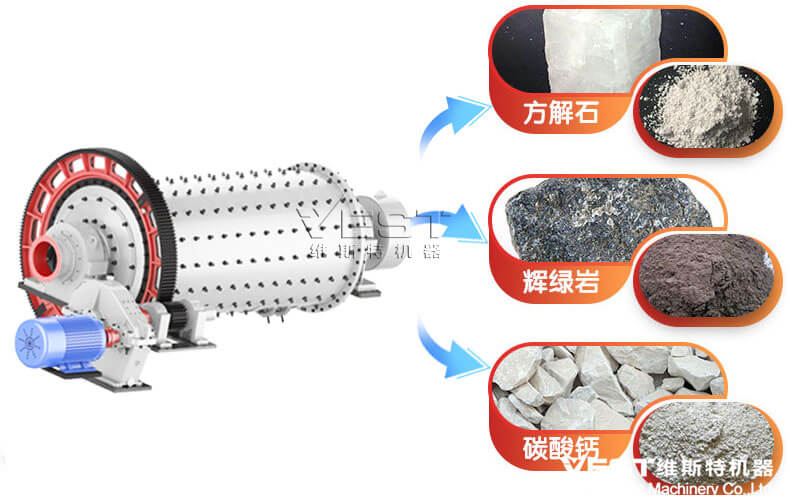

What Materials Can be Ground By Ball Mill?

Industrial ball mill uses grinding media such as steel balls or ceramic balls to impact and rub the material, and can handle almost all common solid materials. They can be divided into categories:

1. Metal ore materials:

Metal ores such as iron ore, copper ore, rock gold ore, etc., which are ground into fine powder for smelting or mineral processing.

2. Hard non-metallic materials:

(1) Ceramics (such as alumina and silicon carbide) are used for electronic components or structural materials;

(2) Glass powder is used in the manufacture of optical or special glass;

(3) Minerals (such as coal and quartz) meet the needs of building materials, metallurgy and other fields.

3. Special functional materials:

(1) New energy battery materials (lithium cobalt oxide, lithium manganese oxide);

(2) Magnetic materials, electronic ceramics and other electronic industrial raw materials;

(3) Pharmaceutical raw materials or catalysts, which require ultra-fine grinding to improve reaction activity.

The wide applicability of this material stems from its compatibility with different physical properties: high-impact crushing of hard and brittle minerals, gentle grinding of soft polymers to prevent degradation, and even efficient processing of fiber materials.

How Many Meshes Can be Achieved in Grinding?

Fineness is a key indicator for measuring the performance of a ball mill, which is affected by the type of equipment, process parameters and material characteristics:

Conventional ball mill: The general grinding fineness range is 24–200 mesh (0.89 mm–0.074 mm), which meets most industrial scenarios such as cement preparation or ore dressing coarse grinding.

Ultrafine grinding technology: Special ultrafine ball mills (such as tower mills and high-frequency vibration mills) can stably produce 300 mesh (0.048 mm) and above fineness, which is suitable for processes such as gold cyanide leaching that need to avoid moisture or extremely fine dissociation.

Some equipment can even reach an ultrafine particle size of -320 mesh (<42 μm) by optimizing the grading system (such as the discharge grading box + return port design), which is used for high value-added materials such as nano powders or high-end ceramics.

Summary:

From large-scale crushing of metal ore materials to precise preparation of pharmaceutical nano powders, ball mills are based on 200 mesh, advanced to 300 mesh, and ultrafine 320 mesh as the forefront, continuously promoting the efficiency and limit of material processing in various industries. Its technical adaptability is constantly expanding, becoming an important carrier of modern industrial particle design.

Phone/Wechat/Whatsapp:+86-15538359886

Phone/Wechat/Whatsapp:+86-15538359886

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online