Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

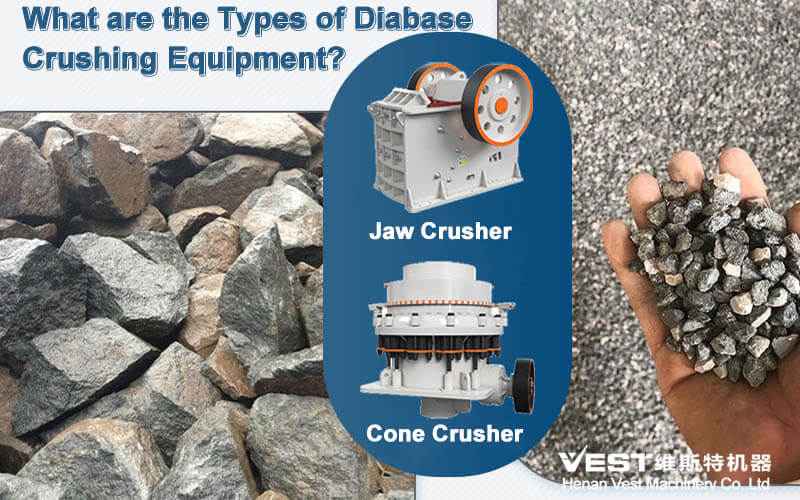

The maximum rock size that a jaw crusher allows to crush is mainly determined by its feed opening width, which is usually 75%~85% of the feed opening width. Specific adjustments need to be made based on equipment model, rock characteristics and working conditions.

Next, VEST Machinery will give you a detailed introduction to the maximum size allowed for crushing by the Rock Jaw Stone Crusher. I hope it will be of some help to you.

1. Key Determining Factor: Feed Inlet Size

Feed Opening Width: usually determines the maximum allowable size of the rock. For example, if the feed opening width is 1.5 meters, the maximum rock length that can be processed is about 1.2-1.3 meters (about 80-85% of the width).

Feed Port Depth: affects the equipment’s ability to accommodate long strips of rock and needs to be selected based on the shape of the rock.

2. Typical Treatment Range

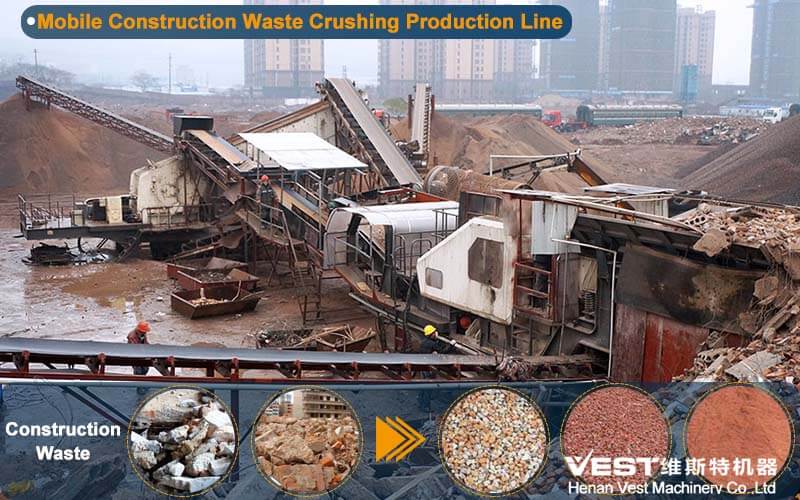

Small and Medium-Sized Equipment: Common processing sizes are 300mm to 1 meter, suitable for construction waste or small and medium-sized mines.

Large/extra-Large Equipment: The maximum feed opening width can reach 1.5-2 meters, and can handle giant rocks with a side length of 1.2-1.7 meters, which is often seen in mining or aggregate production.

3. Actual Influencing Factors

1) Rock Shape

Flake or Long Strip Rock: The long side size needs to be limited (usually not more than 0.8 times the width of the feed inlet) to avoid material jamming.

Cubes or Spheres of Rock: Allowed to approach the theoretical maximum.

2) Rock Hardness

High-Hardness Rock (such as granite, basalt): It is recommended to reduce the feed size to 70%~80% of the theoretical value to reduce jaw plate wear.

3) Equipment Adjustment Parameters

Moving Jaw Stroke: The larger the stroke, the stronger the crushing force, but too large a stroke can easily lead to vibration, so the feed size needs to be balanced.

Discharge Opening Adjustment: When the discharge opening is small, it is recommended to reduce the feed size to improve efficiency.

4. Selection Recommendations

Calculation Rule: Maximum feed size ≈ feed opening width × 0.8 (conservative value).

Safety Margin: The actual feed is recommended to be 10-15% smaller than the theoretical maximum value to ensure continuous and stable operation.

Supporting Design: The front end needs to be equipped with suitable feeding equipment (such as a vibrating feeder) to avoid direct impact from oversized materials.

5. Industry Case Reference

C Series Jaw Crusher (famous brand – VEST machinery): C160 model feed opening 1.2m×0.8m, recommended maximum feed 1m.

Mining Application: When processing iron ore, 2m wide feed port equipment is often configured to allow 1.6m ore to enter the crusher directly.

No matter what kind of Rock Crusher Equipment, it has its maximum feed size. We can choose the stone size suitable for the crusher according to the above suggestions.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online